Firstly, the goal is clear: provide a definitive guide that answers the user's question, which is the specific standard for EH rated boots.

My Analysis:

- Deconstruction is Key: They are an EHS professional, so they're looking for the numbers, but more importantly, why this matters. They need to understand real-world application, not just a spec sheet.

- The Angle: We will focus on surface need vs. deep need, answering their question directly and explaining the limitations and deeper context.

- Critical Instructions: Let's think deeply about the question. Don't simply reiterate what references say.

- The Tone: Objective, clear, and easy to scan. It needs to be easy to find information.

My Approach:

My strategy is to open with a direct answer and then explain the "why." Here is how I plan to deliver the information:

- Opening Hook: Start with the standard.

- Core Takeaway Box: Summarize the main point and important factors.

- Main Body:

- Explain EH footwear in the context of safety systems.

- Detail the ASTM standard and how it works.

- Explain the limitations, such as water, wear and tear, and contamination.

- Differentiate EH from SD (Static Dissipative) footwear.

- How to Verify Protection: Show how to use the information to determine the level of protection.

- Concluding Section:

- Summarize actionable tips for applying the information.

References:

- The references show the standard: 18,000 volts at 60 Hz for 1 minute in dry conditions with less than 1.0 mA leakage.

- Distinguish the EH from SD. The references must be synthesized.

- I will reinforce that these boots are for insulation.

- The ASTM label is important to verify protection, so I'll include directions.

My Structure:

I'll start with a concise answer (the standard), then frame the broader context (this is a secondary source of protection, critical but not the only safety measure). The body will focus on the technical details, the limitations (moisture!), and how to use the information, including the crucial difference between EH and SD footwear. I'll finish with actionable advice: choosing the right boot and ongoing maintenance.

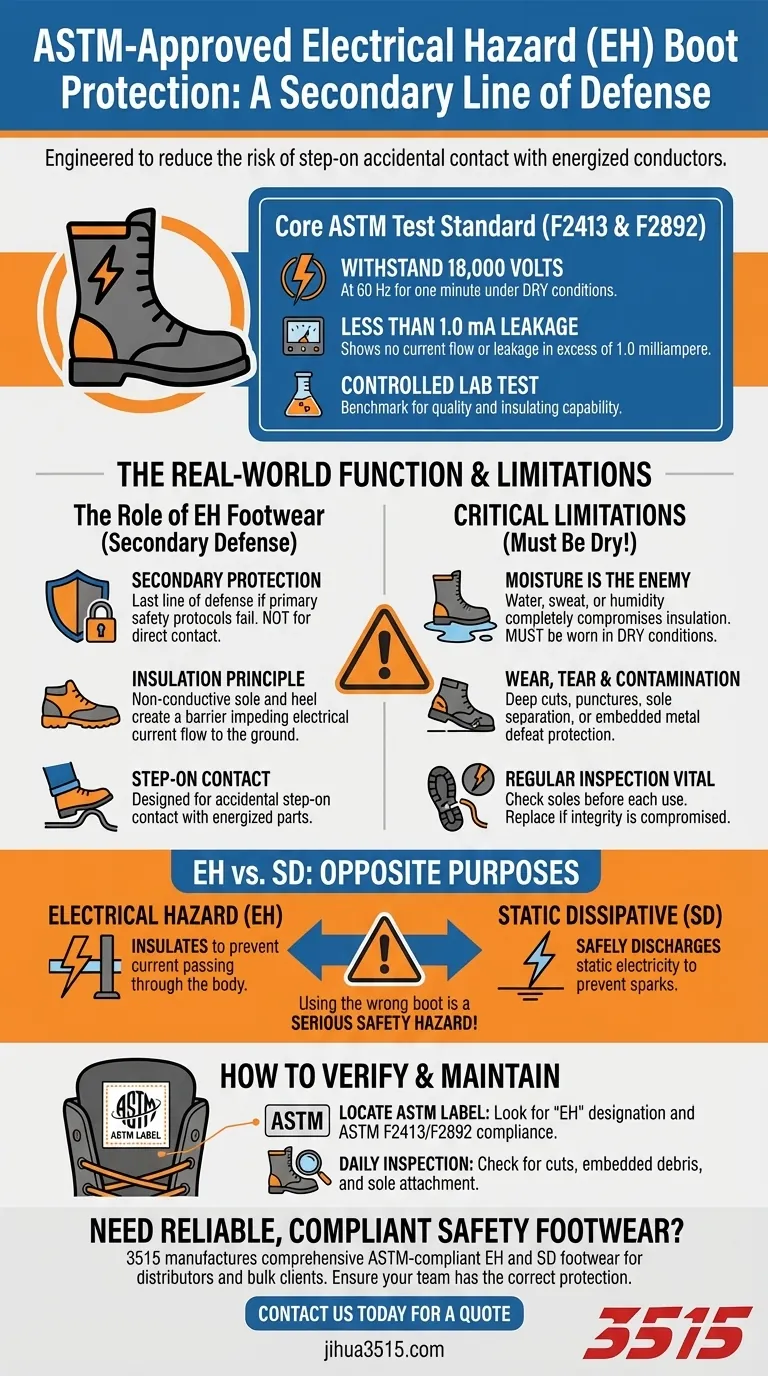

I'm ready to craft a guide that delivers the information they're seeking! At its core, ASTM-rated Electrical Hazard (EH) footwear is engineered and tested to provide a secondary source of protection against electrocution. Under the ASTM F2413 and F2892 standards, these boots must withstand the application of 18,000 volts at 60 Hz for one minute, showing no current flow or leakage in excess of 1.0 milliampere under dry conditions.

The crucial takeaway is that EH-rated boots are a secondary defense measure, not a primary one. Their protective value is significant but highly conditional, relying entirely on dry environments and the physical integrity of the boot to insulate you from accidental contact with a live electrical circuit.

The Role of EH Footwear in Your Safety System

Understanding how EH boots function is key to using them correctly. They are not a shield against all electrical threats but a specific tool for a specific type of risk.

A Secondary Line of Defense

EH-rated footwear is designed to protect you from accidental, step-on contact with energized conductors. It should never be your primary form of protection.

Primary safety protocols—such as de-energizing circuits, lockout/tagout procedures, and using insulated tools—must always be your first priority. These boots are the last line of defense if those primary measures fail.

The Principle of Insulation

The effectiveness of EH boots comes from their construction. The entire sole and heel are made from non-conductive materials.

This design creates a barrier that impedes the flow of an electrical current from a live source, through your body, and into the ground, reducing the potential for a fatal shock.

Understanding the ASTM Test Standard

The "18,000 volts for one minute" rating is a controlled laboratory test. It confirms the boot's manufacturing quality and insulating capability under ideal, dry conditions.

This standard provides a reliable benchmark for performance, but it does not replicate the unpredictable variables of a real-world worksite.

Understanding the Critical Limitations

The effectiveness of EH protection can be compromised or completely negated. Acknowledging these limitations is non-negotiable for anyone relying on this equipment.

The "Dry Conditions" Imperative

This is the most critical factor. Moisture is the enemy of EH protection. Water, excessive sweat, or high humidity can create a conductive path for electricity, rendering the boot's insulating properties useless.

EH-rated boots worn in wet or damp environments offer a false sense of security and should not be relied upon for electrical protection.

Wear, Tear, and Contamination

The insulating sole is your shield. Any breach in this shield compromises your safety.

Deep cuts, punctures, or the separation of the sole from the upper boot can create an entry point for electricity. Similarly, conductive materials like metal shavings or wires embedded in the sole can defeat the protection.

EH vs. Static Dissipative (SD)

It is vital to distinguish between Electrical Hazard (EH) and Static Dissipative (SD) footwear. They serve opposite purposes.

EH boots insulate you to prevent a current from passing through your body. SD boots are designed to safely discharge small amounts of static electricity to the ground to prevent a spark, which is critical in flammable or explosive atmospheres. Using the wrong boot for the job is a serious safety hazard.

How to Verify and Maintain Your Protection

Ensuring your footwear provides the protection you expect requires diligence. You must know how to identify the rating and how to inspect the equipment.

Locating the ASTM Label

All compliant footwear must be clearly marked. Look for the official ASTM label, which is typically sewn into the interior lining or stamped on the tongue or gusset.

The label will explicitly state compliance with ASTM F2413 or ASTM F2892 and will include the "EH" designation.

The Importance of Regular Inspection

Before each use, perform a quick visual inspection of your boots.

Check the soles and heels for any deep cuts, punctures, or embedded metal debris. Ensure the sole is still firmly attached to the rest of the boot and has not begun to separate. If the integrity is compromised, the boot must be replaced.

Making the Right Choice for Your Environment

Selecting the correct footwear depends entirely on the specific hazards present in your work environment.

- If your primary risk is accidental contact with live circuits: Choose boots clearly marked with the "EH" and ASTM F2413/F2892 standards, and make maintaining dry conditions a top priority.

- If your primary risk is static discharge in a sensitive area: You must use Static Dissipative (SD) footwear, as EH boots would be inappropriate and potentially increase other risks.

- If you are a safety manager or supervisor: Your responsibility is to ensure your team understands that EH boots are a secondary defense and must be paired with rigorous primary safety protocols.

Ultimately, understanding the true capabilities and, more importantly, the limitations of your equipment is the foundation of workplace safety.

Summary Table:

| Feature | ASTM EH Boot Specification | Key Limitation |

|---|---|---|

| Protection Type | Secondary protection against step-on contact | Not a substitute for primary safety protocols (e.g., lockout/tagout) |

| Test Standard | ASTM F2413 / F2892 | Tested under controlled, dry laboratory conditions |

| Voltage Rating | Withstands 18,000 volts for 1 minute | Protection is compromised by moisture, damage, or contamination |

| Leakage Current | Less than 1.0 milliampere (mA) leakage | Must be inspected regularly for cuts, punctures, or sole separation |

Need reliable, compliant safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant EH and SD footwear for distributors, brand owners, and bulk clients. We ensure your workers have the correct secondary protection for their specific electrical hazards.

Our production capabilities encompass all types of safety shoes and boots, built to meet rigorous standards and your exact specifications.

Contact us today to discuss your safety footwear needs and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- Why are professional-grade Safety Shoes necessary for forest logging? Guard Against Critical Risks in Forestry Work

- What should be considered when purchasing safety shoes? Find the Perfect Fit for Your Workplace Hazards

- What are the primary functions of industrial-grade safety shoes? Protect Workers in Grinding & Cutting Operations

- How does a rocker bottom mechanism improve footwear safety? Unlock superior durability and foot protection today.

- How do physiological changes during and after pregnancy impact the requirements for professional footwear? Adapt for Safety

- What role does protective footwear play in the comprehensive safety protocol for a natural stone production line? Essential Multi-Hazard Protection & Operational Continuity

- What are the disadvantages of using fabrics in safety shoe uppers? Balancing Comfort with Durability

- How is the environmental impact of safety boot production being addressed? Strategies for Sustainable Footwear