For any specialized work environment, the key is to select gear with features that directly counteract the specific hazards present. This includes protection from electrical currents, extreme temperatures, and physical or chemical intrusion, as well as features that manage water exposure and allow for customized comfort.

The most effective approach isn't to find gear with the most features, but to accurately identify the risks of your environment and choose the precise protections required to mitigate them.

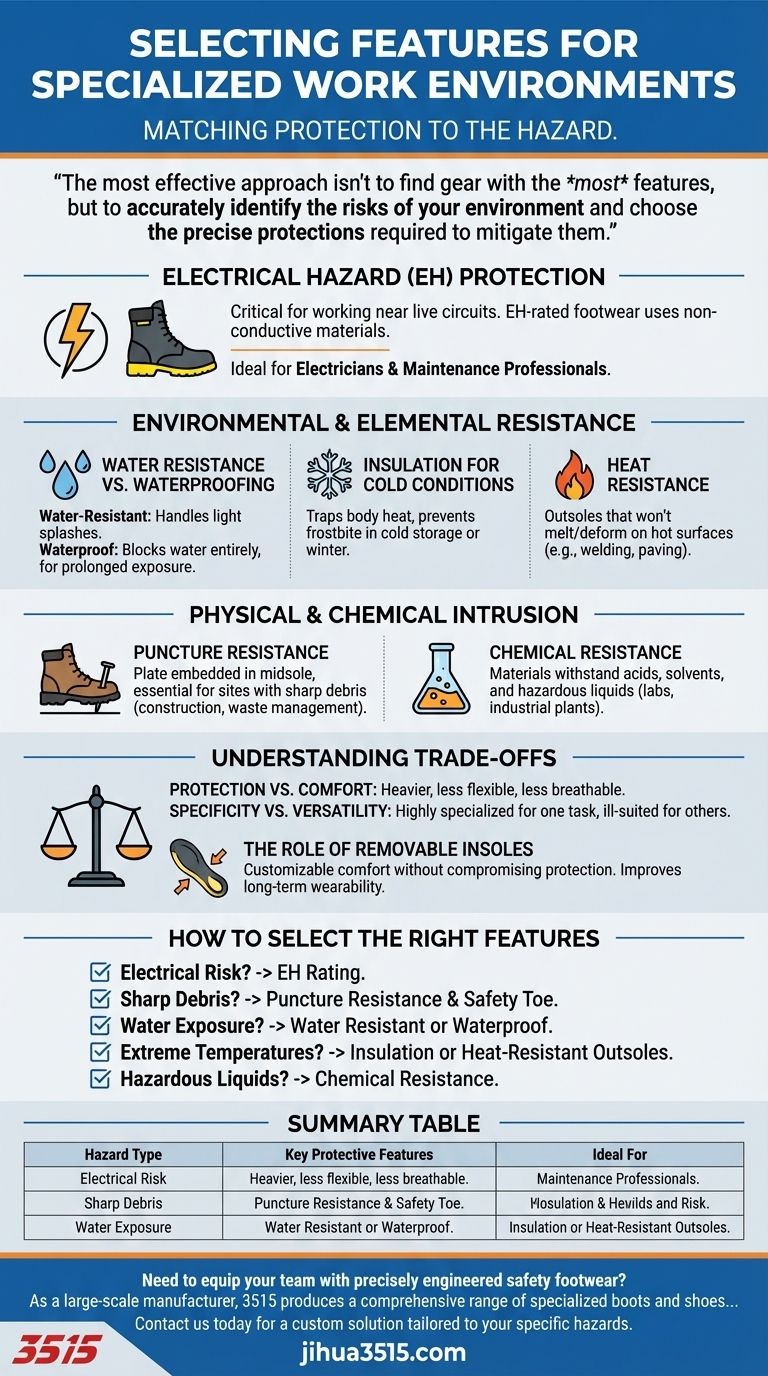

Matching Protection to the Hazard

Your primary task is to conduct a risk assessment of your environment. Once the specific dangers are known, you can match them to the corresponding protective features designed to keep you safe and effective.

Electrical Hazard (EH) Protection

This feature is critical for anyone working near live electrical circuits, such as electricians or maintenance professionals. EH-rated footwear is constructed with non-conductive materials to provide a secondary source of protection from electrocution.

Environmental and Elemental Resistance

Many job sites expose workers to extreme weather or temperatures. Selecting the right level of elemental resistance is crucial for both safety and performance.

Water Resistance vs. Waterproofing

These terms are not interchangeable. Water-resistant gear can handle light splashes or brief rain, but will eventually become saturated. Waterproof gear features a membrane or sealed seams designed to block water from entering entirely, even during prolonged exposure or submersion.

Insulation for Cold Conditions

For those working in cold storage, winter weather, or other low-temperature environments, insulation is non-negotiable. It works by trapping body heat, preventing heat loss and protecting against cold-related injuries like frostbite.

Heat Resistance

This feature is designed for environments with high ambient temperatures or where contact with hot surfaces is likely, such as in welding, paving, or foundry work. Heat-resistant outsoles will not melt or deform when exposed to high heat.

Physical and Chemical Intrusion

This category of protection shields you from direct, harmful contact with objects and substances on the job site.

Puncture Resistance

A puncture-resistant plate, typically made of steel or a composite material, is embedded in the midsole of footwear. It is essential for construction, demolition, and waste management sites where sharp objects like nails or scrap metal pose a constant threat.

Chemical Resistance

For work in laboratories, industrial plants, or agricultural settings, chemical resistance is vital. The materials used are specifically engineered to withstand degradation and permeation from acids, solvents, and other hazardous liquids.

Understanding the Trade-offs

Selecting specialized features is rarely a simple "more is better" decision. Nearly every protective feature comes with a trade-off that can impact comfort, mobility, or performance in other areas.

Protection vs. Comfort

Heavily protected gear is often heavier, stiffer, and less breathable. A fully waterproof and puncture-resistant boot, for example, will be less flexible and retain more heat than a standard work boot, potentially leading to fatigue over a long shift.

Specificity vs. Versatility

A boot highly specialized for one task may be ill-suited for another. Gear with extreme chemical resistance might not have the best traction for uneven terrain, just as a heavily insulated boot would be unsafe and uncomfortable in a high-heat environment.

The Role of Removable Insoles

This feature directly addresses the comfort trade-off. Removable insoles allow you to customize the fit and support of your gear with aftermarket or orthopedic inserts without compromising its core protective qualities. This is a simple but effective way to improve long-term wearability.

How to Select the Right Features for Your Environment

Your choice should be dictated entirely by the known, consistent hazards of your workplace. Use this checklist to prioritize your needs.

- If your primary risk is electrical circuits: Prioritize gear with a clear Electrical Hazard (EH) rating and ensure it is kept dry and in good condition.

- If your primary risk is sharp ground debris: Puncture resistance is non-negotiable, and it is almost always paired with a protective safety toe.

- If your primary risk is water or liquid exposure: Accurately determine if you need water resistance for light splashes or full waterproofing for saturation.

- If your primary risk is extreme temperatures: Select gear with specific insulation (for cold) or heat-resistant outsoles (for hot surfaces) as your top priority.

- If your primary risk is hazardous liquids: Chemical resistance is paramount; verify the gear is rated for the specific chemicals you handle.

By systematically matching protective features to documented hazards, you ensure your gear provides optimal safety without sacrificing essential function.

Summary Table:

| Hazard Type | Key Protective Features | Ideal For |

|---|---|---|

| Electrical Currents | EH-rated, non-conductive materials | Electricians, maintenance crews |

| Water/Liquids | Waterproof/water-resistant membranes | Outdoor, marine, or wet environments |

| Extreme Cold | Insulation for heat retention | Cold storage, winter construction |

| Extreme Heat | Heat-resistant outsoles | Welding, paving, foundry work |

| Sharp Debris | Puncture-resistant plate (steel/composite) | Construction, demolition, waste management |

| Chemical Exposure | Chemical-resistant materials | Labs, industrial plants, agriculture |

Need to equip your team with precisely engineered safety footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of specialized boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities cover all types of protective footwear—from EH-rated and waterproof to insulated and puncture-resistant—ensuring your workforce is safe and productive in any environment. Contact us today for a custom solution tailored to your specific hazards.

Visual Guide

Related Products

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What does puncture resistance in ASTM standards involve? Your Guide to ASTM PR Footwear Safety

- How does toe box design differ between men's and women's work boots? Fit for a Woman's Foot Anatomy

- What is puncture resistance in safety footwear? Your Guide to Essential Foot Protection

- What other workplace hazards are denoted on safety toe boots? Decode the EH, Mt, and SD markings.