OSHA specifically addresses protective footwear in standard 29 CFR 1910.136(a), located within the Personal Protective Equipment (PPE) section of the Occupational Safety and Health Standards. This regulation mandates that employers ensure employees utilize protective footwear when working in areas presenting dangers such as falling or rolling objects, objects that could pierce the sole, or exposure to electrical hazards.

Compliance extends beyond simply wearing boots; it requires a documented hazard assessment to ensure footwear is ASTM-certified for specific risks and a clear understanding of financial responsibility based on the equipment's usability off the job site.

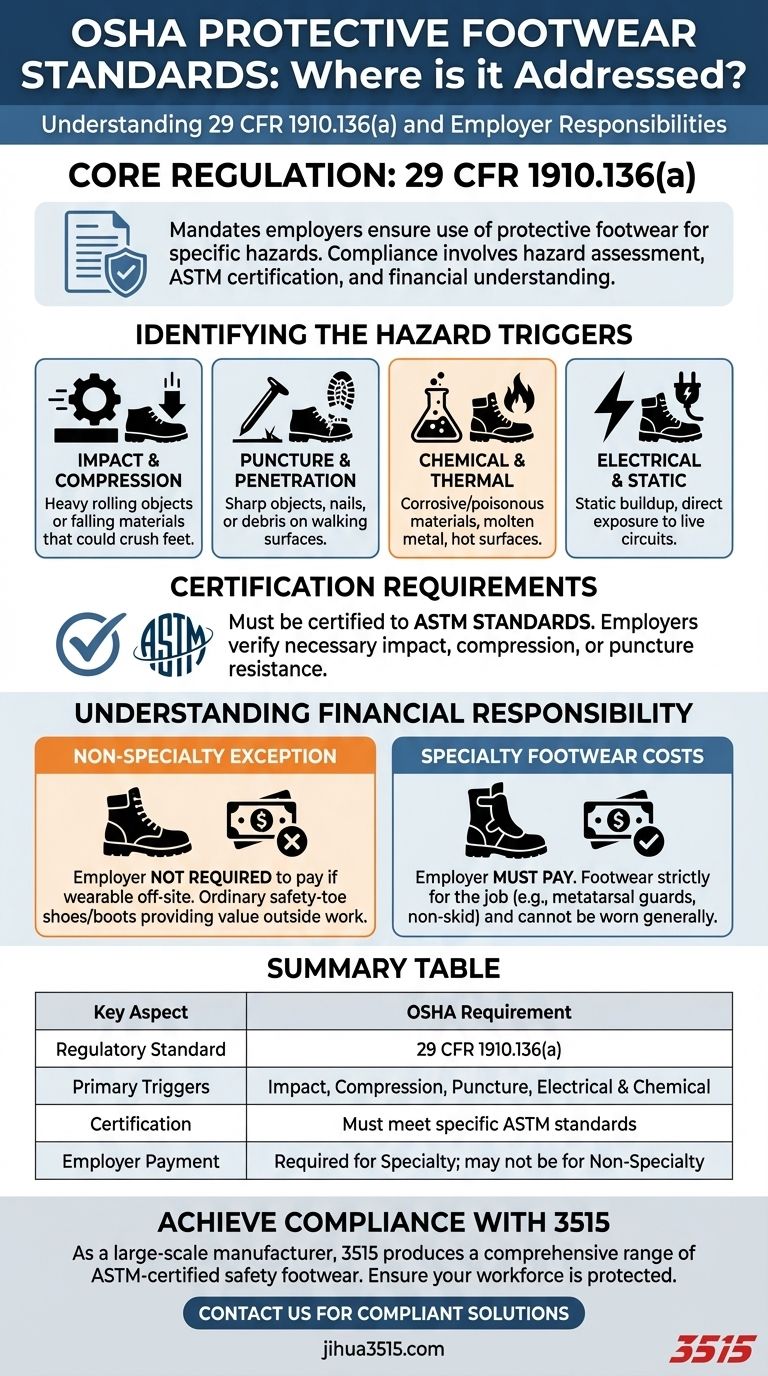

Identifying the Hazard Triggers

To determine if 29 CFR 1910.136 applies to your environment, you must evaluate the presence of specific physical dangers. OSHA does not require safety shoes for every worker, but rather for those facing distinct risks.

Impact and Compression Hazards

The most common trigger for this standard is the presence of heavy rolling objects or materials that could fall.

If your facility involves moving heavy equipment, inventory, or industrial machinery, the risk of crushing injuries necessitates protection.

Puncture and Penetration Risks

Workplaces containing sharp objects capable of piercing a shoe's sole require specialized footwear.

This often applies to construction sites or industrial areas where nails, scrap metal, or other debris are common on walking surfaces.

Chemical and Thermal Exposure

OSHA recommends protective footwear for environments involving corrosive or poisonous materials.

This also extends to situations involving molten metal splashes or contact with hot surfaces that could cause burns or compromise standard footwear.

Electrical and Static Hazards

Footwear must be considered when there is a risk of static electricity buildup or direct exposure to electrical hazards.

Conductive or non-conductive footwear is chosen based on whether the goal is to ground the worker or isolate them from live circuits.

Certification Requirements

Simply wearing "sturdy boots" is often insufficient to meet the standard.

Adherence to ASTM Standards

The footwear selected must be certified to ASTM standards to ensure it can withstand the specific hazards identified.

Employers are responsible for verifying that the equipment provides the necessary level of impact, compression, or puncture resistance required by the job.

Understanding the Financial Trade-offs

One of the most nuanced aspects of the PPE standard involves the responsibility for payment. While employers generally bear the cost of safety equipment, protective footwear has a specific "carve-out" rule.

The Non-Specialty Exception

OSHA standards state that employers are not required to pay for non-specialty safety-toe protective footwear if the employer permits these items to be worn off the job site.

This exception exists because these items are viewed as personal apparel that provides value to the employee outside of work hours.

Defining Non-Specialty Footwear

"Non-specialty" refers to footwear that provides the protection of an ordinary safety-toe shoe or boot.

If the footwear is not designed for special use on the job (such as a standard steel-toe work boot), the cost can legally be shifted to the employee.

Specialty Footwear Costs

Conversely, if the job requires specialty footwear that offers protection beyond ordinary safety shoes (such as metatarsal guards or non-skid shoes for wet environments) and cannot be worn generally, the employer must pay.

In these cases, the equipment is strictly a tool for the job, and the financial burden remains with the company.

Making the Right Choice for Your Compliance Strategy

Ensuring you meet the requirements of 29 CFR 1910.136 involves balancing safety audits with clear policy on equipment ownership.

- If your primary focus is Hazard Mitigation: Conduct a thorough walkthrough to identify rolling objects, sharps, or electrical risks, ensuring all selected footwear carries the appropriate ASTM certification for those specific threats.

- If your primary focus is Budget Management: Determine which required footwear falls under the "non-specialty" category and establish a policy allowing off-site use to legally shift the purchasing cost to the employee.

True compliance is achieved when the footwear matches the hazard and the procurement policy matches the regulation.

Summary Table:

| Key Aspect | OSHA Requirement |

|---|---|

| Regulatory Standard | 29 CFR 1910.136(a) |

| Primary Triggers | Impact/compression, puncture, electrical, & chemical hazards |

| Certification | Footwear must meet specific ASTM standards |

| Employer Payment | Required for specialty footwear; may not be for non-specialty if wearable off-site |

Ensure Your Team is Fully Compliant and Protected

Navigating OSHA standards for protective footwear is critical for workplace safety and legal compliance. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear and boots designed to meet the specific hazards outlined in 29 CFR 1910.136. We provide durable, reliable footwear for distributors, brand owners, and bulk clients, ensuring your workforce is protected from impact, puncture, electrical, and chemical risks.

Let us help you mitigate risks and manage costs effectively.

Contact us today for a consultation on compliant footwear solutions tailored to your operational hazards.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What is the minimum order quantity for oil resistant safety boots? Navigate MOQs from 100 to 1,000 Pairs

- How do industrial-grade safety shoes protect technicians from mechanical hazards in a repair shop environment? Explained

- Why is puncture-resistant technology critical for industrial safety shoes? Protect Workers with High-Strength Barriers

- What are the main types of safety toe caps? Choose the Right Protection for Your Job

- Why should preoperative assessments for foot surgery include safety shoe evaluation? Ensure Functional Return to Work

- What is the purpose of using smart motion trackers during the biomechanical assessment of safety footwear? Precision Data

- What are the benefits of waterproofing liners in safety shoes? Achieve Superior Foot Protection & Comfort

- What are some common additional markings for safety shoes and their meanings? Decode Your Boot's Safety Standards