For a welder, work boots are not just footwear; they are a critical piece of personal protective equipment. The right pair must offer robust protection against the unique and severe hazards of the trade, including molten metal sparks, falling heavy objects, and potential electrical currents. The most important features to look for are a full-grain leather upper, a pull-on design, a certified safety toe, and a heat-resistant, Electrical Hazard (EH) rated sole.

Your choice of work boot is a decision about risk management. The ideal welder's boot functions as a seamless shield, prioritizing a heat-resistant barrier and impact protection over all other features to protect you from the specific dangers you face daily.

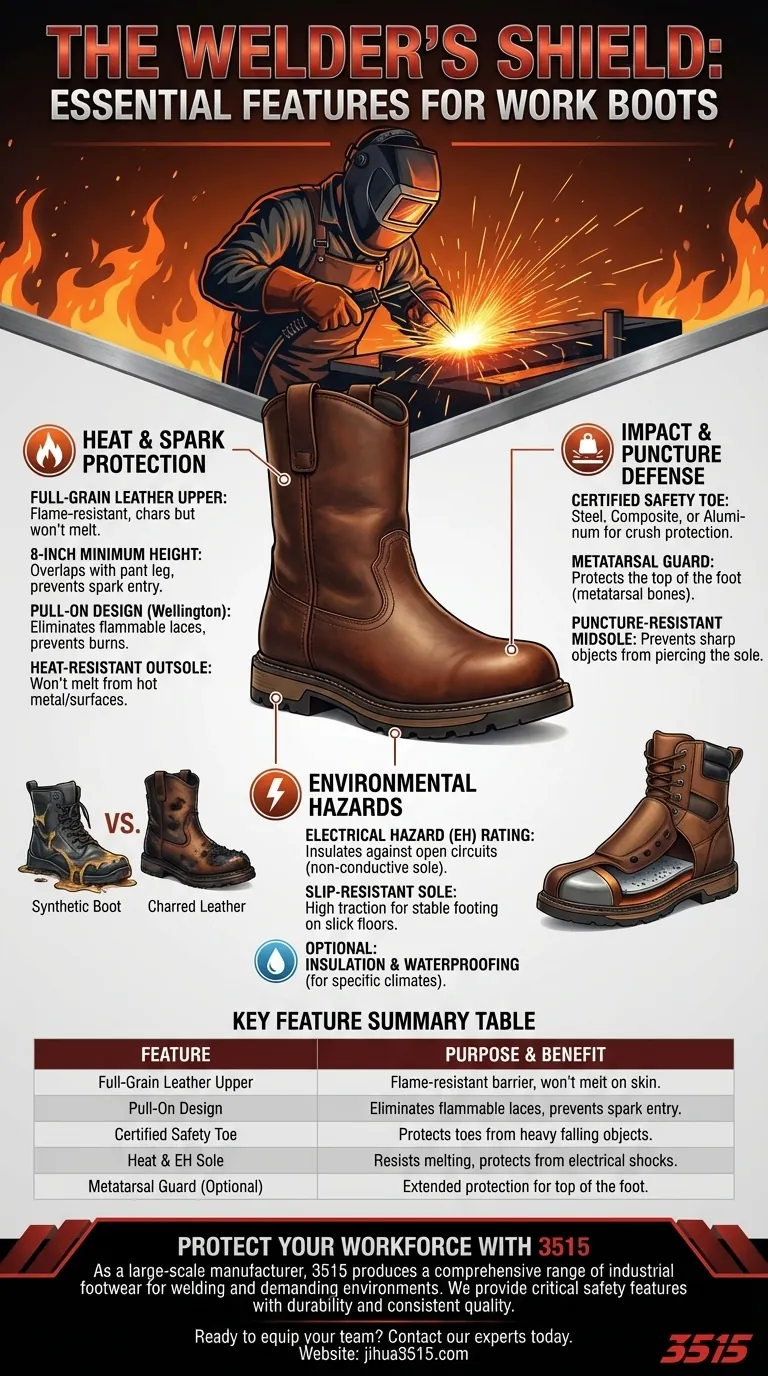

The Non-Negotiable Foundation: Heat and Spark Protection

The primary hazard for any welder is the constant presence of extreme heat, sparks, and molten slag. Your boots are the first and last line of defense for your feet.

Why Full-Grain Leather is the Standard

Full-grain leather is the material of choice for welding boots because it is naturally durable and flame-resistant. Unlike synthetic fabrics that can melt and adhere to the skin when exposed to high heat, leather will char but not melt, providing a crucial protective layer.

The Critical Role of a High-Top Design

Look for boots with an upper that is at least 8 inches high. This height allows your pant leg to overlap the top of the boot, creating a seal that prevents hot sparks and slag from falling inside where they can cause severe burns.

Pull-On Boots vs. Laces

Whenever possible, a pull-on boot (like a Wellington) is the superior choice for a welder. Traditional laces can catch sparks, burn through, and create a pathway for hot embers to reach your foot. If a lace-up boot is necessary, ensure the laces themselves are made from a flame-resistant material like Kevlar.

The Importance of Heat-Resistant Outsoles

The outsole of your boot must be made from a high-heat resistant material. This ensures the sole will not melt, deform, or separate if you accidentally step on a piece of hot metal or walk across a surface heated by the welding process.

Guarding Against Impact and Puncture Hazards

Welding and fabrication shops are dynamic environments filled with heavy steel and sharp scraps, making robust physical protection essential.

Safety Toes: Your Shield Against Impact

A certified safety toe is mandatory. These can be made of steel, composite, or aluminum and are designed to protect your toes from being crushed by heavy falling or rolling objects. All certified types provide the necessary impact resistance.

Metatarsal Guards: The Next Level of Protection

For maximum safety, consider boots with a built-in metatarsal guard. This feature adds a protective plate over the top of your foot (the metatarsal bones), shielding a vulnerable area that a standard safety toe does not cover.

Puncture-Resistant Midsoles

Many shop floors are littered with sharp metal off-cuts. A puncture-resistant plate in the midsole prevents these sharp objects from piercing the sole of your boot and injuring your foot.

Understanding Environmental Risks

Beyond heat and impact, you must also be protected from the surfaces you stand on.

Electrical Hazard (EH) Rating

An Electrical Hazard (EH) rating is a critical safety feature. It signifies that the boot's sole and heel are constructed with non-conductive materials that can protect you from open electrical circuits up to a specific voltage, a common risk in many workshops.

The Need for a Slip-Resistant Sole

Shop floors are often smooth concrete and can become slick with dust, oil, or other fluids. A high-traction, slip-resistant outsole is vital for maintaining stable footing and preventing falls.

Understanding the Trade-offs: Safety vs. Other Features

While modern boots offer many features, for a welder, core protection must always come first.

Prioritizing Protection Over Breathability

Features like mesh panels that enhance breathability are a liability for welders. These materials offer no protection from sparks and can melt easily. A solid leather construction is always the safer choice.

Comfort is a Function of Fit, Not a Feature

While comfort is crucial for long shifts, it should come from a proper fit, a quality cushioned insole, and good arch support—not from compromising on protective materials. A well-made boot should feel supportive, not restrictive, from the first wear.

Conditional Needs: Insulation and Waterproofing

Insulation and waterproofing are features to consider based on your specific environment. If you work on a cold concrete floor, in a drafty shop, or on an outdoor job site, these additions are essential for comfort and safety. For indoor-only work in a climate-controlled shop, they are less critical.

Making the Right Choice for Your Goal

Your specific welding environment should guide your final decision.

- If your primary focus is shop fabrication and general welding: Prioritize a pull-on, full-grain leather boot with a safety toe, metatarsal guard, and an EH-rated, slip-resistant sole.

- If your primary focus is outdoor or heavy industrial work: Seek out all the core safety features but add waterproofing, a puncture-resistant sole, and insulation appropriate for your climate.

- If your primary focus is maximum comfort during long shifts: Do not compromise on safety. Instead, focus on finding a brand known for excellent fit and invest in high-quality insoles that provide the arch support you need.

A well-chosen boot is a fundamental tool that directly contributes to your safety, focus, and productivity on the job.

Summary Table:

| Key Feature | Purpose & Benefit |

|---|---|

| Full-Grain Leather Upper | Provides a flame-resistant barrier that chars but won't melt onto skin. |

| Pull-On (Wellington) Design | Eliminates flammable laces, preventing sparks from entering the boot. |

| Certified Safety Toe | Protects toes from crushing injuries caused by heavy falling objects. |

| Heat & Electrical Hazard (EH) Sole | Resists melting from hot metal and protects against electrical shocks. |

| Metatarsal Guard (Optional) | Offers extended protection for the top of the foot from impact. |

Protect Your Workforce with the Right Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear specifically engineered for demanding environments like welding. We provide distributors, brand owners, and bulk clients with boots that combine critical safety features—like full-grain leather, EH-rated soles, and safety toes—with the durability and consistent quality required for professional use.

Ready to equip your team with superior protection? Contact our experts today to discuss your specific needs and explore our extensive catalog of safety boots.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Why is rotating two pairs of work boots recommended? Double Boot Life & Boost Foot Health

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- How long do work boots typically last? Maximize Lifespan & Safety

- Why is it important to invest in a good pair of work boots? Maximize Safety & Save Money Long-Term