The primary downsides of Goodyear welt construction are its higher cost, a stiffer feel out of the box, and a slightly bulkier silhouette compared to other methods. These are not flaws in the construction but rather inherent trade-offs for its signature durability and repairability.

While often cited as disadvantages, the cost and initial stiffness of a Goodyear welted shoe are direct results of the very features that give it superior longevity, water resistance, and long-term, personalized comfort.

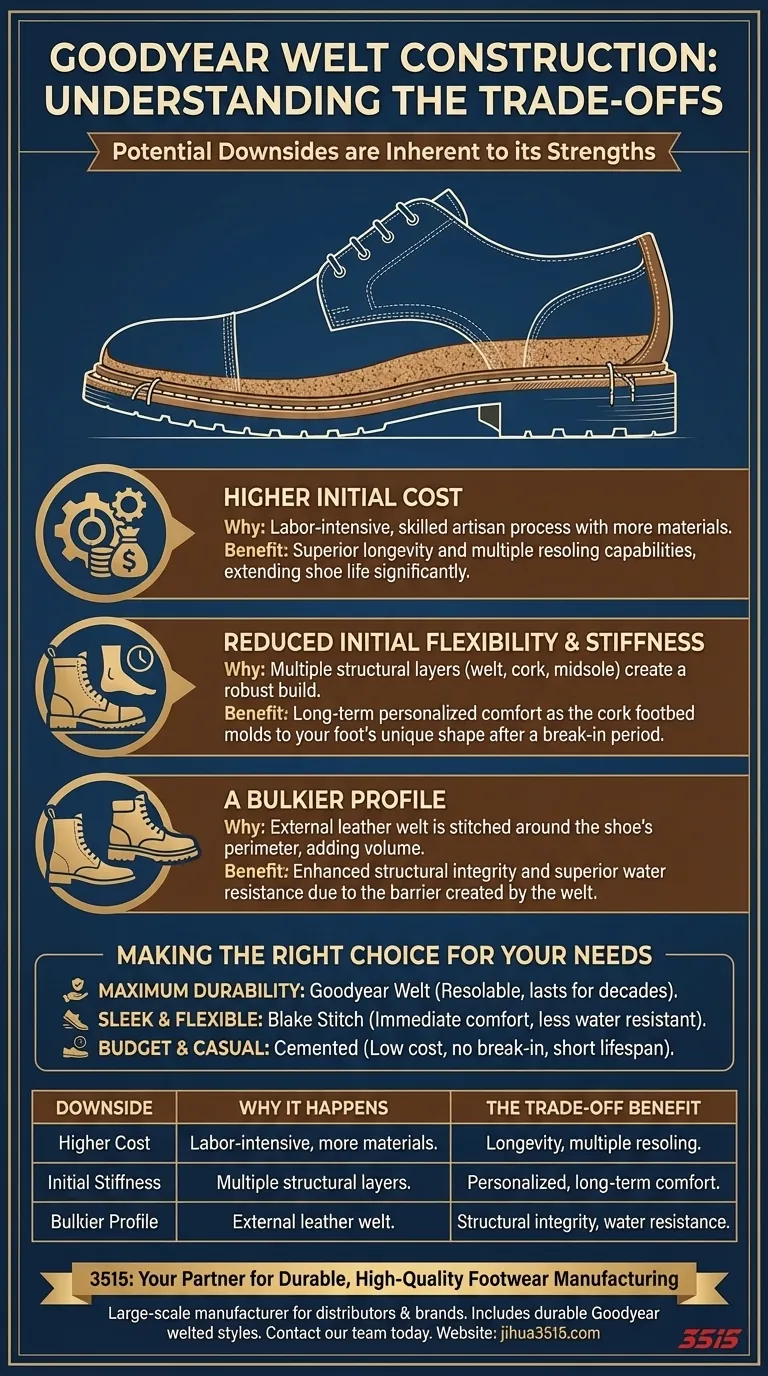

The Core Trade-offs of Goodyear Welt Construction

A Goodyear welt is an intricate, labor-intensive process. Understanding its "downsides" requires seeing them as the flip side of its greatest strengths.

Higher Initial Cost

The construction process is complex, time-consuming, and cannot be easily automated.

It demands significant hands-on work from highly skilled artisans. More materials are also used, including the leather welt, a cork filling, and often a separate midsole, all contributing to a higher price point.

Reduced Initial Flexibility

Goodyear welted shoes have several structural layers between your foot and the outsole. This robust construction makes the shoe feel rigid and firm when new.

This initial stiffness is a well-known characteristic and requires a "break-in" period as the leather and cork footbed mold to your foot's unique shape. Methods like the Blake stitch, which has fewer layers, feel more flexible from the first wear.

A Bulkier Profile

The welt itself is a strip of leather stitched around the perimeter of the shoe, connecting the upper to the outsole.

This external stitch adds volume to the shoe's edge, resulting in a wider, more substantial appearance. This is a defining aesthetic feature but is less sleek than construction methods that attach the sole more directly.

Why These "Downsides" Are Often Accepted

For those who invest in Goodyear welted footwear, the initial trade-offs are justified by significant long-term advantages.

Unmatched Longevity and Repairability

The primary benefit is that the sole can be replaced multiple times without disturbing the shoe's upper.

When the outsole wears out, a cobbler can simply cut the stitches holding it to the welt and attach a new one. This fundamentally extends the life of the shoe far beyond that of a cemented or Blake-stitched alternative.

Superior Water Resistance

The welt creates a robust barrier between the insole and the outsole. Because the stitching does not pass directly into the interior of the shoe, it is significantly more difficult for water to seep in from the ground.

Long-Term Personalized Comfort

Between the insole and midsole lies a layer of cork compound. Over time, your body heat and the pressure of your foot compress this cork, creating a custom-fit footbed.

While stiff at first, this molding process results in exceptional support and comfort that is unique to your foot.

Making the Right Choice for Your Needs

Choosing the right shoe construction depends entirely on your priorities.

- If your primary focus is maximum durability and longevity: The Goodyear welt is the undisputed choice, as its repairability allows a quality pair of shoes to last for decades.

- If your primary focus is a sleek, close-cut silhouette and immediate flexibility: A Blake-stitched shoe will better serve your needs, though with a trade-off in water resistance and ease of resoling.

- If your primary focus is budget and casual wear: A cemented construction offers the lowest cost and requires no break-in period, but the shoes cannot be resoled and have a much shorter lifespan.

Ultimately, understanding the Goodyear welt is about recognizing that its perceived disadvantages are inseparable from its strengths.

Summary Table:

| Downside | Why It Happens | The Trade-off Benefit |

|---|---|---|

| Higher Cost | Labor-intensive, skilled artisan process with more materials. | Superior longevity and multiple resoling capabilities. |

| Initial Stiffness | Multiple structural layers (welt, cork, midsole) for support. | Long-term personalized comfort as the footbed molds to your foot. |

| Bulkier Profile | External leather welt stitched around the shoe's perimeter. | Enhanced structural integrity and superior water resistance. |

Need a reliable supply of durable, high-quality footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable Goodyear welted styles built for longevity.

Partner with us to provide your customers with footwear that lasts. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes

- What are the benefits of breathable mesh in shoe design? Enhance Comfort and Performance

- How do non-slip athletic shoes differ from regular athletic shoes? Discover the Grip Technology

- What are the features of cross training shoes? Master Versatile Performance for Your Workouts