Okay, so you want to know the specific requirement for front foot protection under EN ISO 20345. Let's get right to it: the standard mandates a 200 joule impact resistance for the toe area. That's the bedrock. But, as you know, it's just the beginning. The real key lies in understanding how this base protection interacts with the different 'S' classifications that define total safety footwear performance.

The Bottom Line: All shoes under EN ISO 20345 offer 200 joule toe protection. The real decision is in choosing the right 'S' rating (S1, S1P, S2, S3, S4, or S5) that matches your work's unique hazards.

Now, let's break this down further.

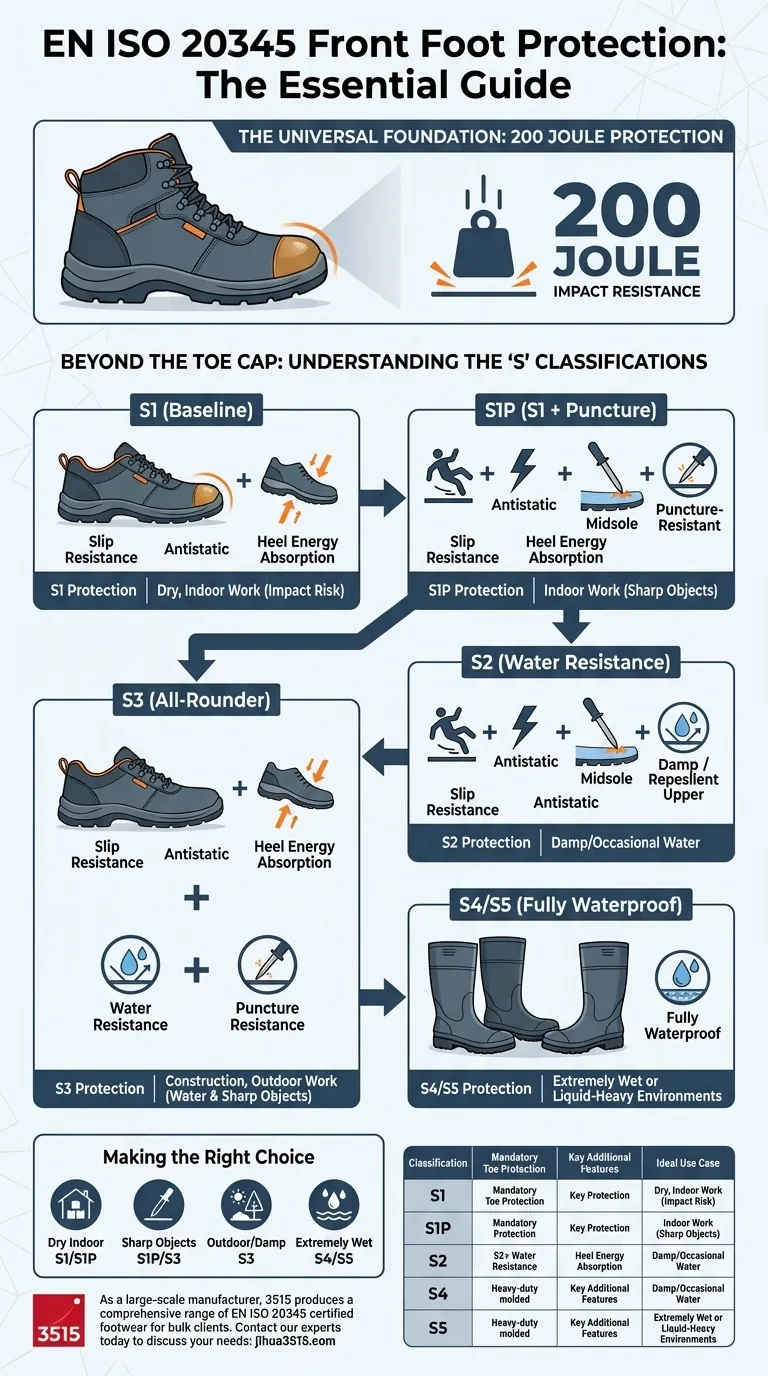

The Universal Foundation: 200 Joule Protection

The 200 joule impact resistance means the toe cap must withstand a specific impact force without compromising the wearer's foot. Think of it as the minimum barrier against dropped objects. This is a must-have for any shoe to be classified as safety footwear under this standard.

Beyond the Toe Cap: Understanding the 'S' Classifications

This is where things get interesting, and more relevant to your actual needs. The 'S' classifications build upon the 200-joule toe cap, adding layers of protection for different environments.

-

S1 Protection: This is the baseline, offering the 200-joule toe cap, slip resistance, antistatic properties, and energy absorption in the heel. Suitable for dry, indoor environments with impact risk.

-

S1P Protection: This is S1 plus a puncture-resistant midsole. This is a crucial addition for environments where sharp objects might be underfoot.

-

S2 Protection: This builds on S1 with a water-resistant upper. Great for environments that might be damp or exposed to occasional water splashes.

-

S3 Protection: This is the most common all-rounder. It combines the water resistance of S2 with the puncture resistance of S1P. Ideal for construction, general outdoor work, or anywhere with a moderate risk of water and sharp objects.

-

S4 and S5 Protection: These are the heavy-duty options, typically waterproof boots made from molded polymer/rubber. S4 offers the base toe protection, while S5 adds the puncture-resistant midsole. Perfect for extremely wet or liquid-prone environments.

Understanding the Trade-offs

Here's where experience comes in handy: more protection isn't always better.

-

More Isn't Always Better: An S5 boot might be overkill for an office setting. It could be heavier and less breathable. Choose the minimum level of protection needed for your environment.

-

"Water-Resistant" vs. "Waterproof": Remember, S2 and S3 offer water-resistant uppers, suitable for damp conditions. S4 and S5 are waterproof boots, designed for direct water exposure. This difference is key.

Making the Right Choice for Your Environment

Let's summarize with a clear action plan:

- Dry, indoor work with impact risk (e.g., logistics, light manufacturing): S1 or S1P is a solid choice.

- Work with risk of sharp objects on the ground (e.g., construction sites, warehouse): S1P or S3 is the way to go.

- Outdoor or damp conditions with impact and puncture risk (e.g., general construction, infrastructure): S3 is your best bet.

- Extremely wet environments or work with liquids (e.g., agriculture, concrete work): S4 or S5 are the protective boots for you.

By clearly understanding the 'S' classifications, you can choose the safety footwear that matches your job's unique risks, keeping you safe and comfortable. To be certified under EN ISO 20345, all safety footwear must provide front foot (toe) protection capable of withstanding a 200-joule impact. This is the universal, non-negotiable baseline requirement for any shoe or boot to carry the "safety" designation under this international standard.

The core principle of EN ISO 20345 is that while 200-joule toe protection is the mandatory foundation, the true measure of a shoe's suitability comes from understanding the additional protective features defined by its specific "S" classification.

The Universal Foundation: 200 Joule Protection

What This Standard Means

The 200-joule impact rating is the fundamental safety feature of any footwear certified to EN ISO 20345. It ensures the toe cap can absorb a significant level of energy, equivalent to a heavy object falling from a height, before it compromises the safety of the wearer.

The Starting Point for All Safety Shoes

This requirement applies to every classification, from the basic S1 to the most comprehensive S5. If a shoe does not meet this 200-joule standard, it cannot be classified as safety footwear under this norm.

Beyond the Toe Cap: Understanding the 'S' Classifications

While toe protection is universal, different work environments present unique hazards. The "S" ratings provide a clear system for identifying footwear that offers protection beyond the basic impact standard.

The Baseline: S1 Protection

An S1 rated shoe includes the 200-joule toe cap, slip-resistant soles, antistatic properties, and energy absorption in the heel. It is best suited for dry, indoor environments where there is a risk of impact but not from sharp objects on the ground.

Adding Puncture Resistance: S1P

The S1P classification includes all the features of S1 but adds a penetration-resistant midsole. This is a critical feature for environments where stepping on nails, screws, or other sharp debris is a risk.

Introducing Water Resistance: S2

An S2 shoe builds on the S1 standard by adding a water-resistant upper. This makes it suitable for work in damp conditions or outdoors where exposure to moisture is likely, but it does not include puncture protection.

The All-Rounder: S3

S3 is a highly common and comprehensive rating. It combines all the features of an S2 shoe (including water resistance) with the puncture-resistant midsole found in S1P footwear, offering robust protection for many construction and industrial jobs.

For Fully Wet Environments: S4 and S5

S4 and S5 ratings are typically for boots made from a rubber or moulded polymer, making them fully waterproof. An S4 boot has the 200-joule toe cap and is leak-proof. An S5 boot provides the highest level of protection, adding midsole penetration resistance to the waterproof S4 design.

Understanding the Trade-offs

Choosing the right safety footwear is about matching the protection to the specific hazards of your work, not simply picking the highest number.

More Protection Isn't Always Better

Selecting an S5 boot for a dry, indoor warehouse job is unnecessary. The added weight and reduced breathability of a fully waterproof, puncture-resistant boot can lead to discomfort without providing any relevant safety benefit for that environment.

"Water-Resistant" vs. "Waterproof"

It is crucial to understand the distinction between these terms. The uppers of S2 and S3 footwear are water-resistant, meaning they can handle damp conditions and light rain. In contrast, S4 and S5 boots are fully waterproof and designed for submersion or constant exposure to significant amounts of liquid.

Making the Right Choice for Your Environment

Your selection should be guided by a clear assessment of your daily workplace risks.

- If your primary focus is dry, indoor work with impact risk: An S1 shoe provides the necessary toe protection, while an S1P adds protection from sharp objects on the floor.

- If your primary focus is general outdoor work with mixed hazards: An S3 shoe offers a comprehensive solution with toe, puncture, and water resistance for versatile protection.

- If your primary focus is working in consistently wet or muddy conditions: An S4 boot is your waterproof solution, and an S5 adds critical puncture resistance for hazardous terrain.

Ultimately, understanding these classifications empowers you to select footwear that provides targeted protection for your specific environment.

Summary Table:

| Classification | Mandatory Toe Protection | Key Additional Features | Ideal Use Case |

|---|---|---|---|

| S1 | 200 Joule | Slip-resistant, antistatic, heel energy absorption | Dry, indoor environments |

| S1P | 200 Joule | S1 features + Penetration-resistant midsole | Indoor work with sharp object risk |

| S2 | 200 Joule | S1 features + Water-resistant upper | Damp or occasional wet conditions |

| S3 | 200 Joule | S2 features + Penetration-resistant midsole | Outdoor construction, general industry |

| S4 / S5 | 200 Joule | Fully waterproof (leak-proof) upper | Extremely wet or liquid-heavy environments |

Ensure Your Team is Fully Protected with the Right Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, from basic S1 models to heavy-duty S5 waterproof boots.

We can help you select or manufacture the perfect safety footwear that meets your specific hazard requirements and market demands.

Contact our experts today to discuss your needs: Get a Custom Quote

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What types of workplaces are steel toe boots traditionally used in? Essential Foot Protection for Hazardous Jobs

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- How to choose the right work boot? Match Safety Features to Your Job's Hazards