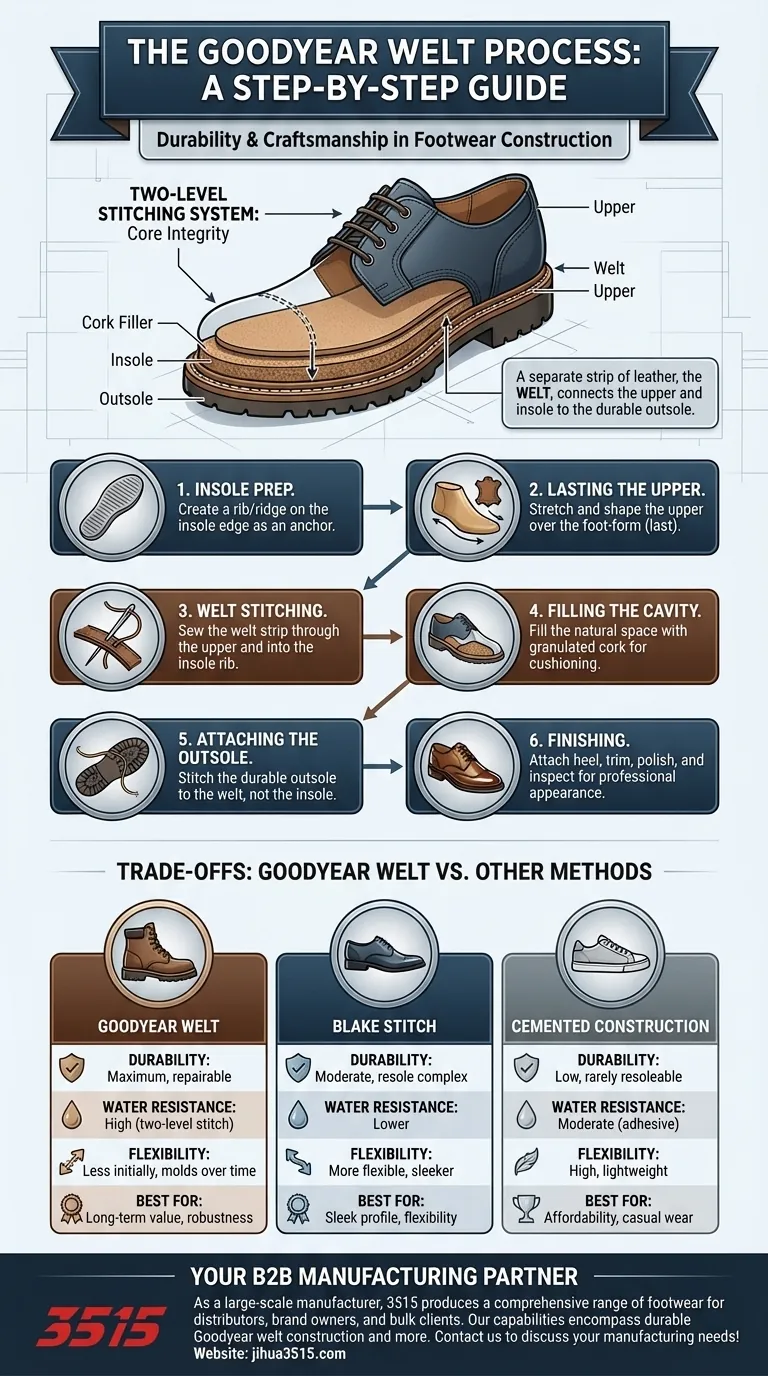

At its core, the Goodyear welt process is a meticulous method of shoe construction that involves stitching a separate strip of leather, known as the welt, to both the upper and the insole of the shoe. A durable outsole is then stitched directly to this welt, creating a robust, water-resistant, and easily repairable structure.

The central principle of a Goodyear welt is its two-level stitching system. The first stitch connects the upper, insole, and welt, while a separate, exterior stitch attaches the outsole to the welt, ensuring the shoe's core integrity is never compromised during resoling.

A Step-by-Step Breakdown of the Goodyear Welt

To truly appreciate the durability and craftsmanship of this method, it's essential to understand each stage of the process. Every step builds upon the last to create a cohesive and long-lasting final product.

Preparation of the Insole

The foundation of the shoe is the insole. A small vertical ridge, often called a "rib," is created around the insole's edge. This rib serves as the crucial anchor point for the subsequent stitching that will hold the shoe together.

Lasting the Upper

The leather upper, which forms the main body of the shoe, is stretched and shaped over a foot-form called a last. It is then temporarily secured to the insole, giving the shoe its fundamental shape.

Stitching the Welt

This is the signature step. The welt—a narrow strip of leather—is sewn through the leather upper and into the prepared rib on the insole. This first, critical stitch chain firmly binds the upper part of the shoe to its foundation.

Filling the Cavity

The process of attaching the welt creates a natural cavity between the insole and what will become the outsole. This space is filled with a layer of granulated cork. The cork provides cushioning, insulation, and over time, molds to the shape of the wearer's foot for a custom fit.

Attaching the Outsole

The durable outsole is placed onto the bottom of the shoe. A second, separate, and very strong stitch is then sewn through the outsole and into the welt. Crucially, this stitch does not penetrate the insole, which is a key factor in the shoe's water resistance. A high-strength adhesive is often used alongside the stitching for maximum bond.

Finishing the Shoe

Finally, the heel is attached, the edges of the sole are trimmed and polished, and the shoe undergoes final cleaning and inspection. This finishing stage ensures a clean, professional appearance.

Understanding the Trade-offs: Goodyear vs. Other Methods

The Goodyear welt is renowned for its quality, but it is not the only method of shoe construction. Understanding its advantages and disadvantages compared to other common techniques is key to making an informed choice.

The Goodyear Welt Advantage

The primary benefits are durability and repairability. Because the outsole is stitched to the welt and not the upper, a cobbler can easily remove the old sole and stitch on a new one multiple times without disturbing the shoe's core structure. The two-level stitching also creates a more effective barrier against water.

Comparison to Blake Stitch

In a Blake stitch construction, a single stitch runs directly from the outsole through the insole and upper. This creates a sleeker, more flexible shoe with a closer-cut sole. However, it is less water-resistant, and resoling is more complex as it requires a specific Blake stitching machine.

Comparison to Cemented Construction

Cemented construction is the simplest method, where the outsole is attached to the upper using only strong adhesive. This is fast and inexpensive, resulting in lightweight and flexible shoes. The drawback is a significant lack of durability, and these shoes can almost never be resoled.

Making the Right Choice for Your Footwear

Your ideal shoe construction method depends entirely on your priorities for performance, longevity, and style.

- If your primary focus is maximum durability and long-term value: The Goodyear welt is the definitive choice, offering unparalleled repairability and robustness.

- If your primary focus is a sleek profile and immediate flexibility: A Blake-stitched shoe offers a more refined silhouette right out of the box.

- If your primary focus is affordability and a lightweight feel: Cemented construction provides an accessible entry point for casual or occasional wear.

Understanding how a shoe is made empowers you to invest in footwear that truly aligns with your needs.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Insole Prep | Create a rib/ridge on the insole edge. | Anchor point for stitching. |

| 2. Lasting | Stretch and shape the upper over the last. | Gives the shoe its fundamental shape. |

| 3. Welt Stitching | Sew the welt strip to the upper and insole rib. | Binds the upper to the shoe's foundation. |

| 4. Cork Filling | Fill the cavity with granulated cork. | Provides cushioning and molds to the foot. |

| 5. Outsole Attaching | Stitch and glue the outsole to the welt. | Creates a durable, water-resistant base. |

| 6. Finishing | Attach heel, trim, and polish. | Ensures a clean, professional appearance. |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the durable Goodyear welt construction. Let us help you build a superior product line that your customers will value for years to come.

Contact us today to discuss your manufacturing needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health