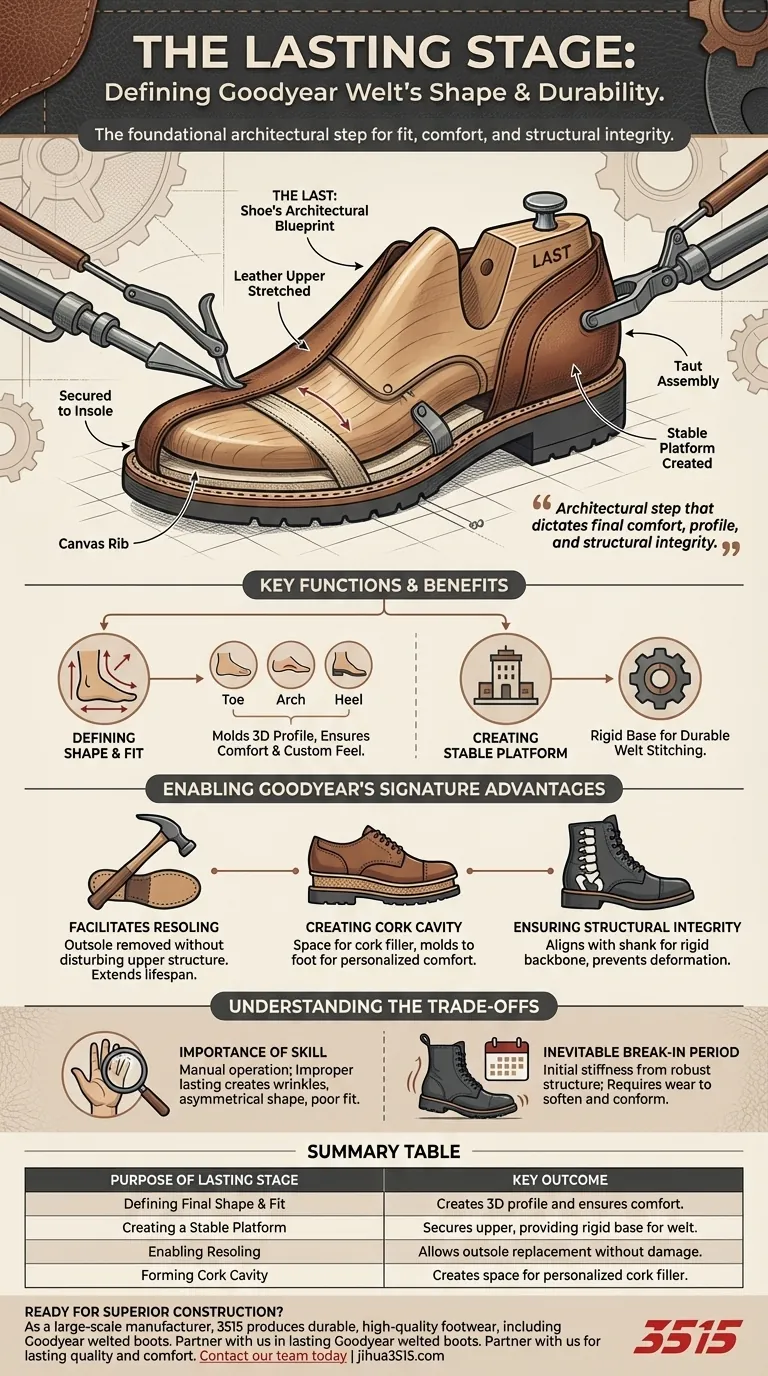

In Goodyear welt construction, the lasting stage is the foundational process that gives a shoe its definitive shape and fit. It involves meticulously stretching the leather upper over a foot-shaped mold, known as a "last," and temporarily securing it to the insole. This critical step ensures all components are perfectly aligned before the permanent welt stitching begins.

The purpose of lasting goes beyond mere shaping; it's the architectural step that dictates the final comfort, profile, and structural integrity of the shoe, creating the stable platform required for the durable Goodyear welt to be attached.

The Last: A Shoe's Architectural Blueprint

The entire lasting process revolves around the "last," a solid form that mimics the anatomy of a human foot. The choice of last determines everything from the shoe's size and width to its aesthetic character.

Defining the Final Shape and Fit

The primary function of lasting is to force the flat, two-dimensional leather upper to take on the three-dimensional shape of the last. This process sets the toe shape, the arch support, and the heel contour.

A well-executed lasting stage is the difference between a shoe that feels custom-molded and one that causes discomfort. The tension and positioning of the upper are locked in during this phase.

Creating a Stable Platform for Construction

During lasting, the edges of the upper are pulled down tightly and secured to the insole, often to a canvas rib that has been cemented to the insole's perimeter.

This creates a taut, stable assembly. It ensures the upper will not shift or warp during the subsequent, high-tension stitching process that attaches the welt. Without proper lasting, the entire shoe's structure would be compromised.

How Lasting Enables Goodyear Welt's Key Benefits

The lasting stage isn't just a preliminary step; it is what makes the signature advantages of a Goodyear welt possible.

Facilitating Resoling

By shaping the upper and securing it to the insole first, the lasting stage allows the outsole to be attached indirectly via the welt.

This means the outsole can be removed and replaced multiple times by a cobbler without ever disturbing the main structure or the carefully shaped upper, dramatically extending the shoe's lifespan.

Creating the Cavity for Cork

Once the upper is lasted and the welt is stitched on, a distinct cavity is formed between the insole and the outsole.

This space is filled with a compound, typically cork, which provides cushioning and breathability. Over time, this cork filling molds to the wearer's foot, creating a personalized and increasingly comfortable footbed.

Ensuring Structural Integrity

Lasting aligns the upper with the insole and its integrated shank—a supportive metal or wooden strip. This creates a rigid, supportive backbone for the shoe.

This robust internal structure, established during lasting, prevents the shoe from deforming over time and provides essential support to the wearer's arch.

Understanding the Trade-offs

While essential for quality, the lasting process and the resulting construction have implications you should be aware of.

The Importance of Skill

Lasting is a highly skilled, often manual, operation. An improperly lasted shoe can have wrinkles in the leather, an asymmetrical shape, or a poor fit that can never be corrected. The quality of the final product is heavily dependent on the craftsperson's expertise at this stage.

The Inevitable Break-in Period

The same tautness and structural rigidity that make a lasted, Goodyear-welted shoe durable also contribute to its initial stiffness.

The firm leather upper, the supportive shank, and the uncompressed cork filling all require a period of wear to soften and conform to your foot.

How This Affects Your Footwear Choice

Understanding the role of lasting helps you make a more informed decision based on what you value in a shoe.

- If your primary focus is ultimate durability and repairability: The lasting stage is the non-negotiable first step in building a shoe that is meant to be rebuilt and last for years, if not decades.

- If your primary focus is a personalized fit that improves with age: Lasting creates the precise shape and internal cavity necessary for the cork footbed to mold perfectly to your unique footprint over time.

- If your primary focus is immediate, out-of-the-box flexibility: Be aware that the robust structure established during lasting often means a Goodyear-welted shoe will feel stiffer initially than shoes made with more flexible, cemented construction.

Ultimately, knowing that a shoe's character is set during the lasting stage allows you to appreciate that its enduring quality is shaped long before the final sole is ever attached.

Summary Table:

| Purpose of Lasting Stage | Key Outcome |

|---|---|

| Defining Final Shape & Fit | Creates the shoe's 3D profile and ensures comfort by molding the upper to the last. |

| Creating a Stable Platform | Secures the upper to the insole, providing a rigid base for the durable welt stitching. |

| Enabling Resoling | Allows the outsole to be replaced without damaging the upper, extending the shoe's lifespan. |

| Forming Cork Cavity | Creates a space for cork filler that molds to the wearer's foot for personalized comfort. |

Ready to experience superior footwear construction?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including those built with robust construction methods like Goodyear welting.

Partner with us to offer your customers footwear defined by lasting quality and comfort.

Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries