At its core, a vulcanized sole is a rubber sole that has been chemically transformed through a high-heat curing process. This method, originally developed for manufacturing durable tires, involves baking the rubber to bond it with other materials, creating a single, fused piece that is significantly more durable, flexible, and wear-resistant than raw rubber.

The essential difference of a vulcanized shoe is its construction: the rubber sole is heated until it melts and fuses directly to the shoe's upper. This creates a remarkably flexible shoe with superior grip, prized for its direct connection between the foot and the ground.

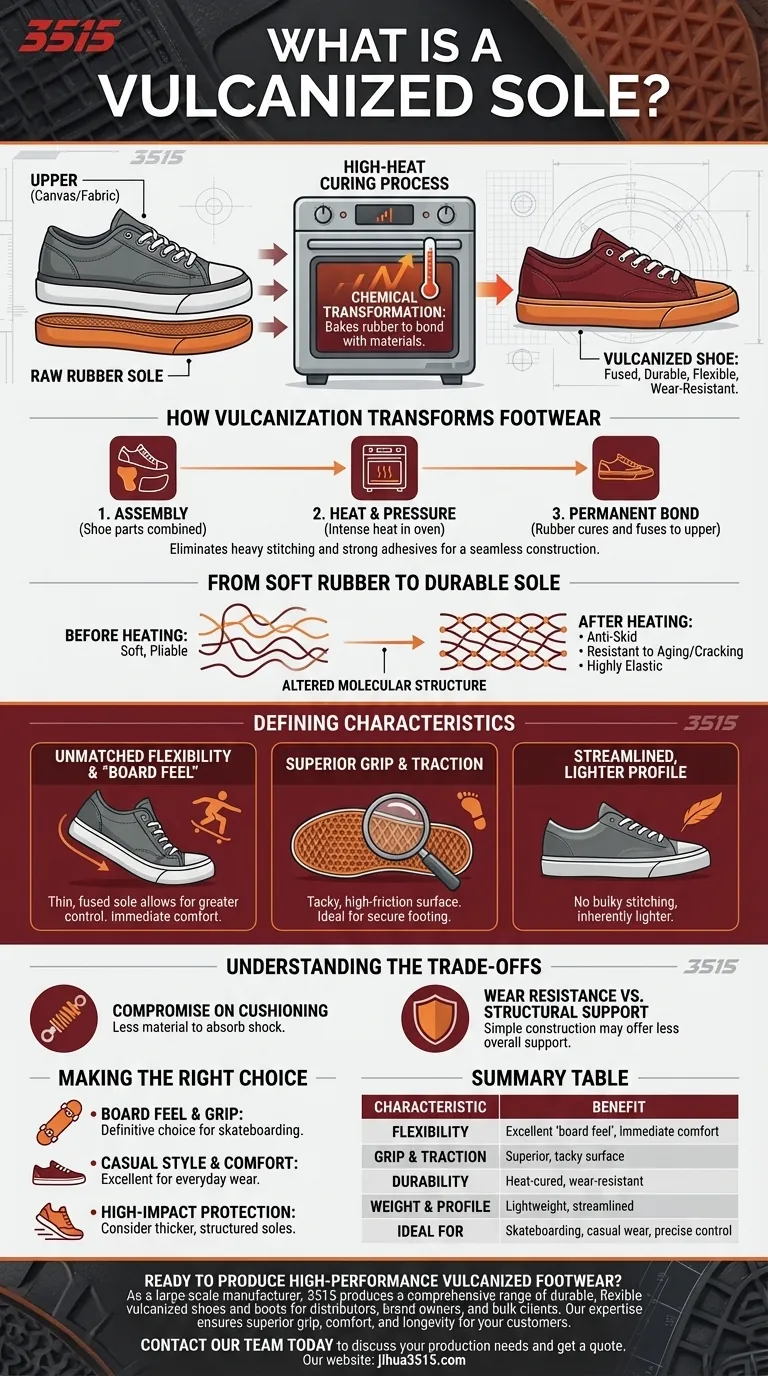

How Vulcanization Transforms Footwear

The Core Process: Heat and Pressure

The manufacturing technique involves assembling the shoe and then placing it in a high-temperature oven. This intense heat causes the rubber to cure, harden, and permanently bond to the canvas or fabric upper of the shoe.

This process eliminates the need for heavy stitching or strong adhesives to connect the sole, resulting in a simpler, more integrated construction.

From Soft Rubber to Durable Sole

Before heating, the rubber is soft and pliable. The vulcanization process fundamentally alters its molecular structure, making it anti-skid, resistant to aging and cracking, and highly elastic.

This transformation is what gives the sole its signature durability and performance characteristics.

The Defining Characteristics of a Vulcanized Sole

Unmatched Flexibility and "Board Feel"

Because vulcanized soles are thin, light, and fused as a single unit, they offer exceptional flexibility right out of the box.

This creates an excellent "board feel," a term used by skateboarders to describe the ability to feel the board's shape and movement through the shoe, allowing for greater control.

Superior Grip and Traction

The heat-cured rubber creates a tacky, high-friction surface. This results in outstanding grip, making vulcanized footwear a top choice for activities like skateboarding or any application where secure footing is critical.

A Streamlined, Lighter Profile

The construction method results in a shoe with a sleeker, more streamlined silhouette. With no bulky stitching or thick layers of glue, the final product is inherently lighter and less rigid than many other types of athletic footwear.

Understanding the Trade-offs

The Compromise on Cushioning

The primary trade-off for excellent board feel is a reduction in cushioning and impact support. The thinness of the sole means there is less material to absorb shock from jumps or long periods of walking on hard surfaces.

Break-In Period

A significant advantage is that vulcanized shoes require very little break-in time. Their inherent flexibility makes them comfortable and ready for performance almost immediately.

Wear Resistance vs. Structural Support

While the rubber itself is highly wear-resistant, the simple construction may offer less overall structural support for the foot compared to more complex, multi-layered soles designed for high-impact sports.

Making the Right Choice for Your Goal

Choosing a shoe with a vulcanized sole depends entirely on your performance priorities.

- If your primary focus is board feel and grip: A vulcanized sole is the definitive choice for skateboarding and similar activities requiring precise control.

- If your primary focus is casual style and comfort: The lightweight, flexible nature of these shoes makes them an excellent option for everyday wear.

- If your primary focus is high-impact protection and cushioning: You may want to consider footwear with thicker, more structured soles designed to absorb significant shock.

Ultimately, understanding vulcanization empowers you to select footwear based on the precise performance characteristics you truly need.

Summary Table:

| Characteristic | Benefit |

|---|---|

| Flexibility | Excellent 'board feel' and immediate comfort |

| Grip & Traction | Superior, tacky surface ideal for skateboarding |

| Durability | Heat-cured rubber is wear-resistant and long-lasting |

| Weight & Profile | Lightweight and streamlined due to fused construction |

| Ideal For | Skateboarding, casual wear, activities requiring precise foot control |

Ready to produce high-performance vulcanized footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, flexible vulcanized shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures superior grip, comfort, and longevity for your customers.

Contact our team today to discuss your production needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene