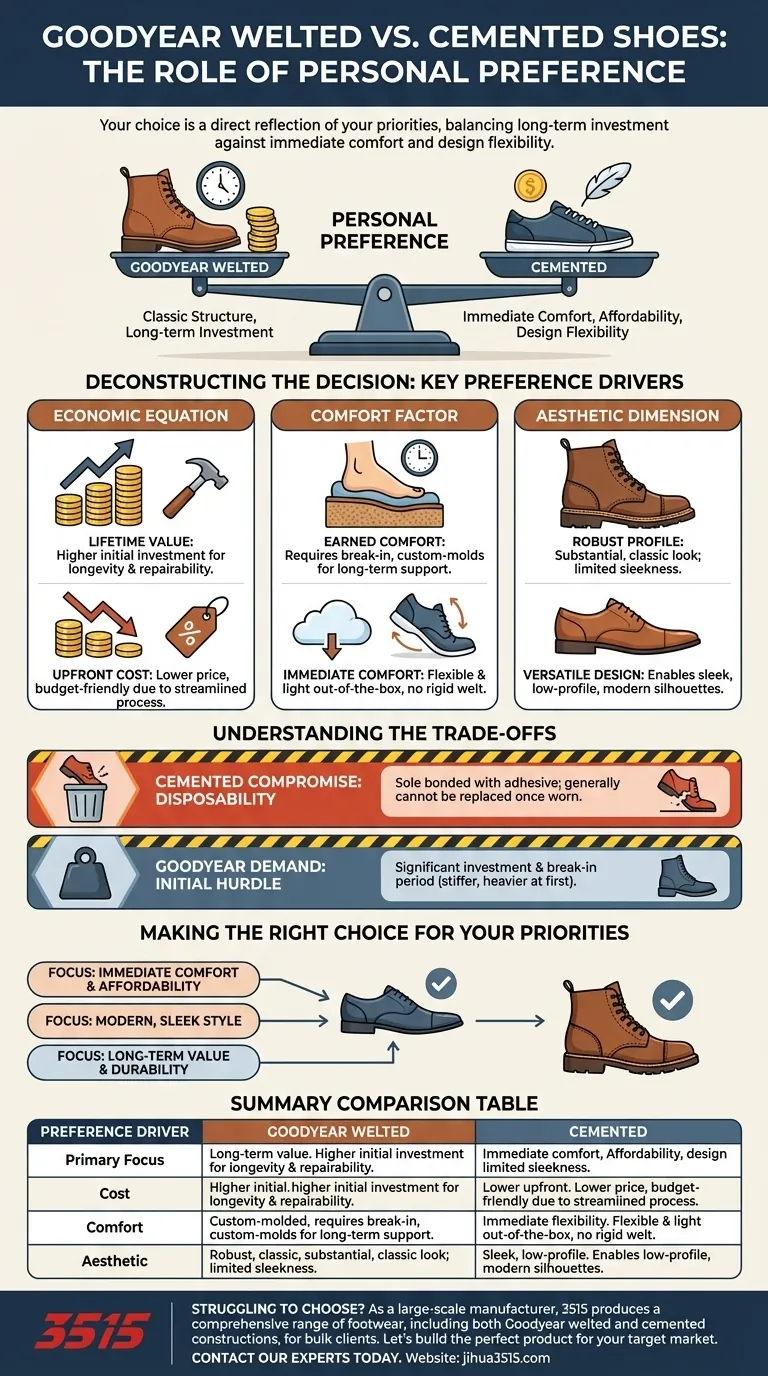

When choosing footwear construction, personal preference is not just a factor; it is the central pillar of your decision. The choice between a Goodyear welted and a cemented shoe is a direct reflection of your priorities, balancing the long-term investment and classic structure of a welt against the immediate comfort, affordability, and design flexibility of a cemented sole.

Your preference isn't about finding the objectively "best" shoe, but about aligning the shoe's construction method with your specific needs for budget, style, and comfort.

Deconstructing the Decision: Key Preference Drivers

The "better" choice is entirely subjective. Your personal preference is ultimately shaped by how you weigh three distinct factors against one another.

The Economic Equation: Upfront Cost vs. Lifetime Value

Goodyear welted shoes represent a significant initial investment. This higher cost is due to the skilled labor and materials required for a construction method designed for longevity and repair.

Cemented shoes are far more accessible from a budget standpoint. Their streamlined, adhesive-based manufacturing process results in a lower upfront price, making them a practical choice for many.

The Comfort Factor: Immediate vs. Earned

Cemented shoes are often praised for their out-of-the-box comfort. The lack of a rigid welt and insole makes them lighter and more flexible from the very first wear.

Goodyear welted shoes demand a break-in period. However, as the cork footbed compresses and the leather molds to your foot, they provide a level of customized support that cemented shoes cannot replicate over the long term.

The Aesthetic Dimension: Profile and Versatility

The Goodyear welting process naturally creates a more substantial and robust shoe profile. While a hallmark of classic, durable footwear, this can limit the ability to create very sleek or modern silhouettes.

Cemented construction offers greater design freedom. Designers can create shoes with thinner, lower-profile soles and more varied shapes, such as sharp chisel or elegant almond toes, catering to a wider range of contemporary styles.

Understanding the Trade-offs

Neither method is without its compromises. Acknowledging them is key to making an informed decision that you won't regret.

The Compromise of Cemented Shoes

The primary trade-off is disposability. Because the sole is bonded with adhesive, it generally cannot be replaced. Once the sole is worn through, the shoe's life is effectively over.

This construction can also offer less structural support and breathability compared to a welted shoe, which may be a factor for those who spend long hours on their feet.

The Demands of a Goodyear Welt

The most significant hurdle is the initial investment and the required break-in period. These shoes are typically stiffer and heavier at first, which can be a deal-breaker for those seeking immediate comfort.

Furthermore, their inherently thicker sole profile may not align with a preference for minimalist or highly modern aesthetics.

Making the Right Choice for Your Priorities

Ultimately, your preference should guide you to the construction that best serves your intended use and personal values.

- If your primary focus is immediate comfort and affordability: A cemented shoe is the logical choice, delivering flexibility and a lower price point from day one.

- If your primary focus is modern, sleek style: Cemented construction provides the design freedom for thinner profiles and varied shapes that welted shoes often cannot match.

- If your primary focus is long-term value and durability: A Goodyear welted shoe is a clear investment that pays dividends through its repairability and custom-molded fit over years of wear.

By understanding how each construction method serves these different priorities, you can confidently select the shoe that is truly built for you.

Summary Table:

| Preference Driver | Goodyear Welted | Cemented |

|---|---|---|

| Primary Focus | Long-term value, durability, repairability | Immediate comfort, affordability, modern style |

| Cost | Higher initial investment | Lower upfront price |

| Comfort | Custom-molded fit after break-in | Immediate flexibility and lightness |

| Aesthetic | Robust, classic profile | Sleek, low-profile, versatile designs |

Struggling to choose the right construction for your footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including both Goodyear welted and cemented constructions. We can help you navigate these choices to deliver the perfect product for your target market.

Let's build the perfect shoe for your customers. Contact our experts today to discuss your production needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- How can chukka boots be broken in for comfort? A Gentle Guide to a Custom Fit

- How does the Goodyear-welt construction enhance shoe durability? Engineered for Decades of Wear

- How does Goodyear Welted construction contribute to sustainability? Unlock Decades of Wear with Repairable Design

- What makes double monk strap shoes suitable for formal occasions? A Guide to Elegant Style

- How can one find high-quality Goodyear welted shoes at lower prices? A Guide to Smart, Value-Driven Footwear

- What factors influence the decision between Goodyear welted and cemented shoes? Make the Right Choice for Your Needs

- For what occasions are penny loafers suitable? A Guide to Versatile Style

- What is Goodyear welt construction? A Guide to Durable, Repairable Footwear