In short, a "non-marking" feature on a tactical work boot means its outsole is engineered from a specialized rubber compound that will not leave scuff marks, smudges, or residue on surfaces. This capability is verified against specific performance standards, such as the military specification MIL-S-22777, ensuring the boot leaves no visible trace, even when weathered from use.

The core purpose of a non-marking sole extends beyond simple cleanliness. In a tactical context, it is a functional requirement for maintaining stealth, preserving the integrity of sensitive environments, and ensuring operational anonymity.

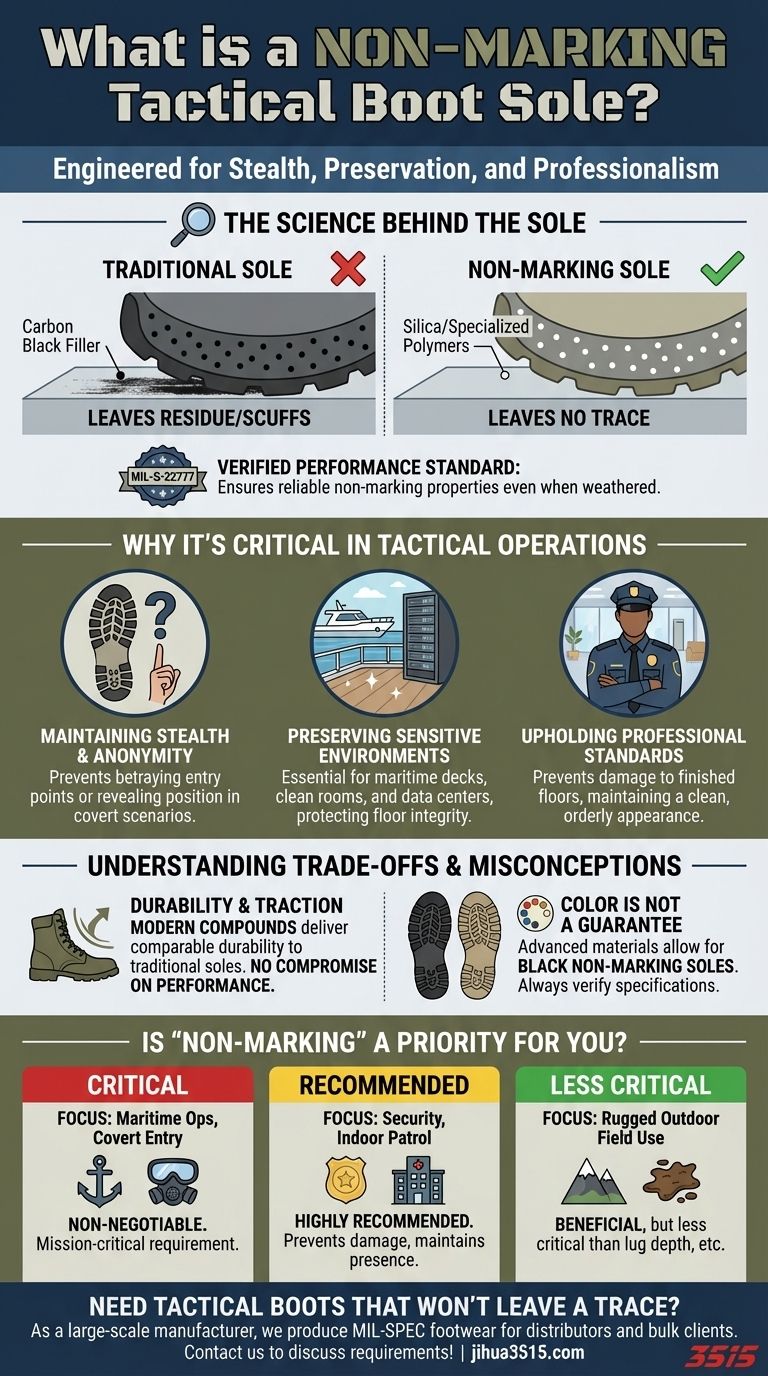

The Science Behind a Non-Marking Sole

To understand the value of this feature, it’s important to look at how it's achieved and what it signifies. It's not just a marketing term; it's a result of specific material engineering.

The Role of Material Composition

The key lies in the boot's outsole compound. Traditional black rubber soles often use carbon black as a reinforcing filler, which enhances durability but is the primary culprit for leaving black streaks and marks.

Non-marking soles use alternative fillers, such as silica, or are made from specialized synthetic rubber polymers that don't leach color or material onto surfaces when subjected to friction.

Meeting a Military Standard

The reference to MIL-S-22777 is significant. This military specification sets a clear, testable benchmark for performance.

When a boot complies with this standard, it means its non-marking properties have been verified to perform reliably in demanding conditions, making it a trusted feature for professional use.

Why This Feature is Critical in Tactical Operations

The ability to move without leaving a trace is not a trivial detail. For many operators, it is a core mission requirement.

Maintaining Stealth and Anonymity

In covert or law enforcement scenarios, leaving a scuff mark on a polished floor can betray a point of entry, reveal a position, or indicate that a secured area has been accessed. A non-marking sole eliminates this risk.

Preserving Sensitive Environments

This feature is critical in maritime operations on boat decks, where scuffs can damage expensive non-skid surfaces. It is also essential when operating in clean rooms, data centers, or any facility where floor integrity and cleanliness are paramount.

Upholding Professional Standards

For personnel working indoors, on finished floors, or in high-visibility security roles, non-marking soles are a matter of professionalism. They prevent damage to property and maintain a clean, orderly appearance.

Understanding the Trade-offs

While highly valuable, it's useful to understand the context of this feature. No single boot feature exists in a vacuum.

Durability and Traction

Historically, the softest compounds used for non-marking soles could wear slightly faster than the hardest carbon-black-filled rubbers. However, modern material science has largely closed this gap.

Today's premium non-marking outsoles deliver excellent durability and traction that is comparable to their marking counterparts, offering performance without compromise.

Color is Not a Guarantee

Do not assume a sole is non-marking based on its color. While many non-marking soles are lighter (tan, grey, or white), advanced compounds allow for black non-marking outsoles. Always verify the feature in the boot's official specifications.

Is "Non-Marking" a Priority for You?

Choosing the right boot means matching its features to your operational needs. Use these guidelines to decide how to prioritize this feature.

- If your primary focus is maritime operations or covert entry: A certified non-marking sole is a non-negotiable, mission-critical requirement.

- If your primary focus is security or indoor patrol on finished floors: This feature is highly recommended to prevent property damage and maintain a professional presence.

- If your primary focus is exclusively rugged outdoor or field use: While beneficial, a non-marking sole is less critical than features like lug depth, mud-shedding ability, and abrasion resistance.

Ultimately, choosing a boot with a non-marking sole is a deliberate decision to control your environmental signature.

Summary Table:

| Feature | Key Detail | Importance |

|---|---|---|

| Material Composition | Uses silica/specialized polymers instead of carbon black | Prevents scuff marks and residue |

| Performance Standard | Complies with MIL-S-22777 specification | Verified reliability in demanding conditions |

| Primary Benefit | Leaves no visible trace on surfaces | Critical for stealth and preserving sensitive areas |

| Ideal For | Covert ops, maritime, indoor security, clean rooms | Maintains operational anonymity and professionalism |

Need tactical boots that won't leave a trace? As a large-scale manufacturer, 3515 produces a comprehensive range of MIL-SPEC footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure your team gets boots with reliable non-marking soles and superior performance. Contact us today to discuss your requirements!

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the limitations of tactical boots? Understand the Trade-offs for Better Performance

- How do tactical duty boots affect physical performance? Balance Metabolic Cost & Gear Weight for Law Enforcement

- How does digital handgrip dynamometer data influence tactical footwear design for peak performance?

- How does boot comfort impact firefighter performance? Boost Endurance and Safety on the Fireground

- What fit considerations are important for tactical boots? The Ultimate Guide to Performance and Comfort

- Why is high-performance cushioning essential? Protect Joints and Boost Performance in Tactical Boots

- What are the different types of tactical boots available? Find the Right Boot for Your Mission

- What are the key differences between tactical boots and combat boots? Agility vs. Armor Explained