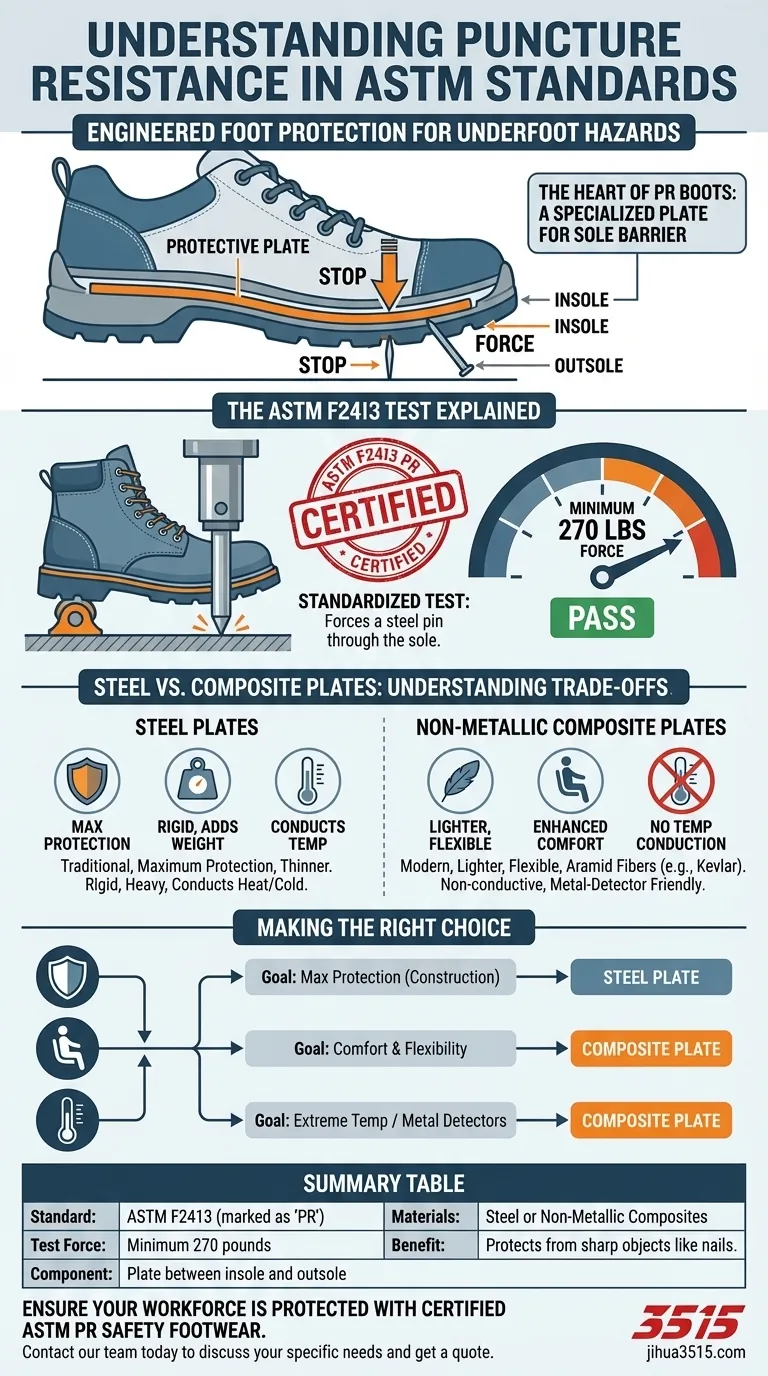

In the context of ASTM standards, puncture resistance refers to a specific safety feature in footwear designed to protect the foot from sharp objects penetrating the sole. This is achieved by incorporating a durable, puncture-resistant plate between the insole and outsole that can withstand significant force from hazards like nails or metal shards.

The core principle of ASTM-rated puncture resistance is not just about using a tough material, but about meeting a specific, measurable performance standard through a standardized test that simulates a common workplace hazard.

How Puncture Resistance is Engineered

A boot's ability to resist punctures isn't an accident of its design; it's an intentional engineering feature focused on a single protective layer.

The Protective Plate

The heart of any puncture-resistant boot is a specialized plate. This component is positioned directly above the main outsole.

This plate is the sole barrier responsible for stopping a sharp object before it can reach your foot.

The Role of the ASTM Standard

The relevant standard is ASTM F2413. Footwear that meets this requirement is explicitly marked with "PR" (Puncture Resistant).

This designation certifies that the boot has passed a specific laboratory test, ensuring it provides a reliable level of protection against underfoot threats.

The ASTM Puncture Resistance Test Explained

To earn the PR rating, a boot must withstand a precise and demanding test. This ensures consistent and trustworthy protection across all certified footwear.

The Test Method

The test involves forcing a standardized, sharp steel pin through the sole of the boot with a high degree of force.

The Performance Requirement

The protective plate must withstand a minimum of 270 pounds of force without being fully penetrated by the test pin. This simulates the real-world pressure of stepping directly onto a nail or other sharp object.

Understanding the Trade-offs: Steel vs. Composite Plates

The material used for the protective plate impacts the boot's weight, flexibility, and comfort. The two primary options are steel and non-metallic composites.

Steel Plates

Steel is the traditional material for puncture resistance. It offers maximum protection and is often thinner than composite alternatives.

However, steel is rigid, adds weight, and conducts heat and cold, which can be a significant drawback in extreme temperature environments.

Non-Metallic Composite Plates

Modern boots often use composite plates made from materials like Aramid fibers (e.g., Kevlar). These plates are lighter, much more flexible, and do not conduct temperature.

This increases comfort, especially for workers who spend long hours on their feet or who must bend and crouch frequently. They are also ideal for environments where metal detectors are used.

Making the Right Choice for Your Goal

Selecting the right type of puncture-resistant boot depends entirely on your work environment and daily tasks.

- If your primary focus is maximum protection in a construction or demolition zone: A boot with a steel plate provides proven, rigid defense against the largest hazards.

- If your primary focus is all-day comfort and flexibility: A composite plate offers certified protection while reducing fatigue and improving maneuverability.

- If you work in extreme hot or cold conditions: A composite plate is essential, as it will not transfer uncomfortable temperatures to your foot.

- If you work in a high-security environment with metal detectors: A non-metallic composite plate is the only practical option.

Ultimately, ensuring your footwear carries the ASTM "PR" rating is the critical first step in protecting yourself from underfoot hazards.

Summary Table:

| Feature | Details |

|---|---|

| Standard | ASTM F2413 (marked as 'PR') |

| Test Force | Minimum 270 pounds |

| Protective Component | Plate between insole and outsole |

| Common Plate Materials | Steel or Non-Metallic Composites (e.g., Aramid fibers) |

| Key Benefit | Protects foot from penetration by sharp objects like nails. |

Ensure your workforce is protected with certified ASTM PR safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of puncture-resistant boots for distributors, brand owners, and bulk clients. Whether you need the maximum protection of steel or the lightweight comfort of composite plates, our production capabilities deliver reliable, certified safety. Contact our team today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What is molded or direct attach construction in work boots? A Guide to Superior Durability & Water Resistance

- What are some characteristics of top-performing oil field boot brands? Built for Safety, Durability & Comfort

- What should be considered regarding the sole design and material of work boots? Maximize Safety & Comfort

- How does the leather of packer boots change over time? A Guide to Developing a Rich Patina

- Why are high-durability work boots essential for stone cutting? Protect Operators from High-Velocity Shards

- In what work environments are soft-toe boots most suitable? Prioritize Comfort and Agility for Light-Duty Work

- What are the key components to look for in durable, quality boots? Invest in Footwear Built to Last

- What factors should be considered when choosing work shoes? The Ultimate Guide to Safety & Comfort