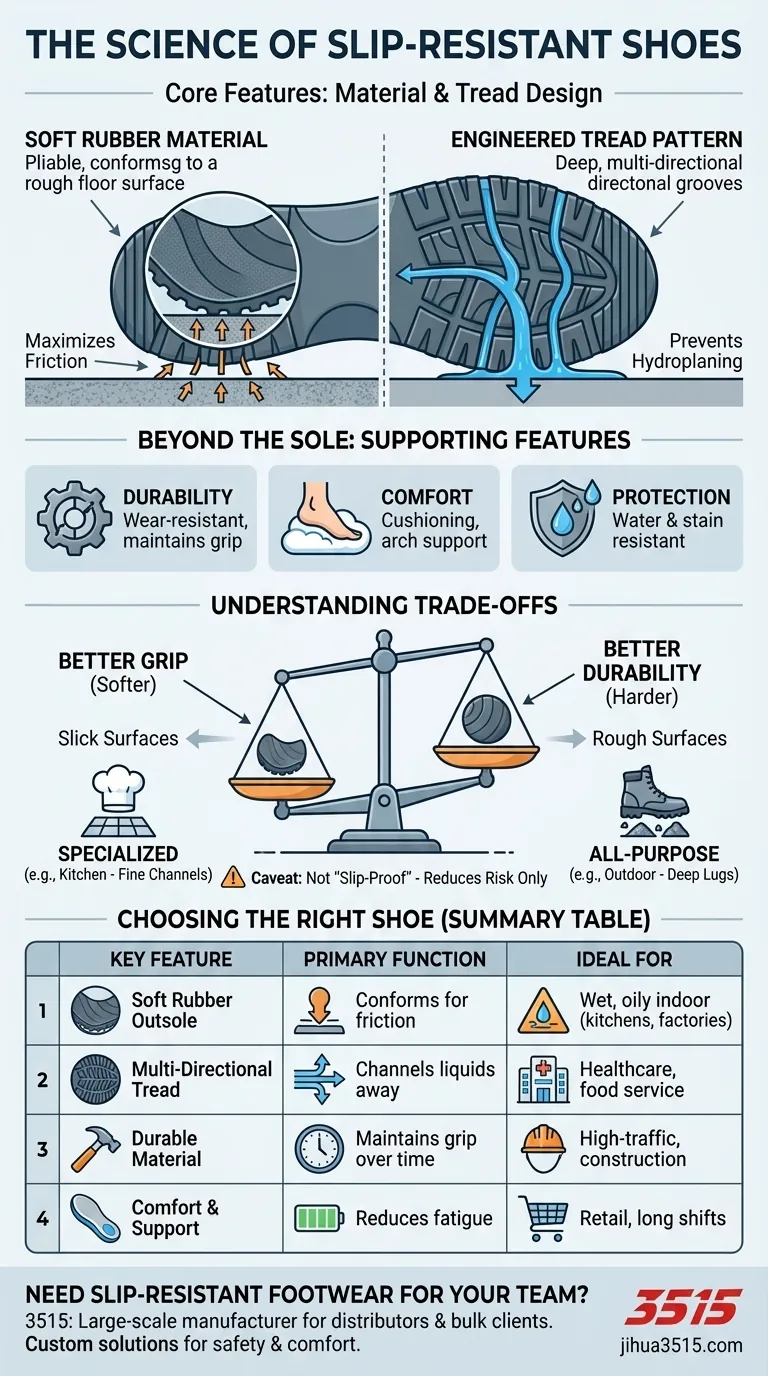

At its core, a shoe's slip resistance comes down to two critical features: the material of its outsole and the design of its tread pattern. These elements work together to maximize friction and channel away liquids, providing a stable grip on surfaces where standard shoes would fail.

The most effective slip-resistant shoes are not just about a single feature, but an integrated system. They combine advanced rubber compounds with meticulously engineered tread patterns to actively manage contaminants like water and oil, ensuring the sole maintains maximum contact with the ground.

The Foundation of Grip: The Outsole System

The outsole—the very bottom of the shoe that contacts the floor—is where the engineering of slip resistance truly happens. It's a system of material, pattern, and design working in concert.

The Critical Role of Material

The primary material used for slip-resistant outsoles is soft, high-quality synthetic rubber. Unlike the harder, often plastic-like materials in fashion footwear, this specialized rubber is formulated to be pliable.

This flexibility allows the sole to conform to microscopic imperfections in a floor's surface, significantly increasing the contact area and, therefore, the level of friction.

The Science of Tread Patterns

The tread pattern is not merely for style; it's a functional channeling system. Effective patterns feature deep, multi-directional grooves or channels.

When you step on a wet or oily surface, these channels quickly divert the liquid out from under the shoe. This prevents a layer of fluid from forming between the sole and the floor—a phenomenon known as hydroplaning—which is a primary cause of slips.

How Shape and Design Contribute

The overall design of the sole also plays a part. A flatter, wider sole profile can increase the surface area in contact with the ground. Small, circular patterns within the larger tread can create additional suction on smooth, wet floors, further enhancing grip.

Beyond the Sole: Essential Supporting Features

While the outsole does the heavy lifting, other features determine whether a shoe is truly effective and practical for its intended environment.

Durability for Consistent Safety

A slip-resistant shoe is only effective as long as its tread is intact. The outsole must be made from wear-resistant materials that can withstand constant use without the tread pattern becoming smooth and ineffective.

Frequent replacement is not just a matter of cost; it's a matter of safety. A worn-down shoe is a hazard.

Comfort for All-Day Wear

Safety features are useless if the shoes are too uncomfortable to wear. Key comfort elements include ample cushioning and robust arch support to reduce fatigue during long shifts.

A roomy toe box is also important, as it allows for natural foot swelling that occurs throughout the day, preventing pain and discomfort.

Resistance to Workplace Hazards

For many environments, the shoe's upper must also offer protection. Water and stain resistance is critical in kitchens and medical settings, making the shoes easier to clean and maintain. This helps ensure both hygiene and longevity.

Understanding the Trade-offs

Choosing the right shoe involves balancing competing factors. No single design is perfect for every situation.

Grip vs. Durability

There is often a trade-off between grip and longevity. Softer rubber compounds provide superior grip on slick, smooth surfaces, but they also tend to wear down more quickly than harder compounds.

Harder rubber is more durable for rough surfaces like concrete or asphalt but may offer less friction on a wet tile floor.

Specialized vs. All-Purpose Designs

A shoe optimized for an oily commercial kitchen has a different tread design than one made for icy outdoor walkways. The former uses fine, intricate channels for liquids, while the latter uses deep, aggressive lugs for mechanical grip.

Using a shoe outside its intended environment can significantly reduce its effectiveness.

The Limits of "Slip-Resistant"

It is crucial to understand that no shoe is "slip-proof." The term "slip-resistant" indicates that the footwear is designed to reduce the risk of slips, not eliminate it entirely. User awareness and caution remain essential components of workplace safety.

How to Choose the Right Shoe for Your Environment

Selecting the correct shoe requires matching its specific features to the demands of your workplace and role.

- If your primary focus is a wet or oily indoor surface (e.g., kitchen, factory): Prioritize shoes with soft rubber soles and dense, intricate tread patterns designed to channel away liquids.

- If your primary focus is varied or uneven terrain (e.g., construction, outdoor work): Look for durable soles with deeper, more aggressive lugs for mechanical grip and stability.

- If your primary focus is all-day comfort during long shifts (e.g., healthcare, retail): Ensure the shoe combines a certified slip-resistant outsole with excellent cushioning, arch support, and a lightweight design.

Ultimately, choosing the right footwear is an exercise in matching the shoe's engineered purpose to your specific safety needs.

Summary Table:

| Key Feature | Primary Function | Ideal For |

|---|---|---|

| Soft Rubber Outsole | Conforms to floor for maximum friction | Wet, oily indoor surfaces (kitchens, factories) |

| Multi-Directional Tread | Channels liquids away to prevent hydroplaning | Healthcare, hospitality, food service |

| Durable, Wear-Resistant Material | Maintains grip and safety over time | High-traffic environments, construction |

| Comfort & Support Features | Reduces fatigue for all-day wear | Retail, healthcare, long shifts |

Need the right slip-resistant shoe for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified slip-resistant footwear for distributors, brand owners, and bulk clients. Our expertise ensures your workforce gets the perfect combination of safety, comfort, and durability for their specific environment—from soft-soled shoes for kitchens to durable boots for outdoor work.

Contact our experts today for a custom solution that protects your people and your business.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- How can you tell if shoes are slip-resistant when shopping online? A Practical Guide to Safety

- What is the technical purpose of requiring full-coverage work shoes in food factories or catering kitchens? Ensure Safety & Hygiene Standards

- Why is a high-performance anti-slip outsole essential for single-leg exoskeleton users? Ensure Stability and Safety

- What is the significance of high-performance non-slip outsoles? Enhance Stability for Balance & Sensory Challenges

- What is the function of using a 90 wt percent glycerol solution as a lubricant? Simulated Slip Resistance Explained

- What are the main components of a slip-resistant shoe? Unpacking the Anatomy of Workplace Safety

- What types of non-slip shoes are recommended for outdoor activities? Find Your Perfect Traction Solution

- What is the purpose of the tread pattern on non-slip shoes? Master Fluid Dynamics for Ultimate Grip