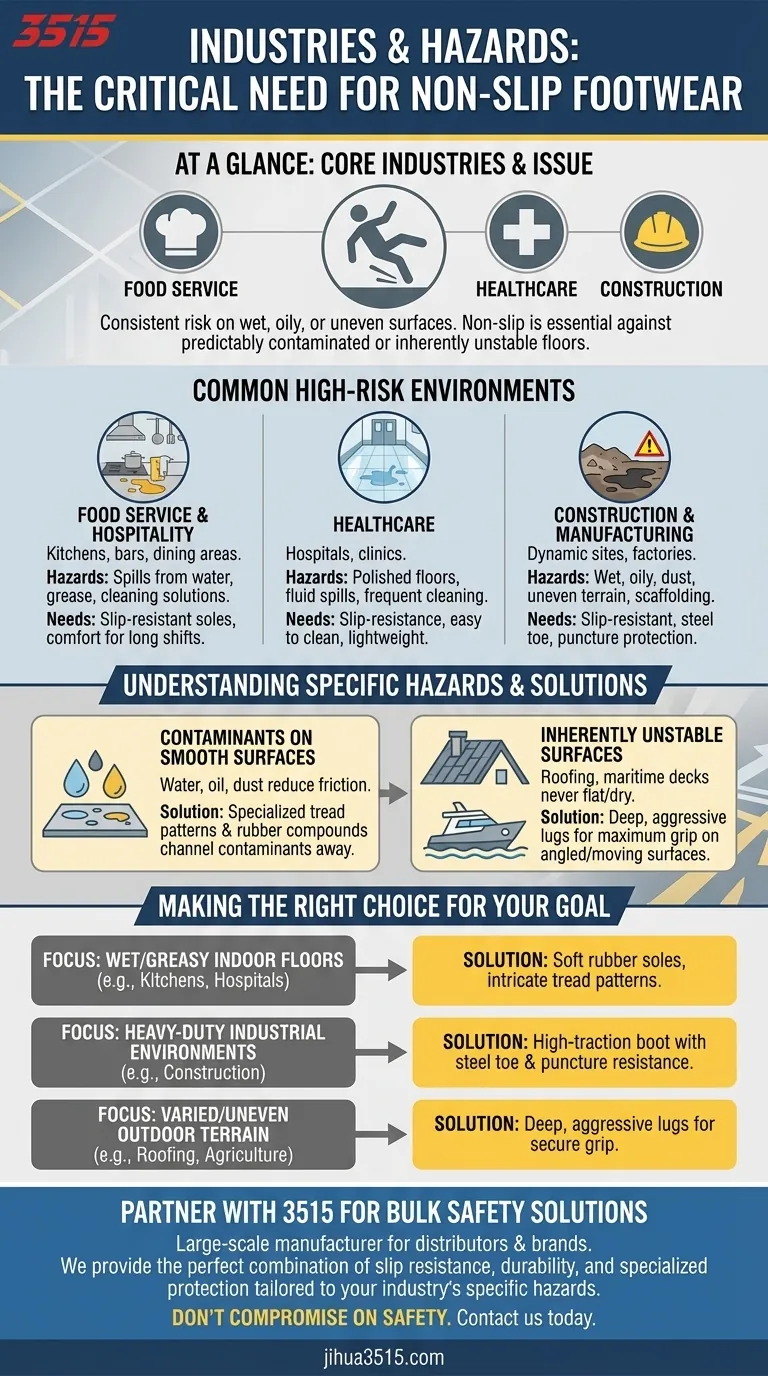

At a glance, the industries that most commonly require non-slip footwear are food service, healthcare, and construction. These environments consistently feature wet, oily, or uneven surfaces where the risk of slips, trips, and falls is exceptionally high.

The core issue isn't just about specific industries, but about specific environmental hazards. Non-slip footwear is essential wherever floors are predictably contaminated with liquids like water, grease, or chemicals, or where surfaces are inherently uneven.

Why Some Industries Mandate Non-Slip Footwear

The requirement for non-slip shoes is a direct response to common workplace hazards. It's about mitigating the risk of falls, which are a leading cause of workplace injuries. The environments in these industries create a constant threat to stable footing.

The Most Common High-Risk Environments

Food Service and Hospitality: This is arguably the most recognized sector for slip-and-fall risks. Kitchens, bars, and dining areas are prone to spills from water, grease, and cleaning solutions, creating slick, hazardous floors.

Healthcare: Hospitals, clinics, and care facilities have constantly polished floors that are frequently being cleaned. Spills of various fluids are a daily reality, making secure footing essential for fast-moving medical staff.

Construction and Manufacturing: These sites are dynamic and unpredictable. Surfaces can be wet, oily, or covered in dust and debris. Workers also navigate uneven terrain, scaffolding, and ladders where a single slip can be catastrophic.

The Specific Hazards Driving the Need

Understanding the specific risk in each environment clarifies why a simple sneaker isn't enough. The design of non-slip footwear directly counters these threats.

Contaminants on Smooth Surfaces

Many workplaces, like supermarkets, schools, and warehouses, have smooth, hard-surface floors. The primary danger here is contamination.

A thin layer of water, oil, or even dust can drastically reduce the friction between a shoe sole and the floor. The specialized tread patterns and rubber compounds in non-slip shoes are engineered to channel these contaminants away and maintain grip.

Inherently Unstable Surfaces

Some jobs require working on surfaces that are never perfectly flat or dry.

Roofing is a clear example, where workers need maximum grip on steep and potentially weathered surfaces. Similarly, maritime workers on boats face constantly wet and moving decks, demanding soles that are both waterproof and high-traction.

The Need for Additional Protections

In many industries, slip resistance is just one of several required safety features.

Construction and factory work often demands steel-toe protection, puncture-resistant soles, and even metatarsal guards to protect against falling objects. Healthcare footwear often needs to be easily sterilized and resistant to bacteria.

Understanding the Trade-offs

Choosing footwear is not just about maximizing grip. Other factors come into play, creating a balance of needs.

Comfort vs. Maximum Safety

The most protective, heavy-duty boots might offer excellent grip and impact resistance but can be heavy and inflexible. For workers on their feet for 12-hour shifts, like nurses or chefs, lightweight and comfortable non-slip shoes are often prioritized over heavy protective features.

Durability vs. Cost

High-quality non-slip footwear made with durable rubber compounds and robust construction costs more. While cheaper options exist, they often wear down faster, losing their effective grip and requiring more frequent replacement.

Specialized vs. General Use

A shoe designed for a greasy kitchen floor may not have the ideal tread for a muddy agricultural field. The specific environment dictates the optimal sole design, meaning there is no single "best" non-slip shoe for all industries.

Making the Right Choice for Your Goal

Ultimately, the right footwear depends entirely on the specific hazards you face daily.

- If your primary focus is on wet or greasy indoor floors (e.g., kitchens, hospitals): Prioritize shoes with soft rubber soles and intricate tread patterns designed to channel liquids away.

- If your primary focus is on heavy-duty industrial or construction environments: You need a boot that combines a high-traction sole with mandatory safety features like steel toes and puncture resistance.

- If your primary focus is on varied or uneven outdoor terrain (e.g., roofing, agriculture): Look for deep, aggressive lugs on the sole that can grip securely on loose or angled surfaces.

Choosing the right footwear is a critical first step in ensuring your safety in any demanding work environment.

Summary Table:

| Industry | Primary Hazards | Key Footwear Needs |

|---|---|---|

| Food Service & Hospitality | Wet floors, grease, cleaning solutions | Slip-resistant soles, comfort for long shifts |

| Healthcare | Polished floors, fluid spills | Slip-resistance, easy to clean, lightweight |

| Construction & Manufacturing | Uneven terrain, oil, debris | Slip-resistant, steel toe, puncture protection |

| Maritime & Roofing | Constantly wet/moving surfaces, steep angles | Aggressive tread, waterproof, maximum grip |

Ensure your team's safety with the right non-slip footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Whether your team works in a greasy kitchen, a busy hospital, or a demanding construction site, we can provide the perfect combination of slip resistance, durability, and specialized protection (like steel toes) tailored to your specific industry hazards.

Don't compromise on safety—contact us today for a consultation and let 3515 be your trusted partner in workplace safety.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene