At its core, the Goodyear Welt is a traditional and highly durable method of shoe construction where a strip of leather, known as the "welt," is used to stitch the shoe's upper to its sole. This technique, patented by Charles Goodyear Jr. in 1871, creates an incredibly robust and water-resistant shoe that can be resoled multiple times without damaging the main body of the footwear.

The critical insight is that a Goodyear Welt creates a clear separation between the upper and the outsole. This intermediate layer—the welt—acts as a structural bridge, allowing for easy replacement of the sole while preserving the integrity of the shoe's upper for years, or even decades, of use.

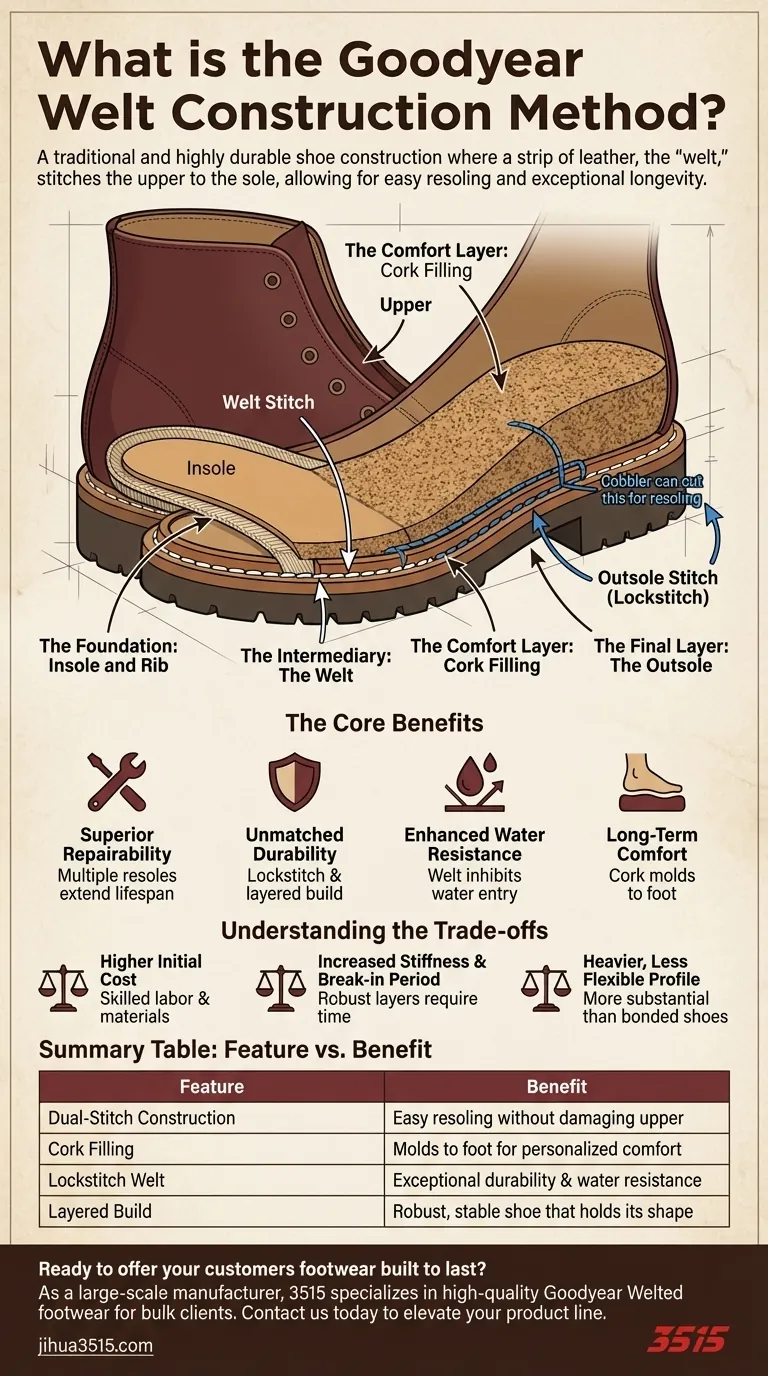

Deconstructing the Goodyear Welt

To understand why this method is so highly regarded, it's essential to visualize its layered construction from the inside out. It's an architecture, not just a simple stitch.

The Foundation: Insole and Rib

The process begins with the shoe's insole, which is the layer your foot rests on. A canvas or leather "rib" is cemented to the perimeter of this insole, creating a vertical lip that serves as the primary anchor point.

The Intermediary: The Welt

A specially prepared strip of leather, the welt, is stitched through the shoe's upper and into the canvas rib on the insole. This crucial stitch unites the upper part of the shoe with its foundational layer.

The Comfort Layer: Cork Filling

The cavity created between the insole and the outsole, inside the welt, is filled with a layer of granulated cork. This material provides cushioning, insulation, and breathability, and over time it will mold to the unique shape of your foot.

The Final Layer: The Outsole

Finally, the outsole (the part that contacts the ground) is lockstitched directly to the welt. This second, separate line of stitching is what makes resoling so effective; a cobbler can simply cut these stitches, remove the old sole, and attach a new one without ever touching the stitch that holds the upper together.

The Core Benefits of This Construction

The complexity of the Goodyear Welt directly translates into tangible advantages for the wearer, justifying its reputation as a premium construction method.

Superior Repairability

This is the hallmark benefit. Because the outsole is stitched to the welt and not directly to the upper, a worn-out sole can be replaced repeatedly. This dramatically extends the functional lifespan of the footwear.

Unmatched Durability

The use of a lockstitch means that if one part of the stitching breaks, the entire seam will not unravel. The dual-stitching system and layered construction create an exceptionally strong and stable shoe that holds its shape.

Enhanced Water Resistance

The welt creates a more effective barrier between the ground and your foot. While not fully waterproof, it significantly inhibits water from seeping into the shoe where the upper meets the sole.

Long-Term Comfort

The cork footbed is a key feature. As you wear the shoe, the cork compresses and molds to the contours of your foot, creating a personalized and highly comfortable fit that improves with age.

Understanding the Trade-offs

No construction method is perfect for every application. Objectivity requires acknowledging the inherent compromises of a Goodyear Welt.

Higher Initial Cost

This is a time-consuming and labor-intensive process that requires highly skilled craftsmanship. The materials and expertise involved result in a significantly higher price tag compared to more common cemented constructions.

Increased Stiffness and Break-in Period

The multiple layers and robust stitching create a shoe that is initially quite stiff. Goodyear welted footwear almost always requires a break-in period for the leather and cork to soften and conform to your foot.

A Heavier, Less Flexible Profile

The extra materials—the welt, the cork, the additional stitching—add weight and reduce the overall flexibility of the shoe. They are inherently more substantial and less "sneaker-like" than their bonded counterparts.

Making the Right Choice for Your Goal

Deciding if Goodyear Welted footwear is right for you depends entirely on what you value most in a shoe or boot.

- If your primary focus is long-term value and durability: A Goodyear Welt is one of the best investments you can make, as the ability to resole the shoe spreads its cost over many years of use.

- If your primary focus is immediate comfort and a lower price: You may be better served by a cemented or Blake-stitched shoe, which is typically more flexible out of the box and less expensive.

- If your primary focus is rugged performance for work or outdoor use: The durability and water resistance of a Goodyear Welt make it an industry standard for high-quality work and heritage boots.

Ultimately, choosing a Goodyear Welt is a commitment to quality craftsmanship and a product built to last.

Summary Table:

| Feature | Benefit |

|---|---|

| Dual-Stitch Construction | Allows for easy resoling without damaging the upper. |

| Cork Filling | Molds to your foot for personalized comfort over time. |

| Lockstitch Welt | Provides exceptional durability and water resistance. |

| Layered Build | Creates a robust, stable shoe that holds its shape for years. |

Ready to offer your customers footwear built to last?

As a large-scale manufacturer, 3515 specializes in producing high-quality Goodyear Welted footwear for distributors, brand owners, and bulk clients. Our extensive production capabilities ensure you receive durable, repairable shoes and boots that deliver exceptional long-term value.

Contact us today to discuss your manufacturing needs and elevate your product line with superior construction.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- What are the characteristics of canvas as a shoe material? A Guide to Lightweight, Breathable Footwear

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team

- What are the features of cross training shoes? Master Versatile Performance for Your Workouts

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes

- What are the benefits of breathable mesh in shoe design? Enhance Comfort and Performance