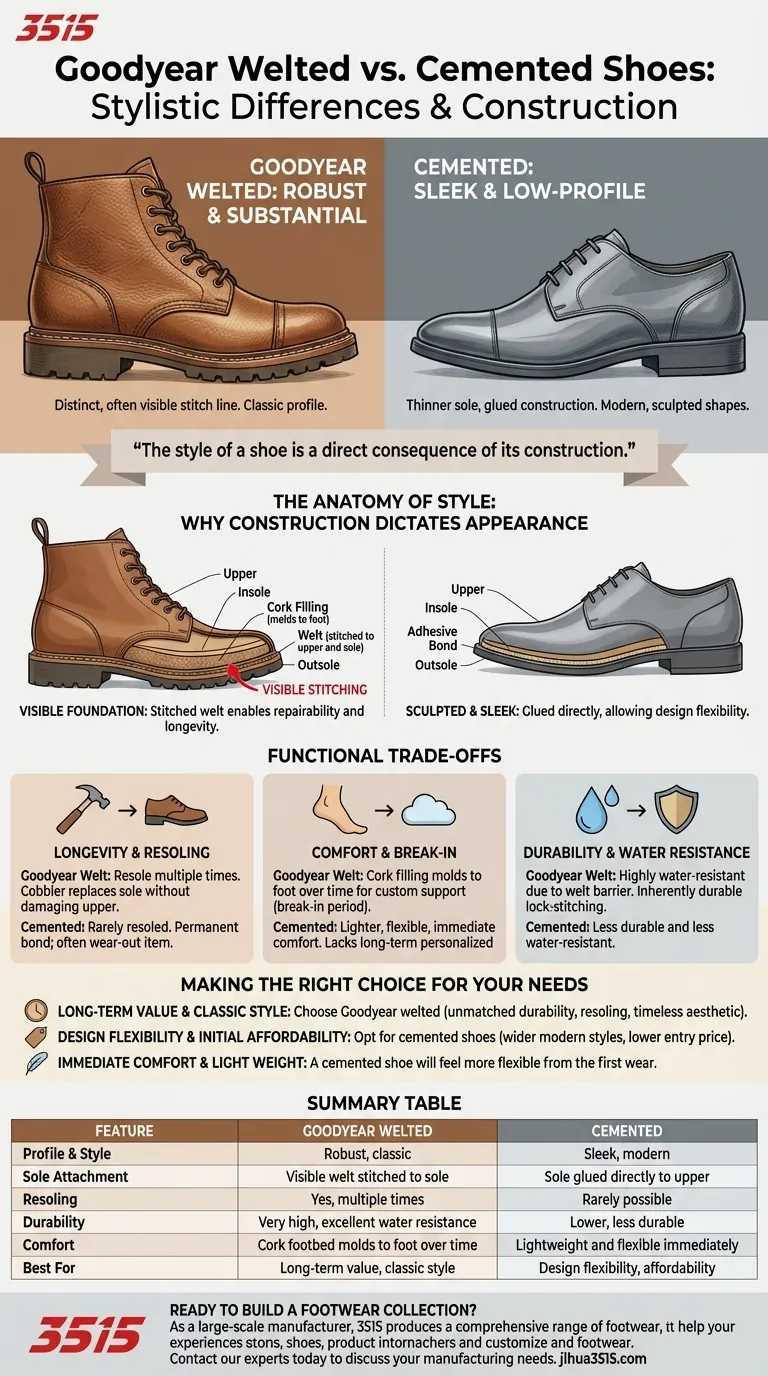

Visually, the key stylistic difference is that Goodyear welted shoes have a more robust and substantial profile with a distinct, often visible, stitch line running around the edge of the sole. In contrast, cemented shoes typically feature a sleeker, lower profile with thinner soles and a wider variety of modern, sculpted shapes.

The style of a shoe is not merely a design choice; it is a direct consequence of its construction. The visible bulk of a Goodyear welt enables repairability and longevity, while the sleekness of a cemented shoe prioritizes design flexibility and initial affordability.

The Anatomy of Style: Why Construction Dictates Appearance

The way a shoe's sole is attached to its upper fundamentally defines its shape, silhouette, and overall aesthetic. Understanding the two methods reveals why they look so different.

The Goodyear Welt: A Visible Foundation

A Goodyear welt is a strip of leather stitched around the bottom edge of the shoe's upper. This welt is then stitched to the sole, creating an incredibly strong and water-resistant bond.

This process results in a visible, often wider, edge where the upper meets the sole. It gives the shoe a solid, well-grounded appearance that is foundational to classic dress shoe and boot designs.

The Cemented Method: Sculpted and Sleek

Cemented construction involves applying a strong, industrial-grade adhesive to bond the sole directly to the shoe's upper. There is no intermediate welt or external stitching.

This lack of stitching and extra material gives designers immense stylistic flexibility. It allows for thinner, more contoured soles and more aggressive or unique toe shapes, such as sharp chisels or elongated almonds, that are difficult to achieve with a welt.

Functional Trade-offs That Shape the Style

The visual differences are intrinsically linked to the performance and lifespan of the shoe. Each construction method offers a distinct set of advantages and compromises.

Longevity and Resoling

The primary advantage of the Goodyear welt is its ability to be resoled multiple times. A cobbler can simply cut the stitches holding the old sole and attach a new one without compromising the shoe's upper.

Cemented shoes, however, are rarely designed to be resoled. The bond is permanent, and attempting to remove the sole often damages the upper, making them a "wear-out" item.

Comfort and Break-In

Goodyear welted shoes feature a cavity between the insole and outsole filled with cork. Over time, this cork molds to the unique shape of your foot, creating a custom, supportive fit. This often requires an initial break-in period.

Cemented shoes are typically lighter and more flexible right out of the box. They offer immediate comfort but lack the long-term, personalized support of a cork footbed.

Durability and Water Resistance

The welt acts as a physical barrier between the upper and the sole, making Goodyear welted shoes significantly more water-resistant than their cemented counterparts.

The construction is also inherently more durable due to the secure lock-stitching, which is why it's the standard for high-quality, long-lasting footwear.

Making the Right Choice for Your Needs

Your ideal shoe depends entirely on what you value most. The construction method is the most important factor in aligning a shoe with your goals.

- If your primary focus is long-term value and classic style: Choose Goodyear welted construction for its unmatched durability, resoling capability, and timeless aesthetic.

- If your primary focus is design flexibility and initial affordability: Opt for cemented shoes, which offer a wider range of modern styles and a lower entry price point.

- If your primary focus is immediate comfort and light weight: A cemented shoe will generally feel more flexible and less substantial from the very first wear.

Ultimately, understanding the construction behind the style empowers you to invest in footwear that truly serves your purpose.

Summary Table:

| Feature | Goodyear Welted | Cemented |

|---|---|---|

| Profile & Style | Robust, substantial, classic | Sleek, low-profile, modern |

| Sole Attachment | Visible welt stitched to sole | Sole glued directly to upper |

| Resoling | Yes, multiple times | Rarely possible |

| Durability | Very high, excellent water resistance | Lower, less durable |

| Comfort | Cork footbed molds to foot over time | Lightweight and flexible immediately |

| Best For | Long-term value, classic style | Design flexibility, initial affordability |

Ready to build a footwear collection that combines style, durability, and value?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether you need the timeless durability of Goodyear welted construction or the modern appeal of cemented styles, our production capabilities encompass all types of shoes and boots to meet your market's demands.

Contact our experts today to discuss your manufacturing needs and discover how we can bring quality and style to your product line.

Visual Guide

Related Products

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- Why are Oxford shoes considered the most versatile business footwear? Master Professional Style

- How do Monk Strap shoes differ from loafers? A Guide to Formality & Style

- What is the construction method used in Goodyear welted shoes? A Guide to Durable, Repairable Footwear

- What are Monk Strap shoes? The Ultimate Guide to Their Unique Style & Versatility

- What is the historical significance of men's formal shoes? A Journey from Status to Style

- How does Goodyear welt compare to Blake stitch? Choose the Right Shoe Construction for Your Needs

- What moderating role does social media sales intensity play in bulk dress shoe orders? Accelerate B2B Conversion Rates

- What is the role of personal preference in choosing between Goodyear welted and cemented shoes? Find Your Perfect Fit