At the core of any safety shoe's defense against workplace hazards are its protective toe caps. These reinforced components, typically made from steel, alloy, or composite materials, are specifically engineered to withstand significant impact from falling objects and resist crushing forces from heavy equipment, preventing catastrophic foot injuries.

The essential feature for impact and compression protection is the safety toe cap. However, the choice of material—steel, alloy, or composite—involves critical trade-offs in weight, conductivity, and comfort that determine the right shoe for a specific environment.

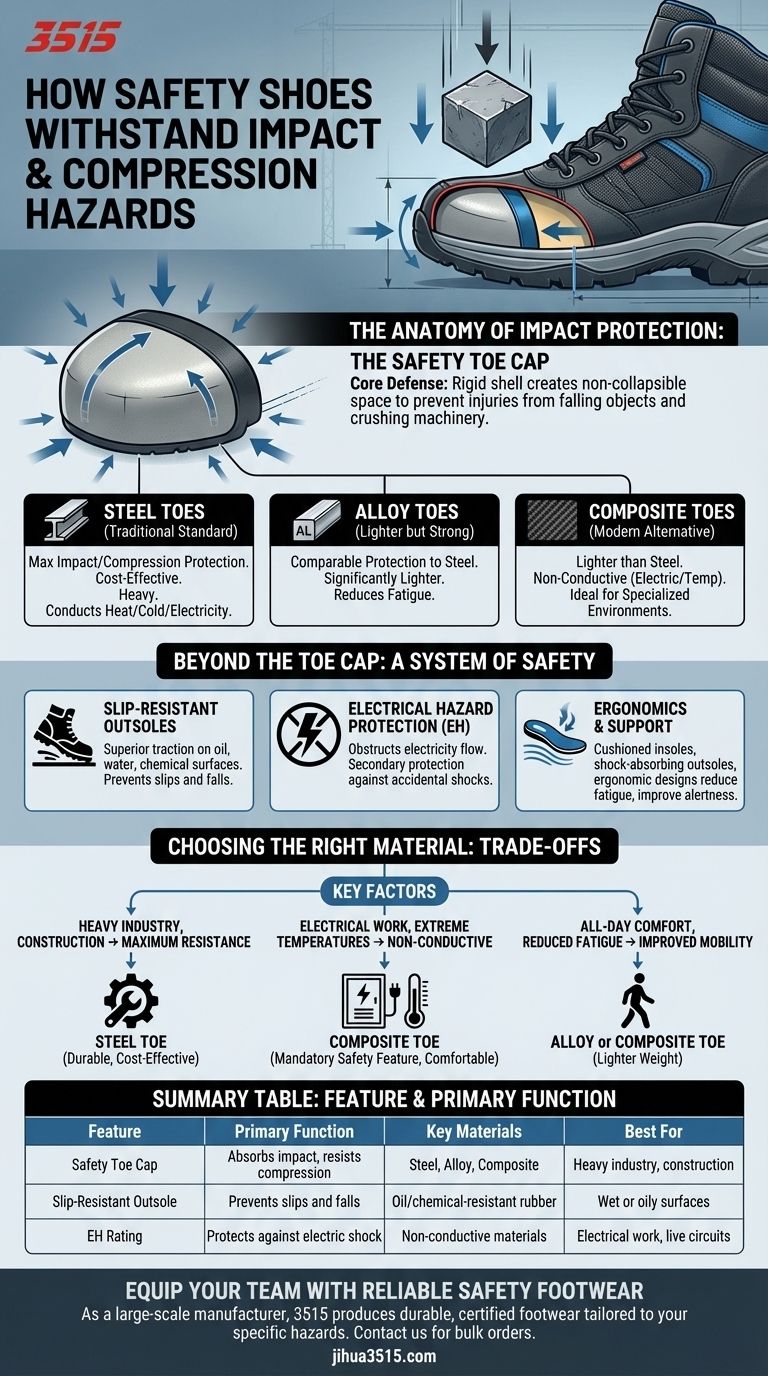

The Anatomy of Impact Protection: The Safety Toe Cap

The safety toe is the single most important component for shielding your feet from impact and compression. It acts as a rigid, protective shell integrated into the front of the shoe.

The Fundamental Role

A safety toe is designed to create a non-collapsible space around your toes. When a heavy object falls or a piece of machinery rolls over the foot, this cap distributes the force and prevents the front of the shoe from caving in.

Steel Toes: The Traditional Standard

Steel is the original material for safety toes. It offers an exceptionally high level of protection against impact and compression and is often the most cost-effective option.

Alloy Toes: Lighter but Strong

Materials like aluminum are used to create alloy toes. These provide comparable protection to steel but are significantly lighter, which helps reduce foot fatigue over a long workday.

Composite Toes: The Modern Alternative

Composite toes are made from non-metal materials like thermoplastics, carbon fiber, or Kevlar. They are much lighter than steel and do not conduct electricity or heat, making them ideal for certain specialized environments.

Beyond the Toe Cap: A System of Safety

While the toe cap handles direct impact, a truly effective safety shoe incorporates other features that contribute to overall protection and prevent accidents in the first place.

Slip-Resistant Outsoles

The sole of a safety shoe is critical. Durable outsoles made from materials resistant to oil, water, and chemicals provide superior traction, which is crucial for preventing slips and falls on hazardous surfaces.

Electrical Hazard Protection

Many safety shoes are rated for Electrical Hazard (EH) protection. This means their construction and materials are designed to obstruct the flow of electricity, offering a secondary source of protection against accidental shocks.

Ergonomics and Support

Safety is also about endurance. Cushioned insoles, shock-absorbing outsoles, and ergonomic designs ensure comfort during long hours. A comfortable worker is less fatigued and therefore more alert and less prone to accidents.

Understanding the Trade-offs

Choosing the right safety toe material is not just about protection; it's about balancing key factors specific to your job.

Weight vs. Fatigue

Steel is the heaviest option, which can lead to greater fatigue by the end of a shift. Lighter composite and alloy toes can make a noticeable difference in all-day comfort and mobility.

Conductivity and Environment

If you work around live electrical circuits, a non-metallic composite toe is a mandatory safety feature. Likewise, because steel readily conducts temperature, composite toes are far more comfortable in extremely hot or cold conditions.

Bulk and Fit

To achieve the same safety rating as steel, a composite toe cap may need to be slightly thicker or bulkier. This can sometimes affect the overall profile and fit of the shoe, making it important to try them on.

Making the Right Choice for Your Workplace

Your specific hazard environment and daily tasks should dictate your choice of safety footwear.

- If your primary focus is maximum impact resistance in heavy industry: A steel toe shoe often provides the highest level of protection and is a durable, cost-effective choice.

- If your primary focus is working around electricity or in extreme temperatures: A non-conductive composite toe is the essential choice for your safety and comfort.

- If your primary focus is all-day comfort and reducing fatigue: Lighter-weight alloy or composite toes can significantly decrease strain and improve mobility.

Choosing the right safety shoe is about matching its specific protective technology to the precise risks of your job.

Summary Table:

| Feature | Primary Function | Key Materials | Best For |

|---|---|---|---|

| Safety Toe Cap | Absorbs impact, resists compression | Steel, Alloy, Composite | Heavy industry, construction |

| Slip-Resistant Outsole | Prevents slips and falls | Oil/chemical-resistant rubber | Wet or oily surfaces |

| Electrical Hazard (EH) Rating | Protects against electric shock | Non-conductive materials | Electrical work, live circuits |

Need to equip your team with reliable safety footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, certified footwear tailored to your specific workplace hazards—from steel and composite toes to EH-rated designs. Contact us today to discuss your bulk order requirements and protect your workforce with quality you can trust.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What industries besides construction require durable and protective footwear for women? Key Sectors Explained

- Do firefighter boot standards vary by region or country? Navigating NFPA, EN, and AS/NZS Standards

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How does an industrial-grade zipper strength testing machine ensure the reliability of fire safety boot fastening systems?

- How does data augmentation technology improve the detection of safety shoes? Enhancing AI for Factory Worksite Safety

- What is puncture resistance in safety footwear? Your Guide to Essential Foot Protection

- What are safety shoes and what is their primary purpose? Essential PPE for Workplace Foot Protection

- How does a PPE database optimize specialty protective shoe supply chains? Enhance Forecasting and Reduce Costs