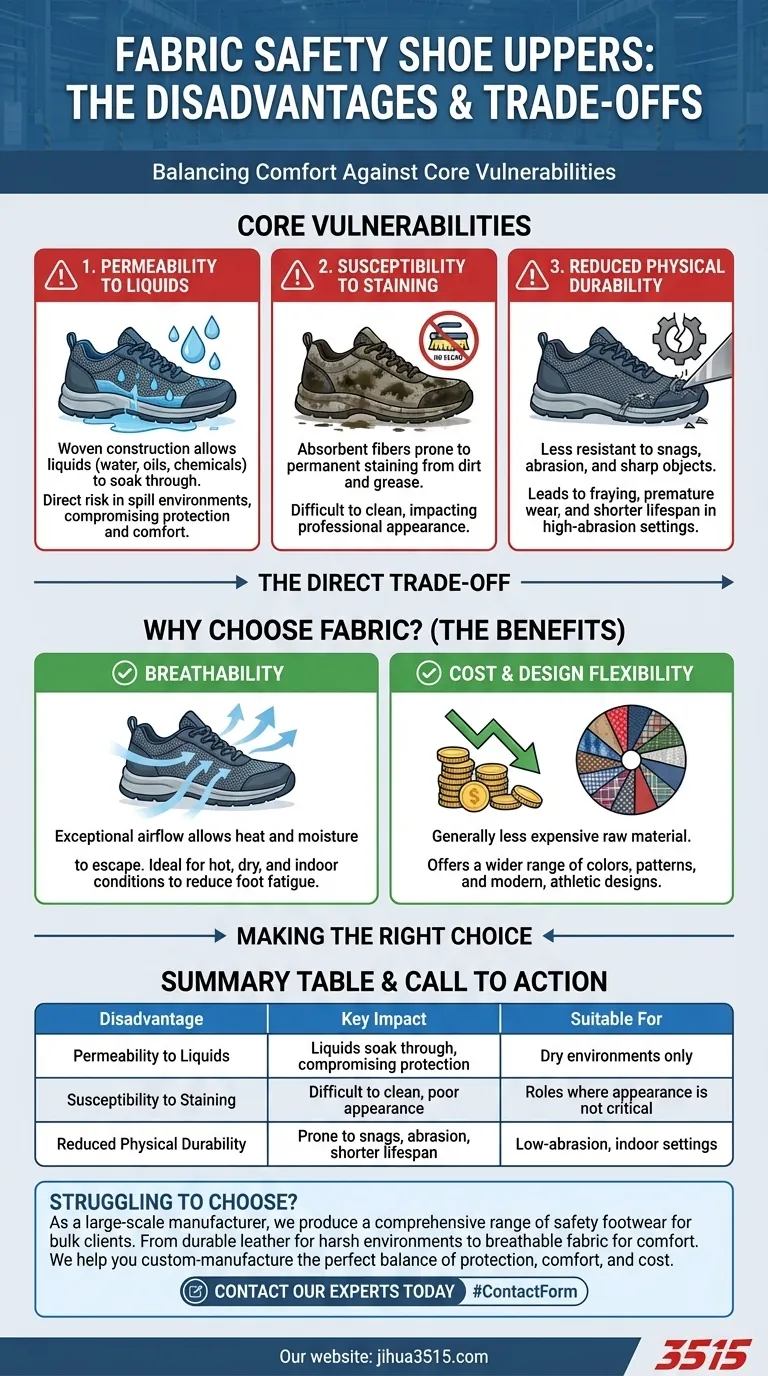

While offering significant comfort advantages, fabric uppers on safety shoes present three primary disadvantages rooted in their material structure. They are not impermeable to liquids, they stain easily, and their woven surface makes them more susceptible to physical damage like snags and abrasion compared to solid materials.

The decision to use a fabric upper is a direct trade-off, balancing breathability and lower cost against robust protection from liquids, stains, and physical wear. Your specific work environment is the single most important factor in determining if this trade-off is acceptable.

The Core Vulnerabilities of Fabric Uppers

Understanding the inherent weaknesses of woven materials is key to evaluating their suitability for a safety-critical application. These issues stem directly from the porous and pliable nature of the fabric itself.

Permeability to Liquids

Unlike leather or synthetic polymers, fabrics are not naturally waterproof. Their woven construction allows liquids—from water to oils and chemical splashes—to soak through to the foot.

This poses a direct risk in environments with spill hazards, compromising not only comfort but also the protective barrier your footwear is meant to provide.

Susceptibility to Staining

The absorbent nature of fabric fibers makes them prone to staining from dirt, grease, and other workplace contaminants.

While this may seem like a purely aesthetic issue, it can be a significant drawback in roles requiring a clean, professional appearance. It also makes the footwear much more difficult to clean and maintain.

Reduced Physical Durability

The surface of a woven fabric is inherently less resistant to certain types of damage than a solid material.

Sharp corners, rough surfaces, and daily scuffs can easily snag the fibers, leading to fraying and premature wear. In high-abrasion environments, fabric uppers will typically have a much shorter lifespan.

Understanding the Trade-offs: Why Choose Fabric at All?

Despite these disadvantages, fabric uppers are popular for valid reasons. Recognizing their strengths provides a complete picture for making an informed decision.

The Benefit of Breathability

Fabric's primary advantage is its exceptional breathability. The porous structure that allows liquids in also allows heat and moisture vapor (sweat) to escape.

This makes fabric-upper safety shoes significantly more comfortable in hot, dry conditions or during long periods of indoor work, reducing foot fatigue.

Cost and Design Flexibility

Generally, fabric is a less expensive raw material than high-quality leather. This cost savings is often passed on to the consumer.

Furthermore, fabrics can be produced in a vast range of colors, patterns, and weaves, allowing for more modern, athletic-style designs than traditional safety footwear.

Making the Right Choice for Your Environment

Your daily tasks and work conditions should be the ultimate guide in your selection.

- If your primary focus is protection in wet, dirty, or high-abrasion environments: Fabric uppers are a poor choice, and a more robust material like leather or a coated synthetic is necessary.

- If your primary focus is comfort and airflow in a clean, dry, and low-risk environment: The breathability and lower cost of fabric uppers make them an excellent and practical option.

Matching the footwear's material properties to your daily hazards is the most effective way to ensure both safety and long-term value.

Summary Table:

| Disadvantage | Key Impact | Suitable For |

|---|---|---|

| Permeability to Liquids | Liquids soak through, compromising protection | Dry environments only |

| Susceptibility to Staining | Difficult to clean, poor appearance | Roles where appearance is not critical |

| Reduced Physical Durability | Prone to snags, abrasion, shorter lifespan | Low-abrasion, indoor settings |

Struggling to choose the right safety shoe material for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, from durable leather options for harsh environments to breathable fabric designs for comfort in low-risk settings.

We can help you select or custom-manufacture the perfect safety shoes that balance protection, comfort, and cost-effectiveness for your specific operational hazards.

Contact our experts today for a consultation and get the right footwear solution for your team.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data