In footwear, cement construction is a modern manufacturing method where a shoe's upper is attached directly to its outsole using a strong adhesive. This technique is prevalent in sneakers and many casual shoes because it is fast and cost-effective. However, this reliance on glue means the shoe is less durable and almost impossible to resole compared to traditionally stitched footwear.

Cement construction prioritizes manufacturing speed, flexibility, and a lower initial cost. This comes at a direct trade-off with long-term durability, water resistance, and the potential for repair.

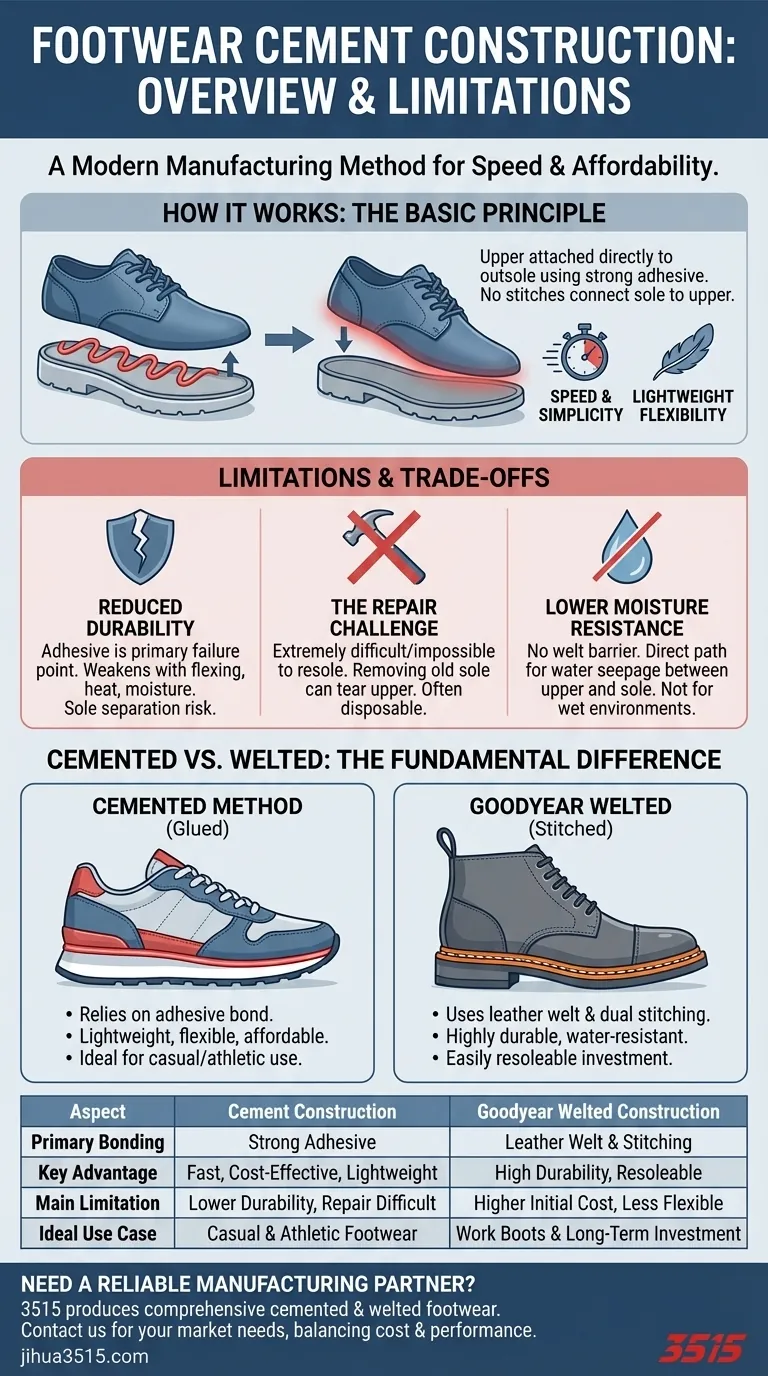

How Cement Construction Works

The Basic Principle

In the simplest terms, the shoe's upper is shaped and then bonded directly to the sole with a powerful adhesive, or cement. There are no stitches connecting the sole to the upper.

Speed and Simplicity

This method is the backbone of mass-market footwear production. It requires fewer steps and less specialized machinery than welted construction, making it significantly faster and more economical.

Lightweight Flexibility

By eliminating extra layers and stitching, such as a welt, cemented shoes are often lighter and more flexible right out of the box. This makes the method ideal for athletic and casual footwear where immediate comfort is paramount.

Understanding the Trade-offs and Limitations

Reduced Durability

The adhesive bond is the shoe's primary point of failure. Over time, constant flexing, heat, and moisture can weaken the glue, causing the sole to separate from the upper. This construction does not hold up well in rugged conditions.

The Repair Challenge

Re-soling a cemented shoe is extremely difficult, and often impossible. Attempting to pull the old sole off can tear the upper material, permanently damaging the shoe. Unlike stitched shoes, they are generally considered disposable once the sole wears out.

Lower Moisture Resistance

Without a welt or durable stitching creating a barrier, water has a more direct path to seep in between the upper and the sole. This makes cemented shoes less suitable for consistently wet environments.

Cemented vs. Welted: The Fundamental Difference

The Cemented Method: Glued for Flexibility

This approach relies entirely on adhesives to bond the shoe together. Its strengths are in creating lightweight, flexible, and affordable footwear for less demanding use cases.

The Goodyear Welted Method: Stitched for Longevity

Considered a hallmark of high-quality shoemaking, this method uses a strip of leather (the "welt") and two independent stitches to attach the upper and sole. This creates a highly durable, water-resistant, and easily repairable shoe, as the sole can be replaced without disturbing the upper.

Making the Right Choice for Your Needs

Choosing the right construction depends entirely on your intended use and priorities.

- If your primary focus is affordability and out-of-the-box comfort for casual wear: Cemented construction, found in most sneakers and everyday shoes, is the perfect choice.

- If your primary focus is long-term durability and value in a dress or work boot: A Goodyear welted construction is a superior investment that can be repaired for years of service.

- If your primary focus is lightweight performance for a specific activity: Cemented footwear often provides the necessary flexibility and reduced weight required for athletic pursuits.

Ultimately, understanding how your footwear is built empowers you to select the right tool for the job.

Summary Table:

| Aspect | Cement Construction | Goodyear Welted Construction |

|---|---|---|

| Primary Bonding Method | Strong Adhesive | Leather Welt & Stitching |

| Key Advantage | Fast, Cost-Effective, Lightweight | High Durability, Resoleable |

| Main Limitation | Lower Durability, Difficult to Repair | Higher Initial Cost, Less Flexible |

| Ideal Use Case | Casual & Athletic Footwear | Work Boots & Long-Term Investment Shoes |

Need a reliable manufacturing partner for your footwear line? As a large-scale manufacturer, 3515 produces a comprehensive range of cemented and welted footwear for distributors, brand owners, and bulk clients. Our expertise ensures you get the right construction method for your market needs, balancing cost, durability, and performance. Contact 3515 today to discuss your production requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture