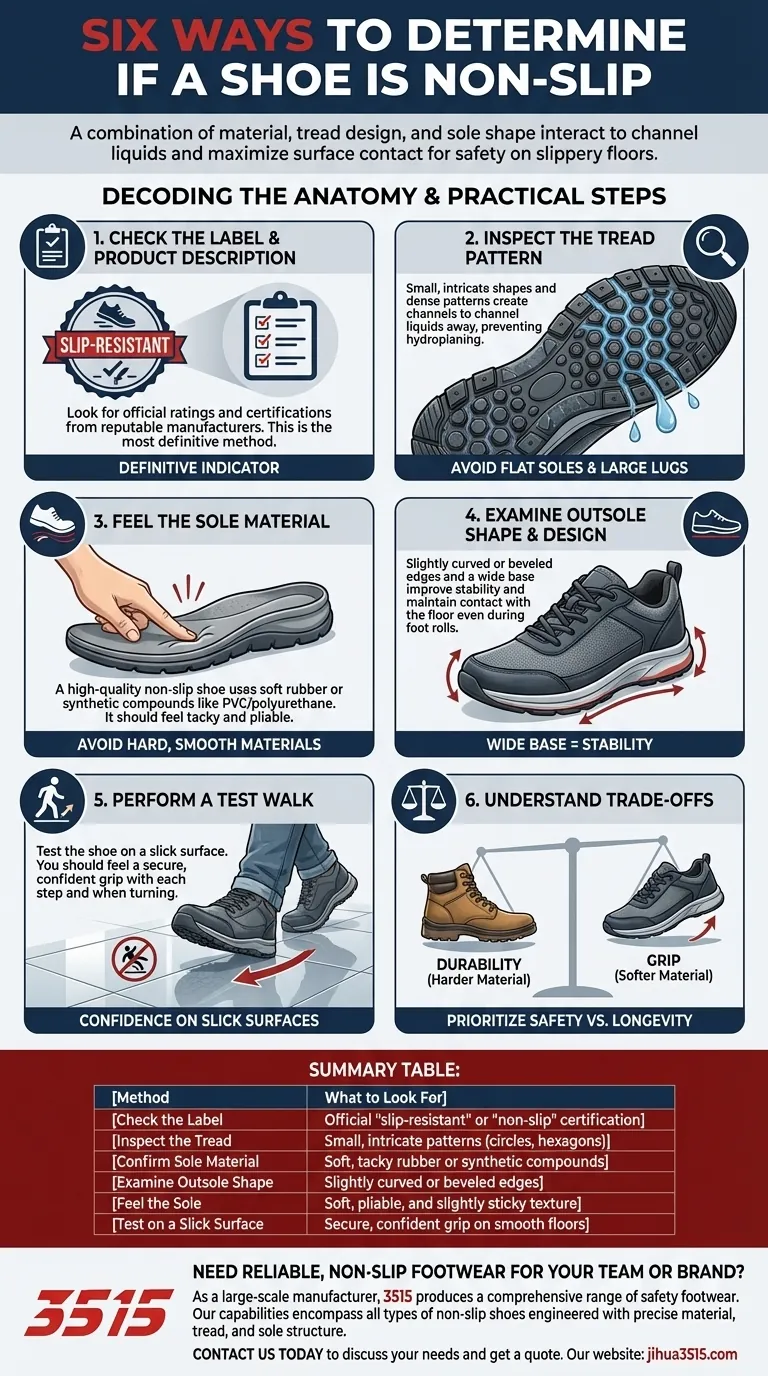

The six primary ways to determine if a shoe is non-slip are to check the product label for official ratings, inspect the tread for specific patterns, confirm the sole is made of soft rubber, examine the outsole's shape for curved edges, feel the sole for a tacky grip, and test the shoe on a slick surface. These factors work together to provide traction on wet, oily, or otherwise hazardous floors.

The core principle of a non-slip shoe isn't just one feature, but a combination of material, tread design, and sole shape. True slip resistance comes from how these elements interact to channel away liquids and maximize surface contact.

Decoding the Anatomy of a Non-Slip Shoe

A shoe's ability to prevent a slip is determined almost entirely by its outsole—the part that contacts the ground. Understanding what to look for in the material and design of this single component is the key to assessing its effectiveness.

The Foundation: Outsole Material

The material of the outsole is your first and most critical indicator. It dictates the shoe's fundamental ability to grip a surface.

Look for soft rubber. A high-quality non-slip shoe will almost always have a sole made from soft rubber or a similar synthetic compound like PVC or polyurethane. This material is naturally tacky and conforms slightly to microscopic imperfections in the floor, increasing friction.

Avoid hard, smooth materials. Leather, hard plastic, or foam-like materials (common in casual or dress shoes) offer very little traction, especially on wet surfaces. They are designed for durability or aesthetics, not safety.

The Engineering: Tread Pattern

The pattern carved into the outsole is not for looks; it's a functional system designed to manage liquids.

Small, intricate shapes are best. Look for patterns made of small circles, hexagons, or dense squiggles. These small shapes create numerous edges that can bite into the floor for better grip.

They create channels for liquid. The primary job of the tread is to channel water, oil, and other contaminants away from the point of contact between the sole and the floor. Without these channels, a thin layer of liquid can cause hydroplaning, leading to a slip. Wider, shallower grooves are less effective.

The Structure: Outsole Shape and Design

The overall shape of the sole contributes significantly to stability and surface contact.

Look for slightly curved edges. A sole with rounded or beveled edges helps maintain contact with the floor even when your foot rolls slightly. A hard, 90-degree edge can lose contact more easily.

A wider base provides stability. A broader sole creates a more stable platform, reducing the likelihood of your ankle rolling and causing a loss of balance that can lead to a slip.

Practical Steps for Verification

While understanding the anatomy is crucial, you need practical methods to confirm your assessment before making a purchase or relying on a pair of shoes.

Method 1: Check the Label and Product Description

This is the most definitive method. Reputable manufacturers will clearly label their shoes as "slip-resistant" or "non-slip." Look for official ratings if they are provided, as these indicate the shoe has passed standardized tests.

Method 2: Inspect the Tread Pattern

Flip the shoe over. Are the patterns small, dense, and intricate? Can you see clear channels that would allow water to escape from under the shoe? If the sole is mostly flat or has large, shallow lugs, it is not a true non-slip design.

Method 3: Feel the Sole

Use your hand to feel the outsole material. It should feel soft, pliable, and slightly sticky or tacky to the touch. A hard, smooth plastic feel is a clear warning sign.

Method 4: The Test Walk

If possible, wear the shoes in the store. Walk on the smoothest, most polished floor you can find (tile is a great test surface). Pay attention to how the sole grips the floor as you walk and turn. You should feel a secure, confident connection with each step.

Understanding the Trade-offs

It's important to recognize that no shoe is "slip-proof," and features that enhance grip can come with compromises.

Durability vs. Grip

The soft rubber compounds that provide the best grip are often less durable than harder materials. A high-performance non-slip shoe may wear down its tread faster than a standard work boot, especially if used frequently on abrasive surfaces like concrete.

Specialized vs. General Use

A shoe designed for a greasy kitchen floor (requiring oil resistance and channeling) might not be the best choice for icy conditions, which call for a different type of tread or even metal studs. Always match the shoe's intended purpose to your specific environment.

Comfort and Style

Historically, non-slip shoes prioritized function over form. While modern designs have improved significantly, the features required for safety—like a wider base and thick rubber sole—can make them heavier or less sleek than fashion footwear.

Making the Right Choice for Your Goal

Your specific need will determine which features to prioritize when selecting a shoe.

- If your primary focus is safety in a professional setting (e.g., kitchen, hospital): Prioritize shoes with an official "slip-resistant" certification and a dense, liquid-channeling tread pattern.

- If your primary focus is everyday traction on varied surfaces (e.g., wet sidewalks): Focus on a soft rubber sole with a multi-directional tread pattern for reliable grip.

- If you are trying to improve existing shoes: While not ideal, applying traction pads or having a cobbler resole them with proper materials are the most effective options.

Ultimately, choosing the right footwear is a critical step in preventing injury in any potentially slippery environment.

Summary Table:

| Method | What to Look For |

|---|---|

| Check the Label | Official "slip-resistant" or "non-slip" certification. |

| Inspect the Tread | Small, intricate patterns (circles, hexagons) for channeling liquids. |

| Confirm Sole Material | Soft, tacky rubber or synthetic compounds like PVC/polyurethane. |

| Examine Outsole Shape | Slightly curved or beveled edges for better floor contact. |

| Feel the Sole | A soft, pliable, and slightly sticky texture. |

| Test on a Slick Surface | A secure, confident grip when walking on smooth tile or polished floors. |

Need reliable, non-slip footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip shoes and boots, engineered with the precise material, tread design, and sole structure detailed in this article to maximize traction and prevent workplace injuries.

Contact us today to discuss your non-slip footwear needs and get a quote.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now