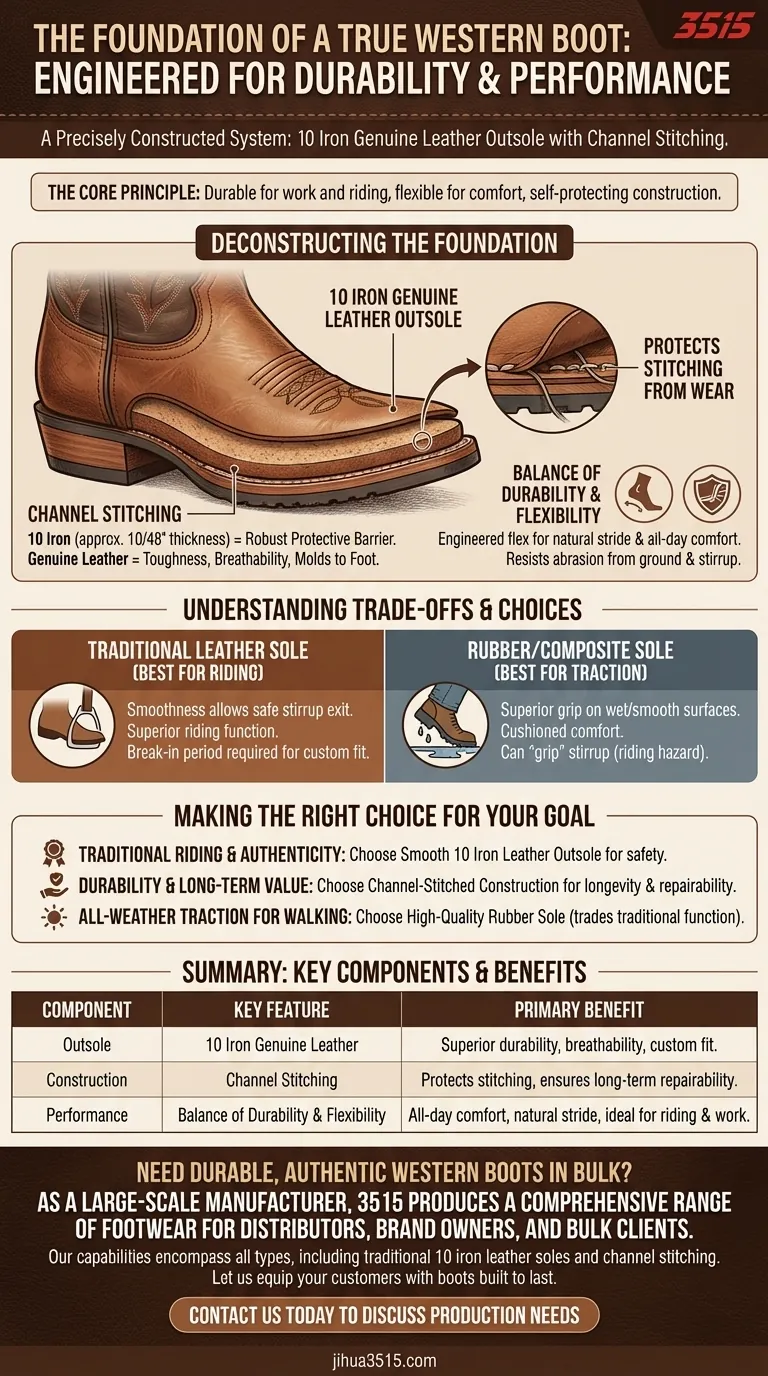

The foundation of a true western boot is a precisely constructed 10 iron genuine leather outsole secured with channel stitching. This specific combination is not arbitrary; it is an engineered system designed to provide a unique balance of rugged durability, essential flexibility, and long-term service life.

The core principle behind a western boot's foundation is creating a sole that is durable enough for the rigors of work and riding, yet flexible enough to be comfortable, all while protecting its own construction from wear and tear.

Deconstructing the Boot's Foundation

To understand why this foundation is so important, we must look at its individual components and how they work together. It's a system where each part serves a distinct and critical purpose.

The Role of the Leather Outsole

The outsole is the layer that makes direct contact with the ground and the stirrup. Using 10 iron genuine leather is a specific choice for its inherent properties.

"Iron" is a traditional unit of measurement for leather thickness, where one iron equals 1/48th of an inch. A 10 iron sole is therefore robust and substantial, providing a protective barrier.

Genuine leather offers a blend of toughness and breathability that synthetic materials struggle to replicate, molding to the wearer's foot over time.

The Balance of Durability and Flexibility

The thickness of the leather provides exceptional durability against abrasion from walking or the friction of a stirrup.

However, unlike a rigid plank, this leather foundation is engineered to have enough flexibility for a natural stride. This prevents the boot from feeling like a ski boot and is crucial for all-day comfort.

The Critical Detail: Channel Stitching

This is a hallmark of high-quality boot construction. A channel is cut into the leather outsole, and the sole is stitched to the rest of the boot from within that channel.

A leather flap is then sealed over the channel, hiding and protecting the stitching. This prevents the threads from being worn away by contact with the ground, which would cause the sole to detach prematurely.

Understanding the Trade-offs

While the traditional leather foundation is revered, it's essential to understand the context and potential downsides. This construction method represents a specific set of priorities.

Leather vs. Rubber Soles

Many modern boots now feature rubber or composite outsoles. These often provide superior grip on wet or smooth surfaces and may feel more cushioned from day one.

However, a traditional leather sole is superior for riding, as its smoothness allows the foot to slide easily and safely from a stirrup. Rubber can "grip" the stirrup, creating a potential hazard.

The Break-in Period

A 10 iron leather outsole is not instantly comfortable. It requires a break-in period where the thick, sturdy leather slowly molds to the unique shape and flex points of your foot.

This initial stiffness is the trade-off for achieving a truly custom fit and unparalleled long-term comfort.

Making the Right Choice for Your Goal

Understanding the boot's foundation empowers you to select footwear that truly meets your needs, whether they are for function, fashion, or longevity.

- If your primary focus is traditional riding and authenticity: A smooth, 10 iron leather outsole is non-negotiable for proper function and safety in the stirrup.

- If your primary focus is durability and long-term value: Seek out channel-stitched construction, as this is a clear indicator that the boot was built to last and be repaired, not just replaced.

- If your primary focus is all-weather traction for walking: You may consider a high-quality boot with a rubber sole, understanding you are trading traditional riding function for grip.

By recognizing these foundational elements, you can assess a boot's quality and purpose at a glance.

Summary Table:

| Component | Key Feature | Primary Benefit |

|---|---|---|

| Outsole | 10 Iron Genuine Leather | Superior durability and breathability, molds to the foot over time |

| Construction | Channel Stitching | Protects stitching from wear, ensures long-term repairability |

| Performance | Balance of Durability & Flexibility | All-day comfort and natural stride, ideal for riding and work |

Need durable, authentic western boots in bulk? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of western boots, including those with traditional 10 iron leather soles and channel stitching for maximum durability and value. Let us help you equip your customers with boots built to last. Contact us today to discuss your production needs!

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What role do specialized toe and heel lasting machines play? Key to Structural Integrity and Precision Fit

- Why is it necessary to accurately define the source of recycled materials in footwear? Ensuring Performance & Integrity

- What leather options are available for custom cowboy boots? Find the Perfect Material for Your Needs

- How do customized shoe insoles contribute to the research and development of gait assessment systems? Enhancing R&D Data

- Why is specialized foot analysis software used to divide footprints? Unlock Precise Data for Long-Duration Standing

- Why use a 1000 Hz sampling rate for smart insole signals? Capture High-Frequency Gait Data for Precision Safety

- How does performance infill in artificial turf systems affect footwear friction testing? Master Traction & Safety

- How are the toebox and heel padding damage evaluated? A 1-5 Scale Guide to Shoe Condition