At its core, a nano composite toe is a type of safety toecap for footwear that uses advanced materials to achieve protection without the weight and bulk of traditional steel. It is constructed by infusing a fiberglass resin with incredibly small carbon nanotubes—microscopic cylinders of carbon atoms arranged in a strong, honeycomb-like pattern. This combination creates a material that is exceptionally strong, lightweight, and meets rigorous ASTM safety standards.

The true innovation of nano composite technology is not just protection, but protection with less compromise. It allows for safety footwear that is significantly lighter and more spacious, directly enhancing wearer comfort and reducing fatigue throughout the workday.

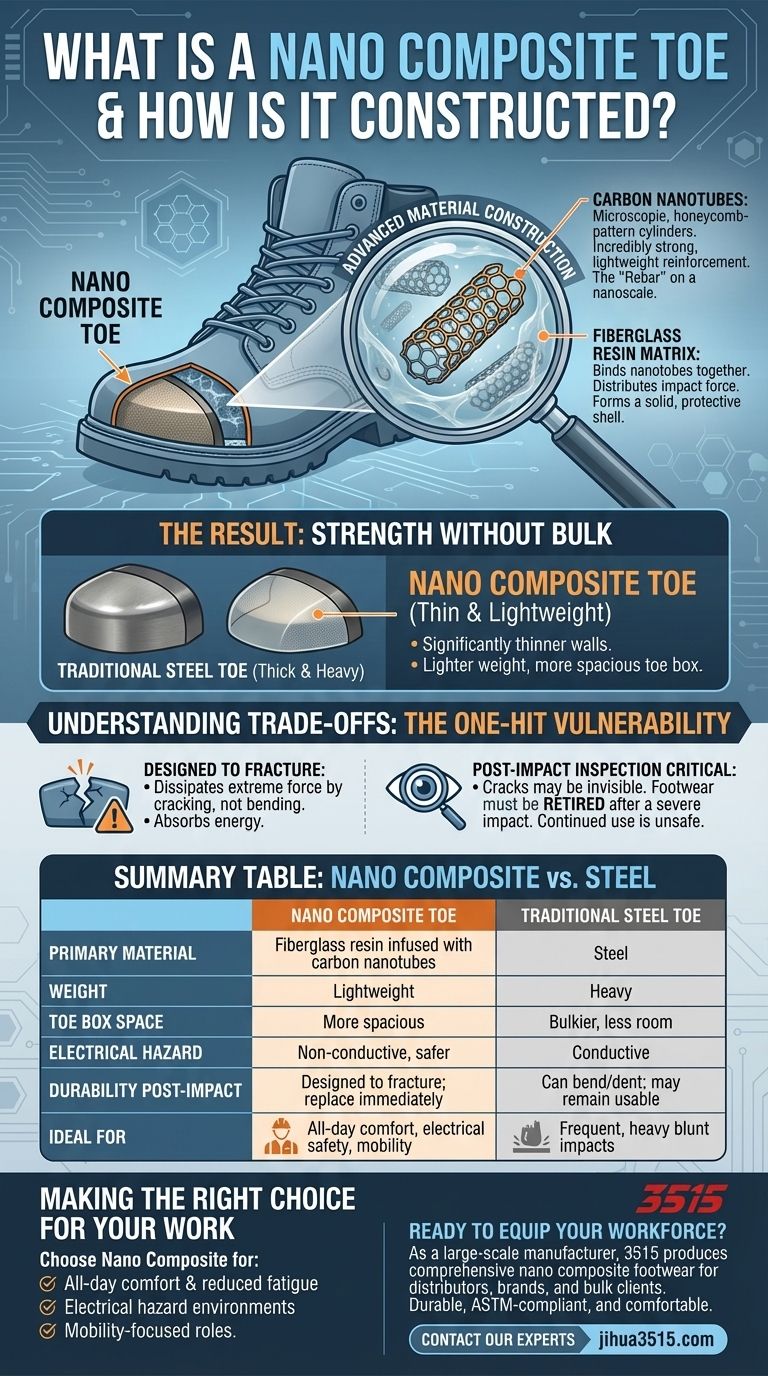

How Nano Composite Toes Achieve Their Strength

To understand the value of this technology, we must first look at its unique construction at a microscopic level. The final material is more than the sum of its parts.

The Role of Carbon Nanotubes

The key ingredient is the carbon nanotube. These are minuscule structures of carbon atoms arranged in a hexagonal, beehive-like pattern and then rolled into a seamless cylinder.

This specific atomic arrangement gives them one of the highest strength-to-weight ratios of any known material. They act as a microscopic reinforcement, much like rebar in concrete, but on an incredibly small and efficient scale.

The Fiberglass Resin Matrix

The carbon nanotubes are suspended within a fiberglass resin matrix. This resin binds the individual nanotubes together, distributing the force of an impact across the entire structure of the toecap.

Without the resin, the nanotubes would not be able to form a solid, protective shell. The resin acts as the body, while the nanotubes provide the powerful, reinforcing skeleton.

The Result: Strength Without Bulk

This combination of a strong nano-scale reinforcement within a binding matrix creates an incredibly tough material. Because it is so strong, the walls of the toecap can be made significantly thinner than those of a standard composite toe.

This reduction in material is what leads to the two primary benefits: a lighter overall weight and more room inside the toe box of the boot.

Understanding the Trade-offs and Limitations

No material is without its compromises. Acknowledging the limitations of nano composite toes is essential for making an informed safety decision.

The "One-Hit" Vulnerability

Unlike steel, which can often bend or dent upon impact, a nano composite toe is designed to dissipate extreme force by fracturing. If a sufficiently heavy object impacts the toecap, it may visibly or invisibly crack as it absorbs the energy.

This means that in the event of a severe incident, the footwear has done its job but is no longer safe for use. It must be replaced immediately.

The Importance of Post-Impact Inspection

Because a fracture may not always be obvious, any footwear with a nano composite toe that has sustained a significant impact should be retired from service.

Continuing to wear compromised footwear provides a false sense of security and puts the user at serious risk of injury in a future incident.

Making the Right Choice for Your Work

Selecting the right safety toe depends entirely on the demands of your environment and your personal comfort needs.

- If your primary focus is all-day comfort and mobility: Nano composite toes are an excellent choice, as their lightweight nature significantly reduces leg fatigue.

- If you work in an environment with electrical hazards: The non-metallic, non-magnetic properties of nano composite toes make them a superior and safer option over steel.

- If you work where frequent, heavy impacts are a daily risk: While nano composite meets the safety standards, you must be diligent about replacing your boots after any significant incident.

Ultimately, nano composite technology empowers you to have top-tier safety protection without sacrificing comfort.

Summary Table:

| Feature | Nano Composite Toe | Traditional Steel Toe |

|---|---|---|

| Primary Material | Fiberglass resin infused with carbon nanotubes | Steel |

| Weight | Lightweight | Heavy |

| Toe Box Space | More spacious | Bulkier, less room |

| Electrical Hazard | Non-conductive, safer | Conductive |

| Durability Post-Impact | Designed to fracture; must be replaced after a severe impact | Can often bend or dent; may remain usable |

| Ideal For | All-day comfort, electrical hazard environments, mobility-focused work | Environments with frequent, heavy blunt impacts |

Ready to equip your workforce with the advanced protection and superior comfort of nano composite safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear featuring nano composite toes for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, ASTM-compliant boots that keep your team safe and comfortable all day long.

Contact our experts today to discuss your specific needs and discover the right safety solution for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What is a simple method to check if safety toe boots have adequate toe clearance? The Definitive Fit Test

- What industries commonly use composite toe work boots? Choose Lightweight, Non-Conductive Safety Footwear

- What makes safety footwear durable and long-lasting? Key Materials & Construction Methods

- What is the importance of a manual angle adjustment mechanism in slip resistance testing? Ensure Maximum Footwear Safety

- How do professional specialty footwear support neuromuscular walking impairments? Enhance Mobility and Biomechanical Safety

- Where is protective footwear addressed in OSHA standards? Understanding 29 CFR 1910.136 Compliance

- Why should the design of high-risk foot protective footwear aim for a higher Pressure Gradient Angle (PGA)?

- Why are puncture-resistant soles considered indispensable for scaffolding? Essential Safety for High-Height Construction