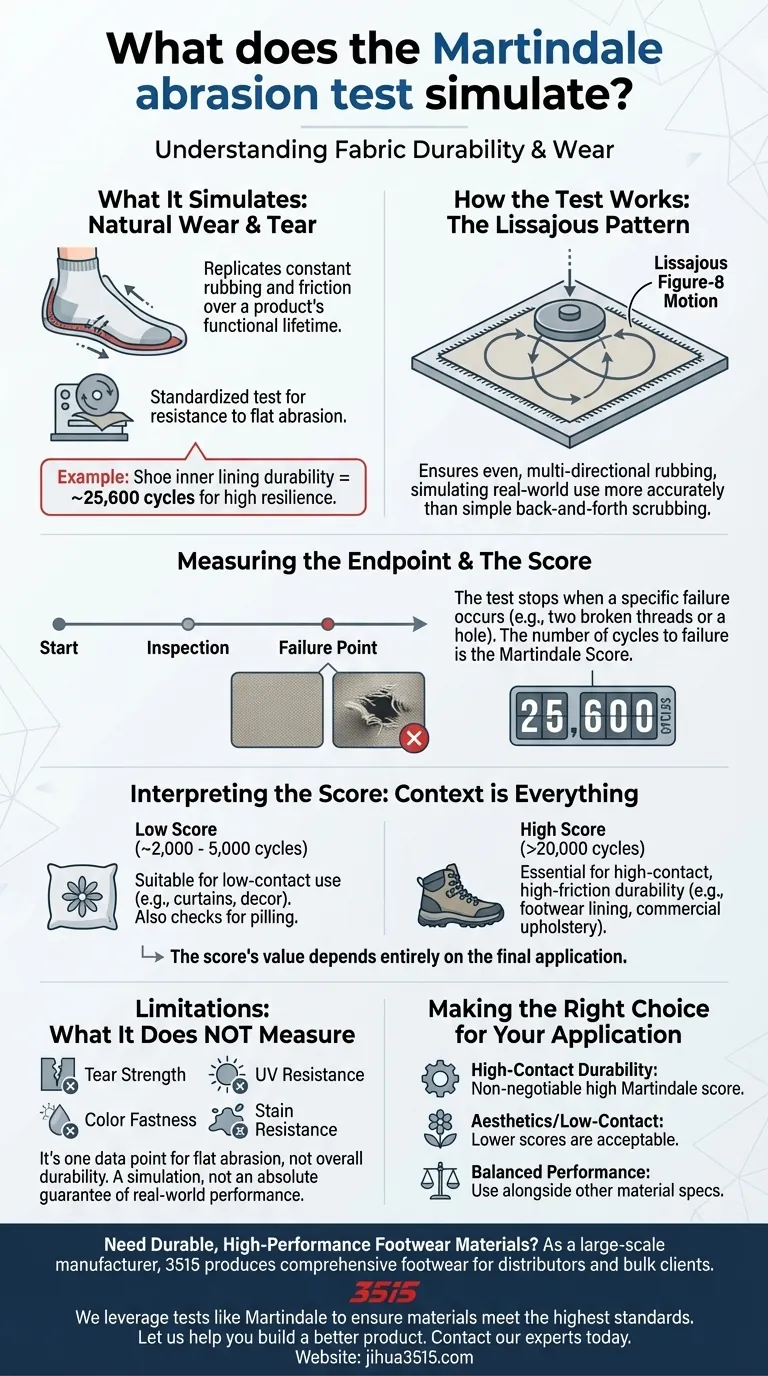

At its core, the Martindale abrasion test simulates the natural wear and tear a fabric endures from friction over its functional lifetime. For a product like a shoe, this test quantifies the durability of an inner lining by replicating the constant rubbing it experiences against a foot or sock, with a score of around 25,600 cycles indicating high resilience for prolonged use.

The Martindale test provides a standardized, objective score for a fabric's resistance to abrasion. This score is not just a measure of durability; it is a crucial data point for predicting a material's real-world performance and suitability for its intended application.

How the Martindale Test Works

To truly understand a material's score, you must first understand the mechanics of the test itself. It is a highly controlled and repeatable process designed to isolate one specific type of wear.

The Lissajous Pattern

The test material is mounted flat and rubbed by a smaller, weighted disc of a standard abradant fabric. The key is that this disc moves in a unique, seemingly random Lissajous pattern—a complex figure-8 motion.

This specific pattern is critical because it ensures the rubbing occurs evenly across all directions. This method is far more representative of real-world use than a simple back-and-forth scrub, which would only test the fabric's strength along one or two axes.

Measuring the Endpoint

The machine counts the number of cycles, or "rubs," the fabric endures. The test is stopped periodically for inspection.

The test's endpoint is defined by a specific point of failure. This is most often the breakage of two separate threads, but it can also be a noticeable change in appearance or the development of a hole.

The Martindale "Score"

The final result is the number of cycles the fabric successfully withstood before the designated point of failure was reached. This number is the Martindale score.

Interpreting the Martindale Score

A number like "25,600 cycles" is meaningless without context. The value of a score is entirely dependent on the product's final application.

Context is Everything

A score that is excellent for a decorative pillow would be completely inadequate for the inner lining of a performance hiking boot. The score of ~25,600 cycles mentioned for inner lining durability is indicative of a material designed for frequent, high-friction contact.

Pilling vs. Abrasion

The test can also be used to evaluate a fabric's tendency to pill—the formation of small, tangled balls of fiber on the surface. Pilling is often checked at a much lower cycle count (e.g., 2,000 to 5,000 cycles) as it is an earlier sign of wear than complete thread breakage.

Understanding the Trade-offs and Limitations

The Martindale test is an industry standard for a reason, but it is essential to recognize what it does not measure. Relying on it as the sole indicator of quality can be misleading.

Abrasion is Not Overall Durability

This test exclusively measures resistance to flat abrasion. It provides no information about other critical factors like:

- Tear Strength: How the fabric resists ripping.

- UV Resistance: How it holds up to sun exposure.

- Color Fastness: Whether the dye will rub off or fade.

- Stain Resistance: How it repels liquids and dirt.

A Simulation, Not Reality

While it is an excellent simulation, the test uses a standardized abradant under controlled pressure. It cannot perfectly replicate the infinite variables of real-world use, such as snagging on sharp objects or exposure to unique chemical environments. It is a powerful predictive tool, not an absolute guarantee.

Making the Right Choice for Your Application

Use the Martindale score as a vital piece of the puzzle, not the entire picture. Your final decision should be guided by the product's primary function.

- If your primary focus is high-contact durability (footwear lining, commercial upholstery, backpack fabric): A high Martindale score (typically >20,000) should be a non-negotiable requirement.

- If your primary focus is aesthetics or low-contact use (decorative textiles, curtains): A lower score is often perfectly acceptable and can be a more cost-effective choice.

- If your primary focus is balanced performance: Use the Martindale score as one key data point alongside other material specifications like tear strength, weight, and elemental resistance.

By understanding what the Martindale test truly measures—and what it doesn't—you can move beyond a simple number to make a truly informed decision about material performance.

Summary Table:

| Test Aspect | What It Simulates | Key Takeaway |

|---|---|---|

| Action | Constant, multi-directional rubbing (Lissajous pattern) | More realistic than simple back-and-forth motion. |

| Endpoint | Thread breakage or hole formation | Provides an objective score (e.g., 25,600 cycles). |

| Application | Suitability for high-friction use (e.g., shoe lining) | Score value is meaningless without context of the final product. |

| Limitations | Flat abrasion only; not tear strength or UV resistance | It's one critical data point, not a complete measure of durability. |

Need Durable, High-Performance Footwear Materials?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We understand that material durability is paramount. Our production capabilities encompass all types of shoes and boots, and we leverage tests like Martindale to ensure the materials we use meet the highest standards for your specific application.

Let us help you build a better product. Contact our experts today to discuss your material requirements and how we can deliver lasting quality for your customers.

Visual Guide

Related Products

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What should someone do if they are unsure whether their injury requires a walking boot? Seek Expert Medical Advice

- Is safety toe better than steel toe? A Guide to Choosing the Right Protection

- Is there a downside to steel toe boots? Weighing Protection Against Daily Comfort

- How can maintaining a positive attitude help when wearing a walking boot? Turn Recovery into a Positive Journey

- When should you seek immediate medical care while wearing a walking boot? Recognize Critical Warning Signs