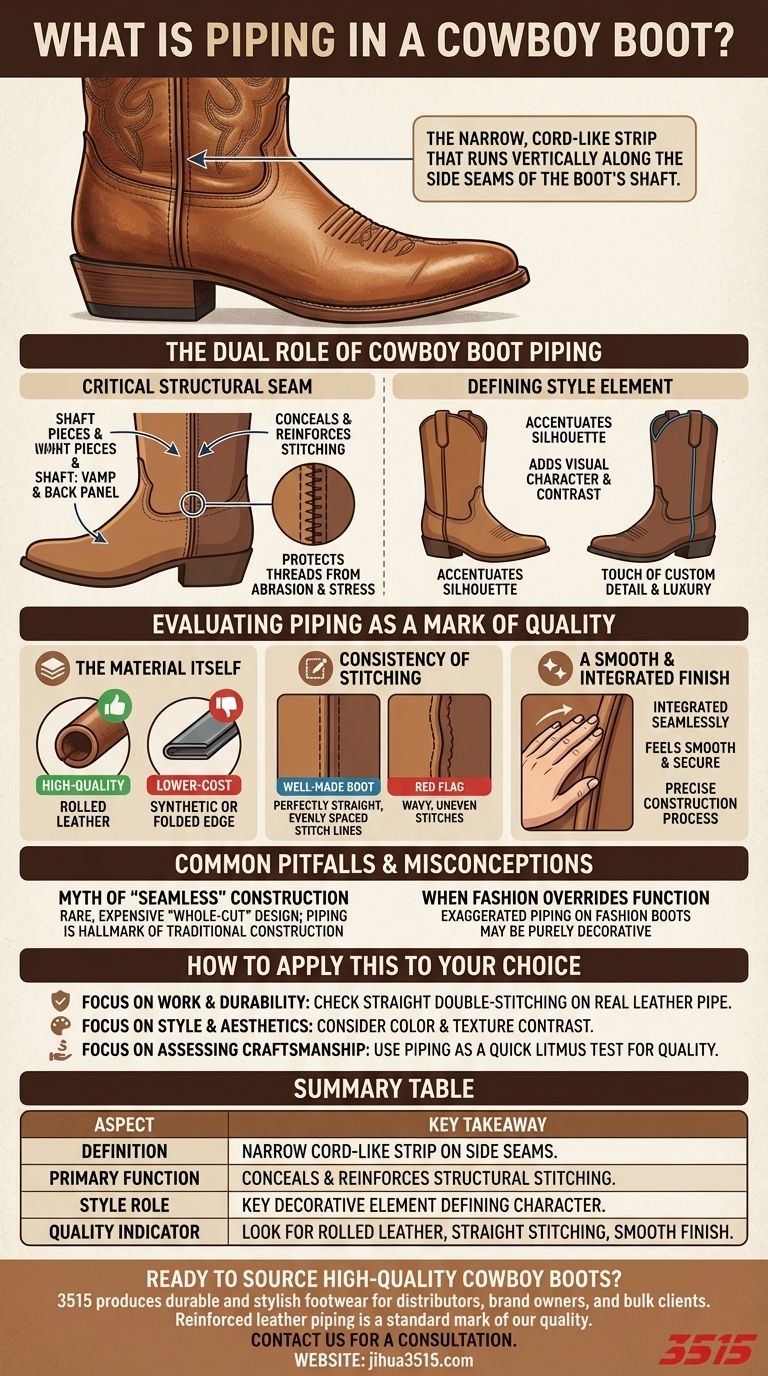

In cowboy boot terminology, piping refers to the narrow, cord-like strip that runs vertically along the side seams of the boot's shaft. It serves the critical dual purpose of concealing and reinforcing the stitching that joins the front and back pieces of the shaft, while also acting as a key decorative element.

Piping is not merely a decorative trim; it is a fundamental component of classic cowboy boot construction. Its execution—from the material used to the quality of the stitching—is often a direct indicator of the boot's overall craftsmanship and durability.

The Dual Role of Cowboy Boot Piping

Many people see the piping as just a stylistic flourish, but its primary role is deeply functional. Understanding both aspects allows you to better appreciate the design and construction of any boot.

A Critical Structural Seam

The shaft of most cowboy boots is constructed from two main pieces of leather: a front panel (the vamp and upper front) and a back panel.

The piping covers the side seam where these two pieces are stitched together. This protects the structural threads from abrasion and stress, significantly enhancing the long-term durability of the boot shaft.

A Defining Style Element

Function aside, piping is one of the most effective tools a bootmaker has for adding visual character.

By using a contrasting color, the piping can accentuate the boot's silhouette, drawing the eye upward. The choice of material—from matching leather to exotic skins—can also add a subtle touch of custom detail and luxury.

Evaluating Piping as a Mark of Quality

You can learn a lot about a boot's construction by examining the piping closely. It’s an easy-to-spot detail that often reveals the level of care invested in the manufacturing process.

The Material Itself

In high-quality boots, the piping is typically made from a thin piece of rolled leather, creating a sturdy and rounded profile. Lower-cost boots may use a synthetic material or simply a folded edge of the shaft's own leather, which offers less reinforcement.

Consistency of the Stitching

Look closely at the stitches running alongside the piping. On a well-made boot, the stitch lines will be perfectly straight, evenly spaced, and consistent from the top of the shaft down to the heel. Wavy lines or uneven stitches can be a red flag for rushed production.

A Smooth and Integrated Finish

The piping should be integrated seamlessly into the shaft. Run your fingers over it; it should feel smooth and secure, not rough or loose. This indicates a precise construction process where all components fit together perfectly.

Common Pitfalls and Misconceptions

Understanding the nuances of boot construction helps you avoid common mistakes when evaluating a pair.

The Myth of "Seamless" Construction

Occasionally, you might see a boot with no visible side seam or piping. This is often a "whole-cut" or single-piece shaft design. While elegant, this is a very difficult and expensive construction method, making it rare.

For the vast majority of boots, the presence of a well-executed side seam with piping is the hallmark of traditional, time-tested construction, not a flaw.

When Fashion Overrides Function

Some highly stylized fashion boots may use exaggerated or purely decorative piping that offers little structural reinforcement. Be aware that in such cases, the element is for looks only and may not contribute to the boot's durability.

How to Apply This to Your Choice

Your priorities will determine how you should evaluate a boot's piping.

- If your primary focus is work and durability: Pay close attention to the straightness of the double-stitching along a real leather pipe, as this seam is a critical stress point.

- If your primary focus is style and aesthetics: Consider how the piping's color and texture contrast with the shaft leather to enhance the boot's overall design.

- If your primary focus is assessing overall craftsmanship: Use the piping as a quick litmus test; a perfectly executed, smooth leather pipe is a strong signal of a high-quality boot.

By understanding this single, crucial detail, you gain a more discerning eye for the quality and character of any cowboy boot.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Definition | A narrow, cord-like strip on the boot shaft's side seams. |

| Primary Function | Conceals and reinforces the structural stitching for durability. |

| Style Role | A key decorative element that defines the boot's character. |

| Quality Indicator | Look for rolled leather, straight stitching, and a smooth finish. |

Ready to Source High-Quality Cowboy Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and stylish footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, where precise details like reinforced leather piping are a standard mark of our quality.

Let us help you build a boot collection that balances authentic craftsmanship with commercial appeal.

Contact us today for a consultation and to discuss your production needs.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How do safety briefings improve the consistent use of PPE? Driving Compliance and Safety Culture in the Workplace

- Why reference numerical prediction models for road slipperiness in footwear procurement? Optimize Safety with Data.

- What function does a 3D-printed custom socket serve in biomechanical experiments? Achieve Precision Load Transmission

- What should I consider when measuring my feet for shoe size? Get the Perfect Fit Every Time

- What is Aerogel insulation made from, and how does it work? Unlock the Secrets of the World's Best Insulator

- What is the functional purpose of multi-density EVA in diabetic insoles? Enhancing Support & Pressure Redistribution

- How does Cordura fabric perform in different weights and styles? Find the Right Balance of Durability & Flexibility

- What is the specific testing value of a 1.6 Hz sinusoidal disturbance? High-Precision Balance Analysis Revealed