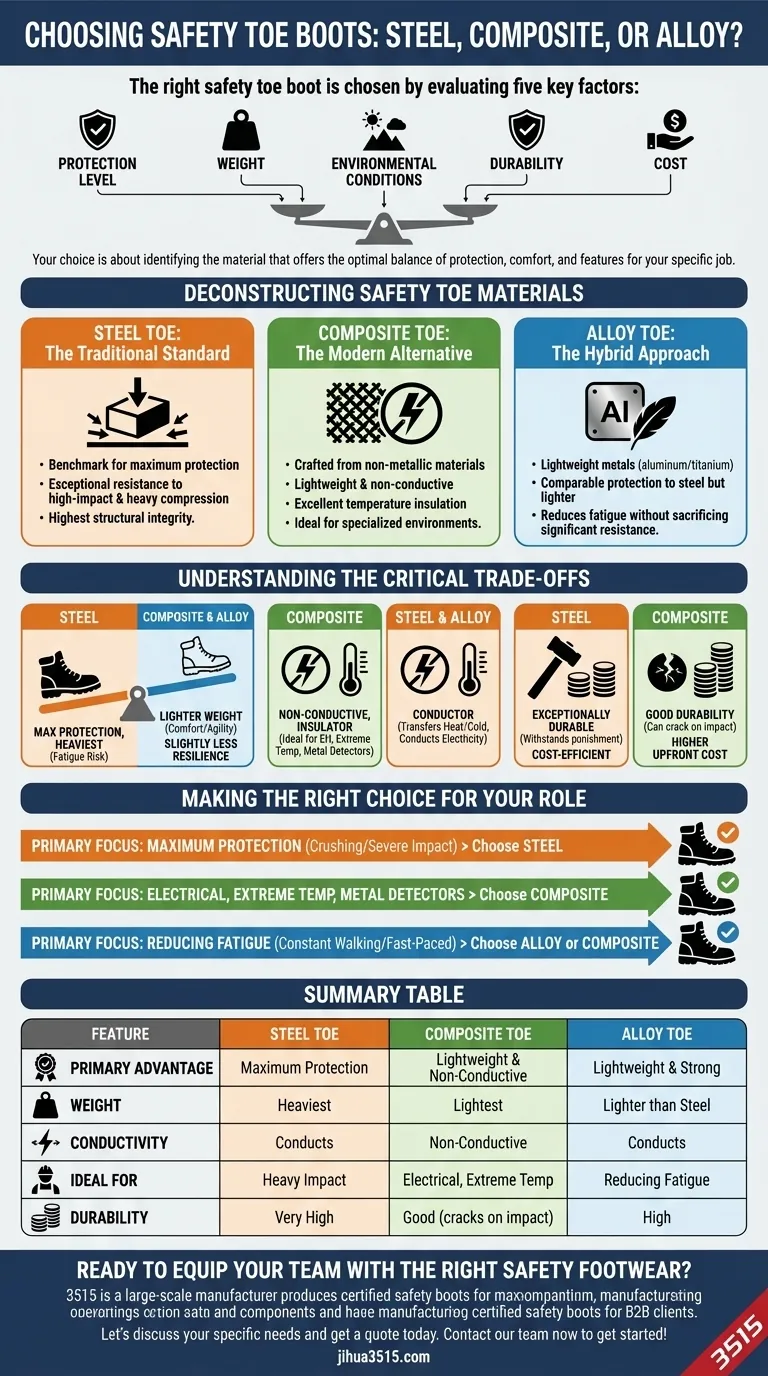

The right safety toe boot is chosen by systematically evaluating five key factors: protection level, weight, environmental conditions, durability, and cost. While all certified safety toes meet foundational impact standards, the material you choose—steel, composite, or alloy—directly affects your daily comfort, safety in specific situations, and long-term value.

Your choice isn't about finding the single "best" material, but about identifying the material that offers the optimal balance of protection, comfort, and features for your specific job and work environment.

Deconstructing the Safety Toe Materials

Each material presents a distinct profile of strengths and weaknesses. Understanding these profiles is the first step in making an informed decision.

Steel Toe: The Traditional Standard

Steel is the original material for safety toes and remains the benchmark for maximum protection. It is a simple, effective, and often cost-efficient solution.

These caps are known for their exceptional resistance to high-impact and heavy compression forces. If a heavy object falls or rolls onto the foot, steel provides the highest level of structural integrity.

Composite Toe: The Modern Alternative

Composite toes are crafted from non-metallic materials like carbon fiber, fiberglass, or Kevlar. They are engineered to meet the same safety standards as steel but with different properties.

Their primary advantages are being lightweight and non-conductive. They do not transfer heat or cold and will not conduct electricity, making them ideal for certain specialized environments.

Alloy Toe: The Hybrid Approach

Alloy toes are made from lightweight metals such as aluminum or titanium. They represent a middle ground between the brute strength of steel and the lightweight nature of composite.

These caps offer protection comparable to steel but in a lighter, less bulky package. This makes them a popular choice for those seeking to reduce fatigue without significantly compromising on impact resistance.

Understanding the Critical Trade-offs

Selecting the right boot requires balancing competing priorities. What you gain in one area, you often sacrifice in another.

Protection vs. Weight

The most fundamental trade-off is between maximum protection and all-day comfort.

Steel offers the highest level of protection against impact and compression but is also the heaviest option, which can lead to fatigue over a long shift.

Composite and alloy toes significantly reduce the boot's weight, enhancing comfort and agility, but may offer slightly less resilience than steel under extreme compression loads.

Environmental Factors: Conductivity

Your work environment can immediately rule out certain materials.

Steel is a conductor. It will readily transfer cold or heat to your feet and will conduct electricity, making it unsuitable for certain electrical hazard (EH) rated work.

Composite is a complete insulator. It provides excellent protection from temperature transfer and is the only choice for electricians or anyone working in a high-voltage environment. It also won't set off metal detectors.

Durability and Cost

Durability isn't just about impact resistance; it's also about withstanding daily wear and tear.

Steel is exceptionally durable and can withstand more punishment over time. However, once a composite toe takes a significant impact, the material can crack, and the boot must be replaced.

Generally, composite toe boots carry a higher upfront cost due to the more advanced materials and manufacturing process involved.

Making the Right Choice for Your Role

Use your primary daily need as your guide to select the best material for your situation.

- If your primary focus is maximum protection against crushing weight or severe impact: Choose steel for its unparalleled compressive strength and durability.

- If your primary focus is working around electricity, extreme temperatures, or metal detectors: Choose composite for its essential non-conductive and non-metallic properties.

- If your primary focus is reducing fatigue from constant walking or fast-paced work: Choose alloy or composite to gain a significant weight advantage over steel.

By aligning the material's core strengths with your job's specific demands, you ensure your safety footwear is an asset, not a burden.

Summary Table:

| Feature | Steel Toe | Composite Toe | Alloy Toe |

|---|---|---|---|

| Primary Advantage | Maximum Protection | Lightweight & Non-Conductive | Lightweight & Strong |

| Weight | Heaviest | Lightest | Lighter than Steel |

| Conductivity | Conducts Heat/Cold & Electricity | Non-Conductive | Conducts Heat/Cold & Electricity |

| Ideal For | Heavy Impact/Crushing Hazards | Electrical Work, Extreme Temperatures | Reducing Fatigue, Fast-Paced Work |

| Durability | Very High | Good (can crack on impact) | High |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. We have the expertise and production capabilities to deliver the perfect balance of protection, comfort, and value—whether you need steel, composite, or alloy toe boots.

Let's discuss your specific needs and get a quote today.

Contact our team now to get started!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job