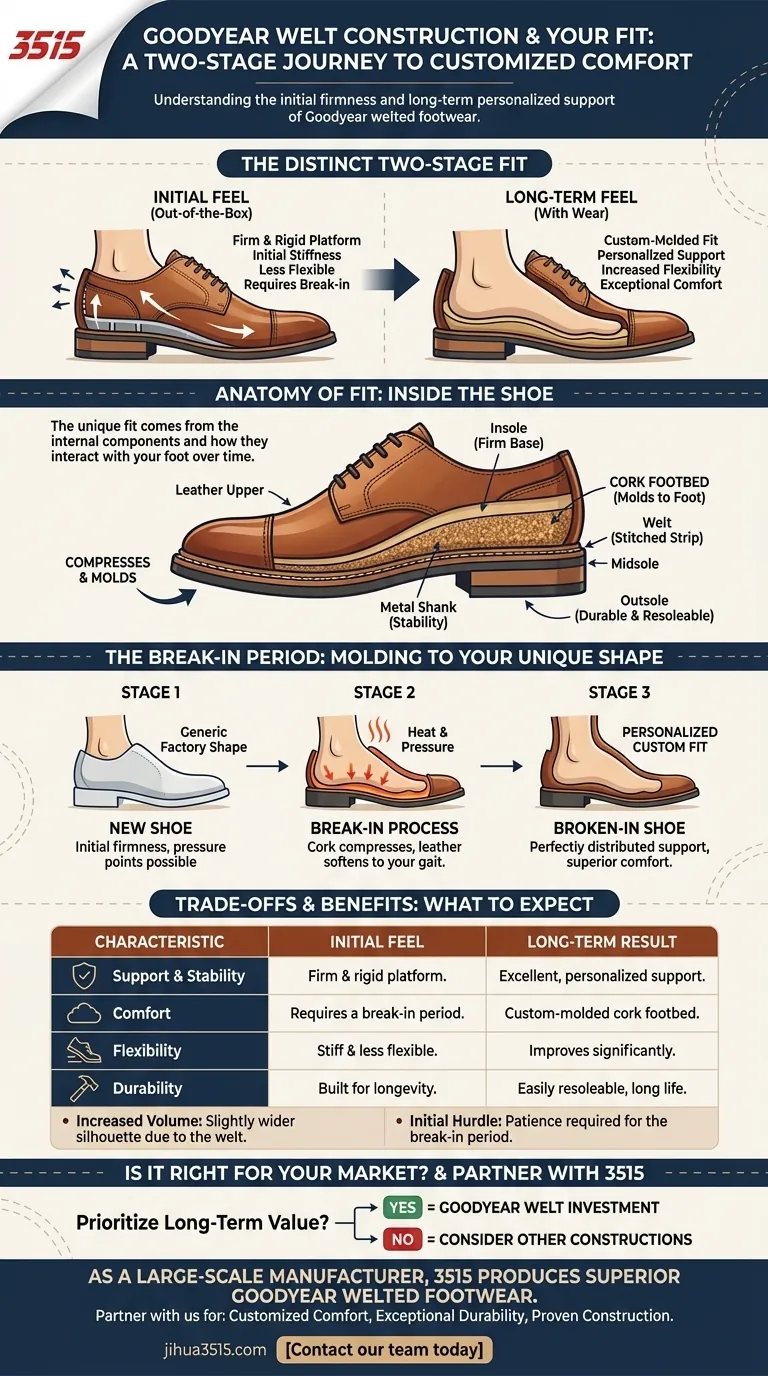

In short, a Goodyear welted shoe has a distinct two-stage fit. Initially, the construction feels noticeably firmer and more rigid than other shoes. However, with wear, a layer of cork filling between the insole and outsole compresses and molds to the unique shape of your foot, creating a truly customized and supportive fit over time.

The initial stiffness of a Goodyear welted shoe can be misleading. The construction's true benefit to fit is not its out-of-the-box feel, but its ability to create a personalized footbed through a break-in period, offering exceptional long-term comfort and support.

The Anatomy of Fit: What's Happening Inside the Shoe?

The unique fit of a Goodyear welted shoe is a direct result of its specific internal components and how they interact with your foot. It's an architecture designed for longevity, not instant gratification.

The Initial Firmness and Support

A new Goodyear welted shoe is built from multiple sturdy layers: an insole, a leather welt, a midsole, a metal shank, and the final outsole.

This layered construction, held together by robust stitching, creates a very stable and supportive platform. The initial feeling is one of rigidity, not plushness.

The Magic of the Cork Footbed

The defining feature for long-term fit is the cavity between the insole and outsole, which is filled with granulated cork.

Cork is a remarkable material that responds to the heat and pressure of your foot. As you walk, it gradually compresses and molds, creating a precise impression of your foot's unique contours.

The Break-in Period: From Firm to Custom

This molding process is what constitutes the "break-in" period. It’s the transition from a generic, factory-shaped shoe to one that is personally customized to your anatomy.

As the cork conforms and the quality leather upper softens to your gait, the shoe transforms. The initial firmness gives way to a feeling of perfectly distributed support that is difficult to replicate with other construction methods.

Understanding the Trade-offs

While the long-term benefits are significant, the Goodyear welt construction method involves compromises that are critical to understand before you invest.

Increased Volume and Profile

The welt—the strip of leather stitched around the shoe's perimeter—adds physical volume.

This results in a slightly wider, more substantial silhouette compared to sleeker constructions like a Blake stitch or a cemented sole. This is an aesthetic and physical characteristic of the design.

The Initial Comfort Hurdle

The break-in period is a feature, not a flaw, but it requires patience.

If you are seeking immediate, sneaker-like comfort right out of the box, the initial stiffness of a Goodyear welted shoe can be a significant hurdle.

Reduced Initial Flexibility

The same structural integrity that provides excellent support also results in less flexibility when the shoe is new.

The sole will feel stiff underfoot and will not bend as easily as a lighter shoe. This flexibility improves dramatically as the shoe breaks in.

Is a Goodyear Welted Shoe Right for You?

Choosing this construction depends entirely on prioritizing long-term value over initial feel.

- If your primary focus is long-term comfort and durability: The personalized fit from the molded cork footbed and the shoe's robust, resoleable nature make it an outstanding investment.

- If your primary focus is immediate, out-of-the-box comfort: You may find the initial stiffness challenging and should be prepared for a break-in period of several wears.

- If your primary focus is a sleek, low-profile silhouette: The inherent bulk of the welt may not align with your goal, and a Blake-stitched or cemented shoe might be a better choice.

Ultimately, appreciating a Goodyear welted shoe means understanding that you are investing in a fit that is earned over time.

Summary Table:

| Fit Characteristic | Initial Feel | Long-Term Result |

|---|---|---|

| Support & Stability | Firm and rigid platform | Excellent, personalized support |

| Comfort | Requires a break-in period | Custom-molded cork footbed for superior comfort |

| Flexibility | Stiff and less flexible | Improves significantly with wear |

| Durability | Built for longevity with robust materials | Easily resoleable, extending the shoe's life |

Ready to Experience Superior, Long-Lasting Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the superior Goodyear welt construction.

Partner with us to provide your customers with footwear that offers:

- Customized Comfort: Shoes that mold to the wearer's foot for unmatched long-term fit.

- Exceptional Durability: Built to last and easily resoleable, maximizing value.

- Proven Construction: Leverage our expertise in time-tested manufacturing techniques.

Contact our team today to discuss how we can manufacture the perfect footwear solutions for your market.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What causes white marks on rubber boots, and how can they be removed? A Guide to 'Blooming' & Boot Care

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained