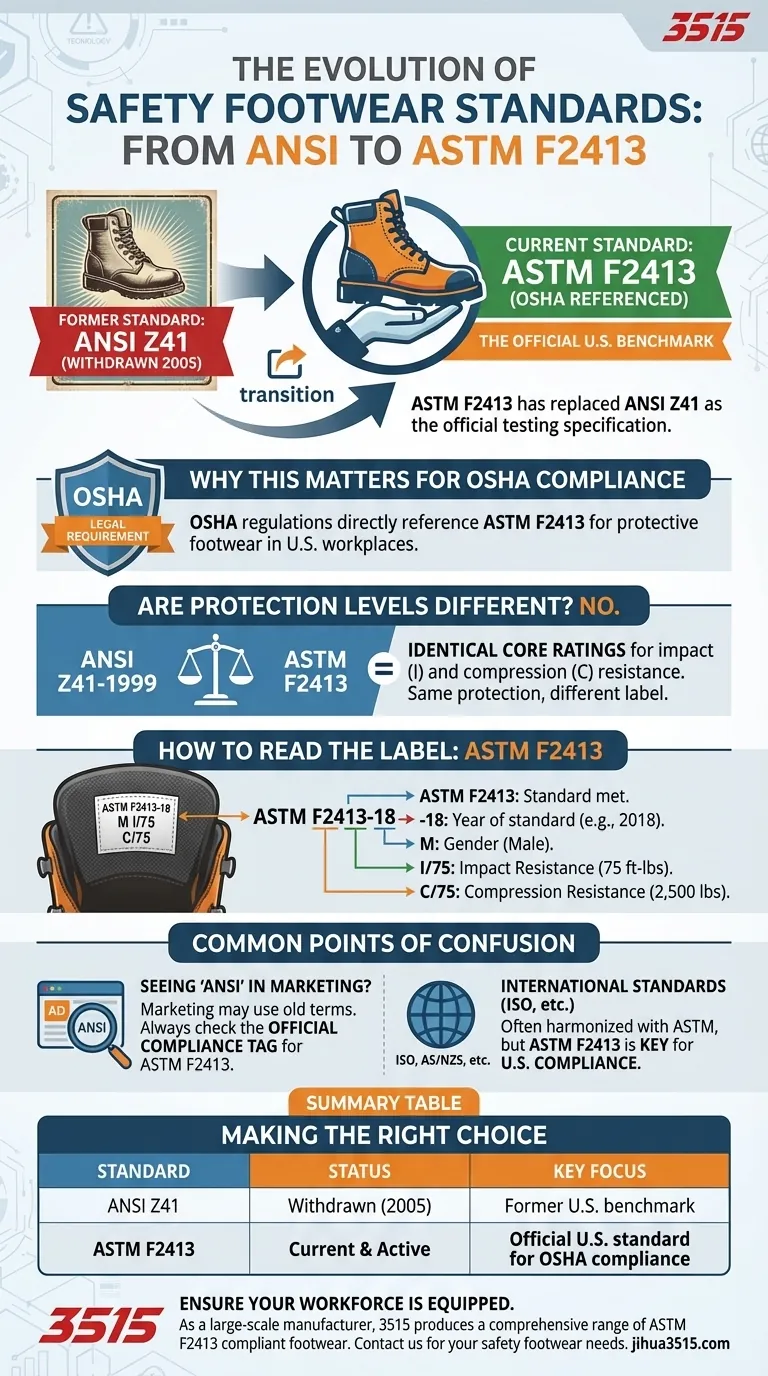

The short answer is that ASTM F2413 is the current standard which has replaced the older ANSI Z41 standard. While both organizations set safety footwear standards, the American National Standards Institute (ANSI) standard was withdrawn in 2005. The American Society for Testing and Materials (ASTM) now provides the official testing specifications referenced by OSHA for protective footwear in the United States.

For anyone purchasing new safety footwear, the key is to look for the ASTM F2413 label. This ensures your equipment meets the current, official standard for protection and regulatory compliance.

The Shift from ANSI to ASTM

To understand the relationship, it's helpful to see it as an evolution. For many years, ANSI was the primary source for safety footwear standards, but the responsibility has since shifted.

The Former Standard: ANSI Z41

For decades, the ANSI Z41 standard was the benchmark for protective footwear in the U.S. Many experienced professionals are still familiar with this designation from older equipment.

The Current Standard: ASTM F2413

In 2005, the ANSI Z41 standard was officially withdrawn. ASTM International took over the responsibility for developing and updating the specifications.

The new standard, ASTM F2413, now serves as the primary reference for performance requirements for protective footwear.

Why This Matters for OSHA Compliance

The Occupational Safety and Health Administration (OSHA) requires employers to ensure their workers use protective footwear when faced with certain hazards.

OSHA's regulations now directly reference ASTM F2413 as the consensus standard that compliant footwear must meet. This makes adherence to the ASTM standard a legal requirement in most applicable U.S. workplaces.

Are the Protection Levels Different?

A common source of confusion is whether the old ANSI standard offers less protection than the new ASTM standard. For the core safety ratings, the answer is no.

Identical Core Ratings

The fundamental tests for impact and compression resistance for the safety toe cap remain the same. The labeling system was carried over from ANSI to ASTM to ensure a smooth transition.

A boot rated under the old ANSI Z41-1999 standard provides the same level of toe protection as one rated under the current ASTM F2413 standard with the same markings.

How to Read the Label

The label, typically found on the inside of the tongue, provides a clear line of information. For example: ASTM F2413-18 M I/75 C/75

- ASTM F2413: Identifies the footwear meets the performance requirement.

- -18: Specifies the year of the standard it was tested against (in this case, 2018).

- M: Indicates the gender it is designed for (Male).

- I/75: Represents the impact resistance rating (75 foot-pounds).

- C/75: Represents the compression resistance rating (can withstand 2,500 pounds).

Common Points of Confusion

Even with a clear successor, the legacy of the old standard can create ambiguity.

Seeing "ANSI" on New Products

Some manufacturers may still mention ANSI in their marketing materials. This is often done to connect with customers who are familiar with the old terminology.

However, the official compliance tag inside the footwear must reference ASTM F2413. The marketing language is secondary to the official label.

Other International Standards

While ASTM is the key standard for the U.S., you may see others like ISO (International Organization for Standardization) or country-specific standards (AS/NZS, JIS, etc.).

These are often based on or harmonized with ASTM standards, but for U.S. workplace compliance, ASTM is the one that matters.

Making the Right Choice for Your Goal

- If your primary focus is OSHA compliance in the U.S.: Always look for a permanent tag inside the footwear specifying it meets ASTM F2413.

- If you're evaluating older, existing footwear: A boot marked with ANSI Z41-1999 offers equivalent toe protection, but all new purchases should meet the current ASTM standard.

- If you are confused by a product description: Ignore marketing language and always locate the official standards tag inside the boot to verify its ratings.

Focusing on the ASTM F2413 label is the most direct way to guarantee your footwear meets today's safety and compliance requirements.

Summary Table:

| Standard | Status | Key Focus |

|---|---|---|

| ANSI Z41 | Withdrawn (2005) | Former U.S. benchmark for protective footwear |

| ASTM F2413 | Current & Active | Official U.S. standard for OSHA compliance |

Ensure your workforce is equipped with compliant, high-quality safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413 compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get durable, certified protection tailored to your needs.

Contact us today to discuss your safety footwear requirements and benefit from our manufacturing expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management