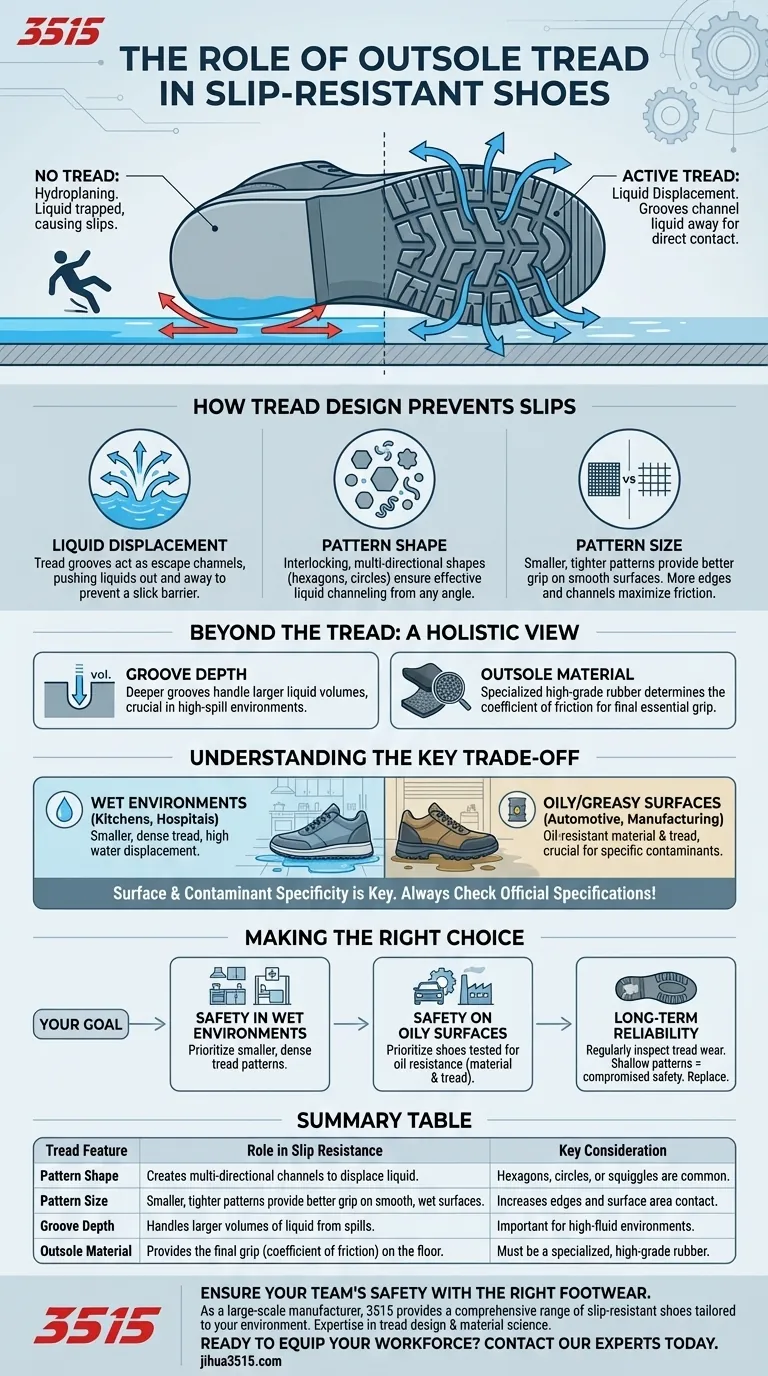

The primary role of the outsole tread in a slip-resistant shoe is not just to grip the floor, but to actively channel liquids out from underneath the sole. The specific shape and size of the tread pattern create a system of grooves that displaces contaminants like water or oil, preventing a slick barrier from forming between your shoe and the walking surface. This allows the sole material to make direct, solid contact with the floor.

The effectiveness of a slip-resistant shoe doesn't come from a simple "sticky" grip. It comes from the tread's sophisticated design, which functions like the treads on a car tire to prevent hydroplaning on slick surfaces.

How Tread Design Prevents Slips

Understanding the mechanics of the tread reveals why certain shoes are safer than others in specific environments. It's a system where pattern, size, and material work in concert.

The Principle of Liquid Displacement

The fundamental job of the tread pattern is to move liquid. When you step on a wet or oily floor, the pressure of your weight would otherwise trap a thin layer of liquid under the sole, causing you to slip.

The grooves in the tread act as escape channels. They push the liquid out and away from the center of the shoe, allowing the flat parts of the sole to make secure contact with the ground.

The Role of Pattern Shape

You will commonly see tread patterns using shapes like hexagons, circles, or intricate squiggles.

The specific shape is less important than its function: to create an interlocking, multi-directional network for channeling away fluid no matter the angle of the shoe. These patterns prevent liquid from getting trapped under any single point.

The Importance of Pattern Size

In general, smaller, tighter tread patterns provide better slip resistance on smooth, wet surfaces.

A higher density of smaller patterns creates more edges to bite into the floor and more channels to disperse liquid over a given area. This maximizes both friction and surface area contact.

Beyond the Tread Pattern: A Holistic View

While the tread pattern is critical, it is only one component of a truly effective slip-resistant shoe. Two other design features are equally essential.

Groove Depth

Deeper grooves can handle a greater volume of liquid. This is especially important in environments where spills are common or a significant amount of fluid is present on the floor.

Outsole Material

The material of the sole, typically a specialized high-grade rubber, determines the shoe's coefficient of friction. The tread pattern can clear a path, but it's the material itself that provides the final, essential grip on the floor surface.

Understanding the Key Trade-off

A shoe's design is always a balance of features. What works perfectly in one environment may be inadequate in another.

Surface and Contaminant Specificity

The biggest pitfall is assuming all slip-resistant shoes are the same. A tread pattern highly effective against water might perform poorly on greasy or oily floors.

Always check the shoe's official specifications. Manufacturers test and rate their footwear for performance against specific contaminants. Your choice must match the unique conditions of your workplace.

Making the Right Choice for Your Goal

Select your footwear based on a clear understanding of your work environment, not just a generic "slip-resistant" label.

- If your primary focus is safety in wet environments (e.g., commercial kitchens, hospitals): Look for shoes with smaller, dense tread patterns designed for maximum water displacement.

- If your primary focus is working on oily or greasy surfaces (e.g., automotive shops, manufacturing floors): Prioritize shoes explicitly tested and rated for oil resistance, as the sole's material compound is just as crucial as its tread pattern.

- If your primary focus is long-term reliability: Regularly inspect your shoe's tread for wear. Once the patterns become shallow, their ability to displace liquid is severely compromised, and it is time for a replacement.

Ultimately, choosing the right shoe is an informed decision that directly contributes to your personal safety.

Summary Table:

| Tread Feature | Role in Slip Resistance | Key Consideration |

|---|---|---|

| Pattern Shape | Creates multi-directional channels to displace liquid. | Hexagons, circles, or squiggles are common. |

| Pattern Size | Smaller, tighter patterns provide better grip on smooth, wet surfaces. | Increases edges and surface area contact. |

| Groove Depth | Handles larger volumes of liquid from spills. | Important for high-fluid environments. |

| Outsole Material | Provides the final grip (coefficient of friction) on the floor. | Must be a specialized, high-grade rubber. |

Ensure your team's safety with the right footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our expertise in tread design and material science ensures superior performance against water, oil, and grease, tailored to your specific work environment—from commercial kitchens to industrial floors.

Ready to equip your workforce with reliable, safety-focused footwear? Contact our experts today to discuss your needs and discover our manufacturing capabilities.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- How can slip-resistant shoes help reduce workplace accidents? Prevent Slips & Falls with Engineered Safety Footwear

- How do non-slip shoes prevent falls, slips, and trips? The Science of Slip-Resistant Footwear

- How can footwear reduce slip, trip, and fall risks? Match Your Shoes to the Hazard

- What are the key features to look for in slip-resistant shoes? An Expert's Guide to Workplace Safety

- What are the benefits of using high-grip anti-slip work shoes for MBR tank maintenance? Ensure worker safety today!

- What roles do full-body harnesses and industrial walkers play in friction assessments? Safety Tools for Footwear Testing

- How can you combine style and comfort in workplace footwear? Master the Art of All-Day Support

- How can a hot glue gun be used to improve shoe traction? A Quick DIY Fix for Slippery Soles