The primary purpose of an anti-slip sole is to significantly reduce the risk of workplace accidents by providing superior grip on slippery or contaminated surfaces. This specialized outsole is an engineered safety feature, designed with specific materials and tread patterns to increase friction and prevent the slips, trips, and falls that constitute a major cause of occupational injuries.

An anti-slip sole is more than just a piece of rubber; it is a scientifically designed safety system. Its effectiveness is not based on a single feature, but on the careful balance of material composition, tread pattern, and its certified performance against standardized tests.

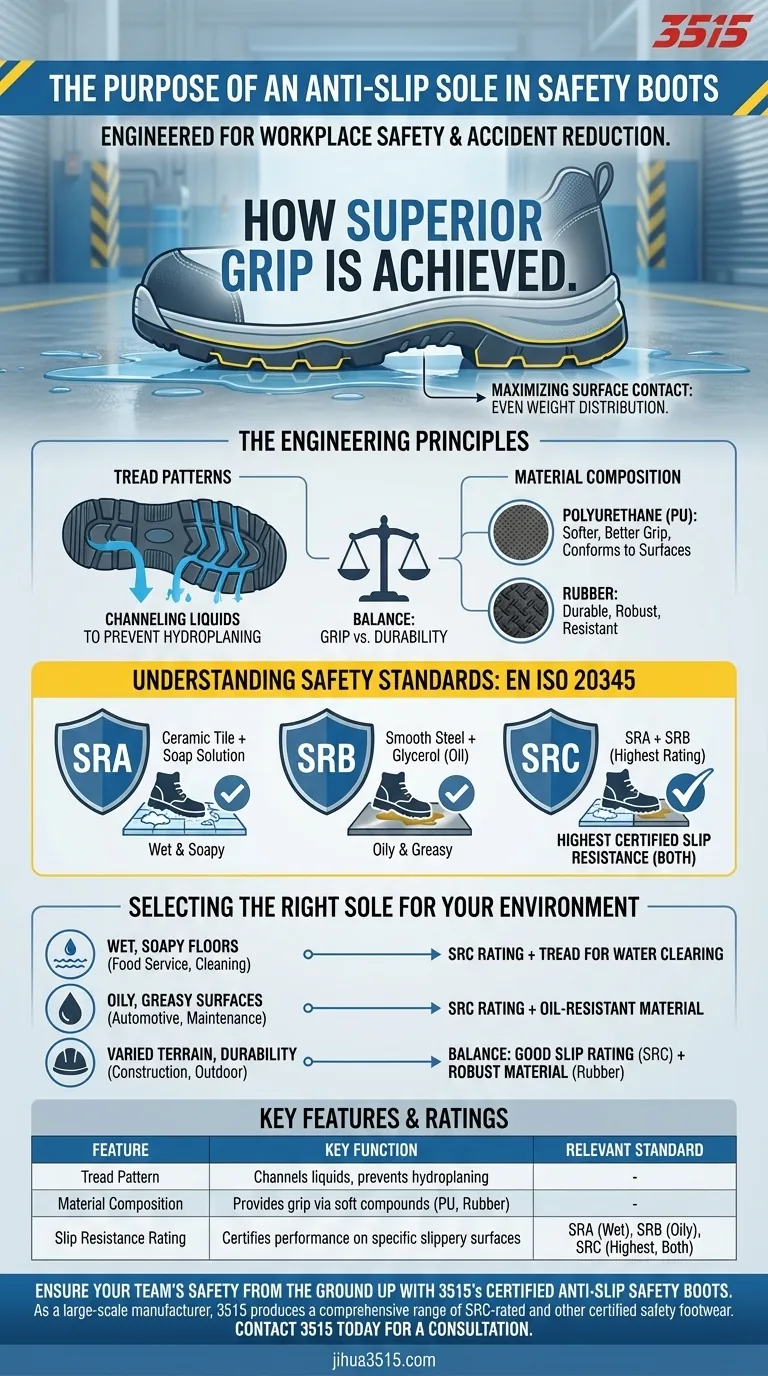

How Anti-Slip Soles Achieve Superior Grip

To understand the value of an anti-slip sole, you must look beyond the surface and see the engineering principles at work. The design is a deliberate combination of material science and physics.

The Role of Tread Patterns

The grooves and channels on the bottom of the boot are its tread pattern. These are not for decoration.

Their primary function is to channel liquids—such as water, oil, or soap—away from the point of contact between the sole and the floor. This prevents a film of liquid from forming, which would cause hydroplaning and a total loss of traction.

The Importance of Material Composition

The material of the sole itself is critical. Most safety boot soles are made from Polyurethane (PU) or Rubber.

Softer compounds tend to provide a better grip, as they can conform more closely to microscopic imperfections in a floor surface. However, this is often a trade-off, as softer materials may wear down more quickly.

Maximizing Surface Contact

The overall design of the sole aims to keep as much of the tread in contact with the ground as possible. A flat, stable profile ensures that body weight is distributed evenly, maximizing the force of friction that keeps you upright.

Understanding the Safety Standards

The term "anti-slip" is not just a marketing claim; it is a technical specification governed by strict regulations. For safety footwear in Europe and many other regions, this is defined by EN ISO 20345.

What the Ratings Mean

Under this standard, soles are tested in controlled laboratory conditions to determine their effectiveness. This results in one of three ratings.

- SRA: The sole has been tested and passed on a ceramic tile floor wetted with a dilute soap solution.

- SRB: The sole has been tested and passed on a smooth steel floor with glycerol (an oily liquid).

- SRC: The sole has passed both the SRA and SRB tests. This is the highest rating for slip resistance under the standard.

Understanding the Trade-offs

Choosing the right sole requires acknowledging that no single design is perfect for every situation. There are always engineering compromises to consider.

Grip vs. Durability

As mentioned, a softer sole compound that provides excellent grip may not be the most durable option for highly abrasive environments like a construction site. A harder, more durable compound might last longer but offer slightly less traction on smooth, wet surfaces.

Resistance to Other Hazards

The sole's material must often serve multiple purposes. It may also need to be resistant to oil, fuel, heat, or punctures. The formulation required to achieve heat resistance, for example, might have a different slip-resistance profile than one designed purely for grip in a kitchen.

Environmental Limitations

An SRC-rated boot provides outstanding protection, but it is not infallible. Extremely thick contaminants, large spills, or uniquely slick surfaces like ice can still overwhelm the sole's design. Anti-slip soles reduce risk; they do not eliminate it.

Making the Right Choice for Your Environment

To select the appropriate footwear, you must match the sole's capabilities to the specific hazards you face.

- If your primary focus is working on wet, soapy floors (e.g., food service, cleaning): An SRC rating is essential, with a tread pattern designed to clear water effectively.

- If your primary focus is on oily or greasy surfaces (e.g., automotive, industrial maintenance): Insist on an SRC rating and ensure the sole material is explicitly designated as oil-resistant.

- If your primary focus is durability on varied terrain (e.g., construction, outdoor work): Look for a balance between a good slip rating (SRC is always best) and a robust, hard-wearing sole material like rubber.

Ultimately, understanding the purpose and technology of an anti-slip sole empowers you to select the right tool for the job, ensuring your safety from the ground up.

Summary Table:

| Feature | Key Function | Relevant Standard/Rating |

|---|---|---|

| Tread Pattern | Channels liquids away to prevent hydroplaning | - |

| Material Composition | Provides grip via soft compounds (PU, Rubber) | - |

| Slip Resistance Rating | Certifies performance on specific slippery surfaces | SRA (Wet, Soapy), SRB (Oily), SRC (Highest, Both) |

Ensure your team's safety from the ground up with 3515's certified anti-slip safety boots.

As a large-scale manufacturer, 3515 produces a comprehensive range of SRC-rated and other certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered for superior grip and durability in your specific work environment.

Contact 3515 today for a consultation and discover how our footwear can reduce your workplace risks.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots