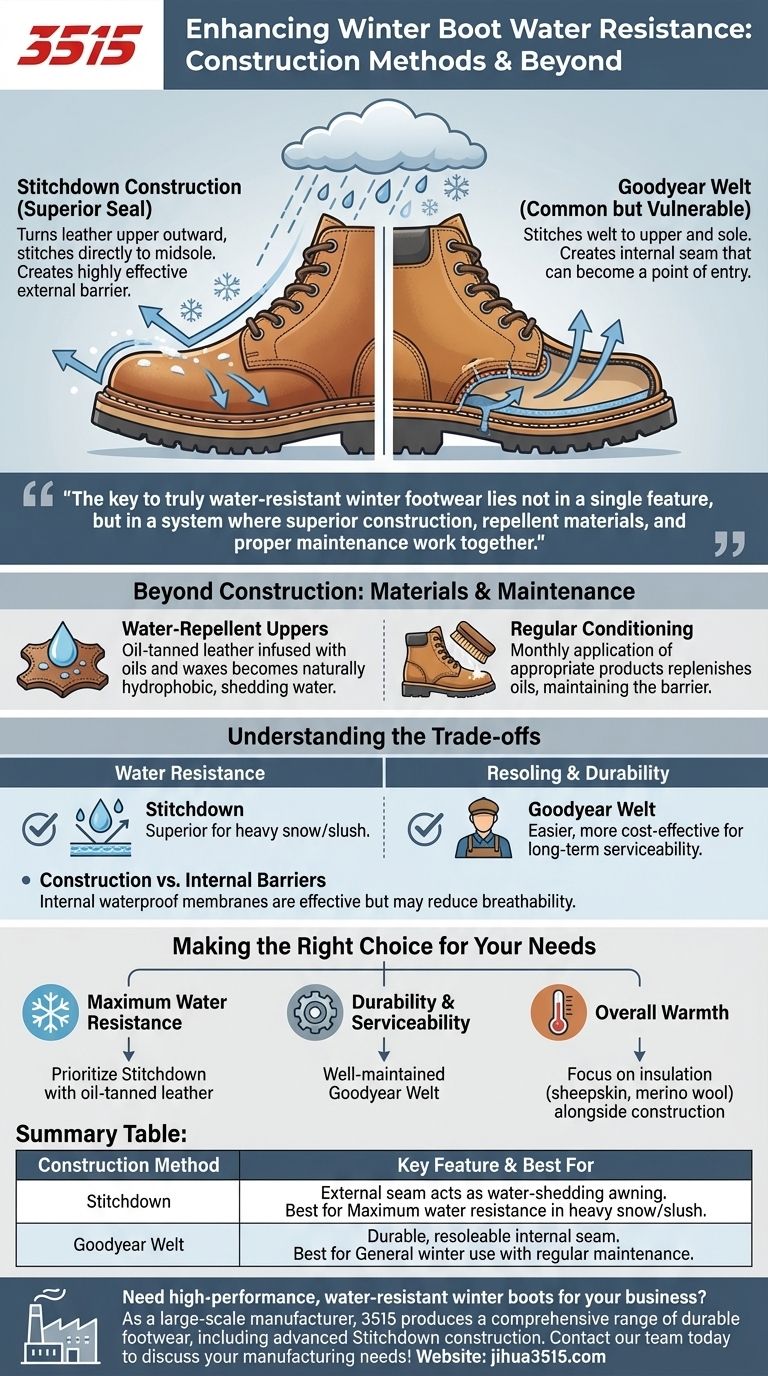

For winter boots, the single most effective construction method for enhancing water resistance is Stitchdown construction. Unlike more common methods like the Goodyear welt, a stitchdown design turns the leather upper outward and stitches it directly to the midsole. This creates a highly effective external barrier that sheds water away from the boot's seams, significantly reducing the potential for moisture to penetrate into the interior.

The key to truly water-resistant winter footwear lies not in a single feature, but in a system where superior construction, repellent materials, and proper maintenance work together to keep your feet dry and warm.

The Foundation of Water Resistance: Boot Construction

How a boot is assembled is the most critical factor in its ability to resist water over its lifetime. The seams are the weakest point, and the construction method determines how well those seams are protected.

Stitchdown Construction: The Superior Seal

In a Stitchdown boot, the leather upper is flared outward at the bottom edge. This flared edge is then stitched directly to the midsole and outsole.

This design creates a natural awning over the seam, forcing water and snow to run off the side rather than seep into the gap between the upper and the sole. It is inherently more water-resistant than methods that create an inward-facing seam.

Goodyear Welt: A Common but Vulnerable Method

The Goodyear welt is a very common, durable, and resoleable construction method. However, it involves stitching a strip of leather (the welt) to both the upper and the sole.

This process creates a small cavity and a seam that, over time and with wear, can become a point of entry for moisture. While excellent for many applications, it is structurally less resistant to water than a true stitchdown build.

Beyond Construction: The Role of Materials and Maintenance

Even the best construction is ineffective if the materials themselves absorb water. The upper material is your first line of defense.

Water-Repellent Uppers

Materials like oil-tanned leather are infused with oils and waxes during the tanning process. This treatment makes the leather naturally hydrophobic, causing water to bead up and roll off instead of soaking in.

The Importance of Regular Conditioning

Water-resistant properties are not permanent. To maintain the barrier, leather boots require regular care.

Monthly conditioning with an appropriate product replenishes the oils and waxes in the leather, ensuring it continues to repel water effectively through rain, slush, and snow.

Understanding the Trade-offs

Choosing the right boot means understanding that no single design is perfect for every situation. There are always compromises to be made.

Water Resistance vs. Resoling

While Stitchdown construction offers superior water resistance, the Goodyear welt is often considered easier and more cost-effective to resole multiple times. This is a key reason for its continued popularity in high-quality, long-lasting footwear.

Construction vs. Internal Barriers

Some boots compensate for less water-resistant construction by adding an internal waterproof membrane or liner. While effective, this can sometimes reduce breathability, potentially trapping sweat and leading to a different kind of dampness from within.

Making the Right Choice for Your Needs

Selecting the right boot depends entirely on the conditions you expect to face.

- If your primary focus is maximum water resistance for heavy snow and slush: Prioritize boots with a genuine Stitchdown construction and an oil-tanned leather upper.

- If your primary focus is durability and long-term serviceability for general winter use: A well-maintained Goodyear welt boot can be an excellent choice, provided you are diligent with conditioning.

- If your primary focus is overall warmth in cold, dry conditions: Pay equal attention to insulation, such as sheepskin lining or merino wool footbeds, alongside the boot's construction.

Ultimately, understanding how a boot is built empowers you to choose a tool perfectly suited for the job of keeping you warm and dry.

Summary Table:

| Construction Method | Key Water Resistance Feature | Best For |

|---|---|---|

| Stitchdown | External seam acts as a water-shedding awning | Maximum water resistance in heavy snow/slush |

| Goodyear Welt | Durable, resoleable internal seam | General winter use with regular maintenance |

Need high-performance, water-resistant winter boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, including advanced Stitchdown construction, ensuring your customers get the best protection against the elements.

Contact our team today to discuss your manufacturing needs and elevate your winter footwear line!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the essential characteristics of walking shoes for concrete surfaces? Protect Your Joints with the Right Footwear

- What is the price range for high-quality walking shoes? Find Your Perfect Fit for Comfort & Support

- What is the most important factor when choosing walking shoes? Find Your Perfect Fit for All-Day Comfort

- What types of boots are designed to protect tendons? Essential Leg Protection for Your Horse

- How do horse boots protect against self-inflicted injuries? A Guide to Equine Leg Safety

- What are the protective features of polo boots? Essential Defense for Equestrian Athletes

- How does proper boot fit enhance winter comfort? Achieve All-Day Warmth and Support

- Who wears cowboy boots today and where are they popular? From Workwear to Global Fashion Icon