At its core, the significance of the Goodyear welt is its design for longevity and repair. This method of shoe construction, developed by Charles Goodyear in 1872, involves stitching a strip of leather—the welt—to the shoe's upper and insole. This technique creates an incredibly durable, water-resistant shoe that can be resoled multiple times, transforming it from a disposable good into a long-term asset.

The true value of a Goodyear welt is not just its robust build, but its fundamental architecture for serviceability. By isolating the sole from the upper, it ensures the shoe can be repeatedly renewed, making it a more economical and sustainable choice over its entire lifespan.

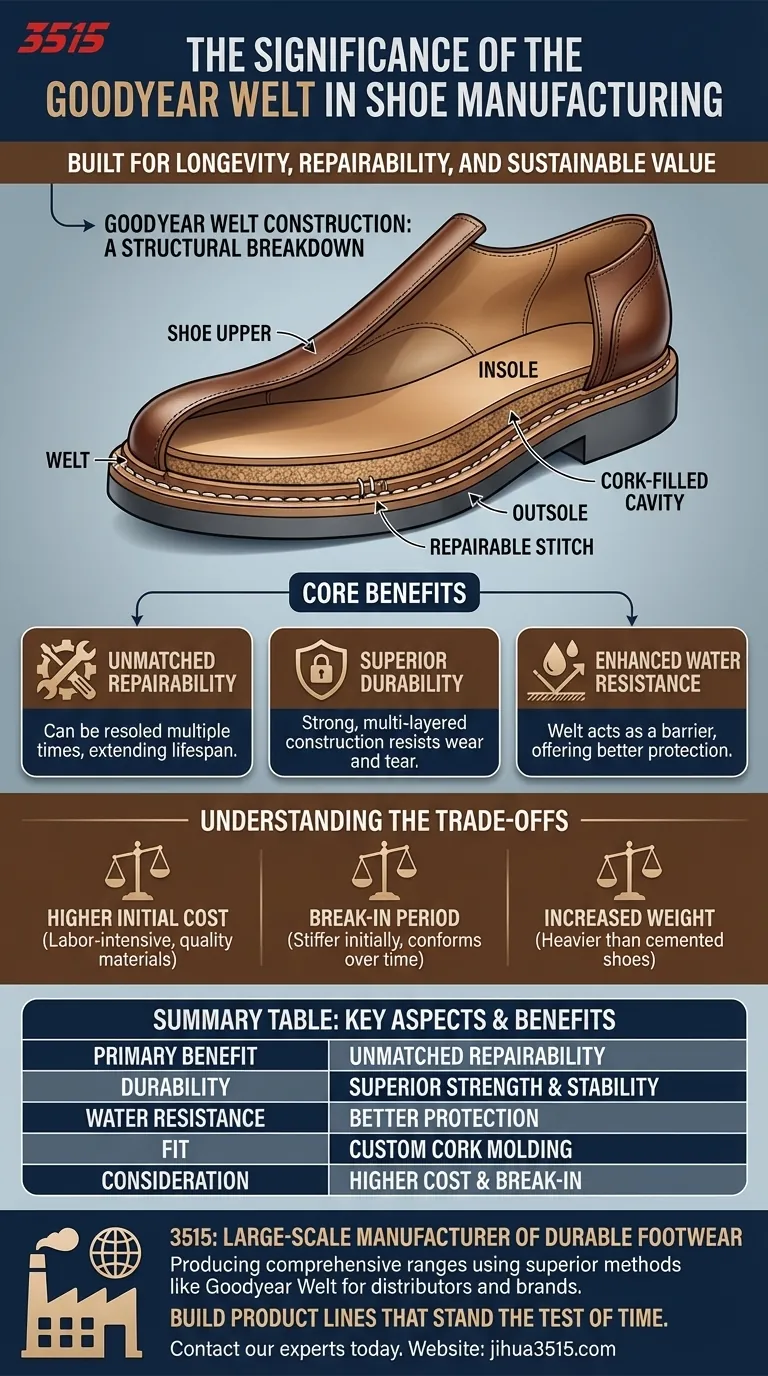

How a Goodyear Welt Works: A Structural Breakdown

To appreciate its significance, you must understand the construction. A Goodyear welt creates a secure and layered platform that separates your foot from the ground and the shoe's sole from its upper.

The Role of the Welt

The welt is a durable strip of leather that is stitched around the perimeter of the shoe. It acts as a crucial intermediary, serving as the connection point between the upper part of the shoe and the outsole you walk on.

Creating the Foundation

The process begins by shaping the shoe's upper over a form called a last. The welt is then lockstitched to both the upper and a canvas "rib" on the insole. This step creates a strong, unified foundation for the rest of the shoe.

The Cork-Filled Cavity

This stitching process forms a small cavity between the insole and the outsole. This space is filled with a layer of granulated cork. The cork provides cushioning, insulation, and, over time, molds to the unique shape of your foot, creating a custom-like fit.

Attaching the Outsole

Finally, the outsole is attached to the welt using a separate, heavy-duty stitch. This is the most critical step for repairability. Because the outsole is only stitched to the welt, a cobbler can easily remove and replace it without disturbing the shoe's upper or insole.

The Core Benefits of This Construction

The labor-intensive nature of the Goodyear welt delivers distinct advantages that are difficult to replicate with simpler, more common methods like adhesive cementing.

Unmatched Repairability

This is the primary benefit. The ability to resole the shoe multiple times significantly extends its life. When the sole wears out, it can be detached and replaced, giving the shoe a new lease on life while preserving the broken-in comfort of the upper.

Superior Durability

The overlapping layers and dual-stitching process create an exceptionally strong and stable shoe. This construction resists the twisting and flexing that can cause cemented shoes to delaminate or fall apart over time.

Enhanced Water Resistance

The welt acts as a barrier, minimizing the chance of water penetrating the shoe from the ground up. While not fully waterproof, it provides a much higher level of protection against the elements than most other construction methods.

Understanding the Trade-offs

No construction method is perfect for every situation. The objectivity of a technical advisor requires acknowledging the downsides.

The Higher Initial Cost

Goodyear welted shoes are more expensive. The process is labor-intensive, requires skilled artisans, and uses higher-quality materials, all of which contribute to a higher upfront price tag.

The Break-in Period

The robust, multi-layered construction often results in a stiffer shoe out of the box. It requires a break-in period for the leather and cork footbed to soften and conform to your foot, which some may find uncomfortable initially.

Increased Weight and Bulk

Compared to a lightweight, cemented sneaker, a Goodyear welted shoe is typically heavier and less flexible. The additional layers of leather, cork, and stitching add to its overall weight and profile.

Making the Right Choice for Your Goal

Selecting a shoe with this construction depends entirely on your priorities and what you value in footwear.

- If your primary focus is long-term value and durability: A Goodyear welt is the superior choice, as its repairability turns a high initial cost into a sound investment over decades.

- If your primary focus is sustainability: The ability to resole a shoe rather than discarding it makes Goodyear welting an environmentally conscious decision.

- If your primary focus is immediate comfort and a low budget: A cemented construction may be more practical for short-term needs, but it lacks the longevity and repairability of a welted shoe.

Ultimately, choosing a Goodyear welted shoe is a decision to prioritize enduring craftsmanship and a lifetime of service over initial convenience.

Summary Table:

| Aspect | Significance of Goodyear Welt |

|---|---|

| Primary Benefit | Unmatched repairability; shoes can be resoled multiple times. |

| Durability | Superior strength and stability from layered, stitched construction. |

| Water Resistance | Welt acts as a barrier, offering better protection than cemented shoes. |

| Fit | Cork layer molds to the wearer's foot for a custom-like fit over time. |

| Consideration | Higher initial cost and a break-in period are required. |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear using superior construction methods like the Goodyear welt for distributors, brand owners, and bulk clients.

Our production capabilities encompass all types of durable shoes and boots designed for longevity and customer satisfaction. Let us help you build a product line that stands the test of time.

Contact our experts today to discuss your manufacturing needs and discover the 3515 advantage.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- What makes rubber sole shoes an economical and practical choice? Unmatched Durability & All-Weather Value

- What are the disadvantages of leather shoe soles? Key Limitations in Traction & Durability

- Why should we wear rubber soled shoes? Unlock Superior Safety and Durability

- What makes natural rubber provide excellent traction and grip? Unlocking Superior Performance with Molecular Science

- What is vulcanized rubber and why is it used in products? The Key to Durable, Flexible Footwear