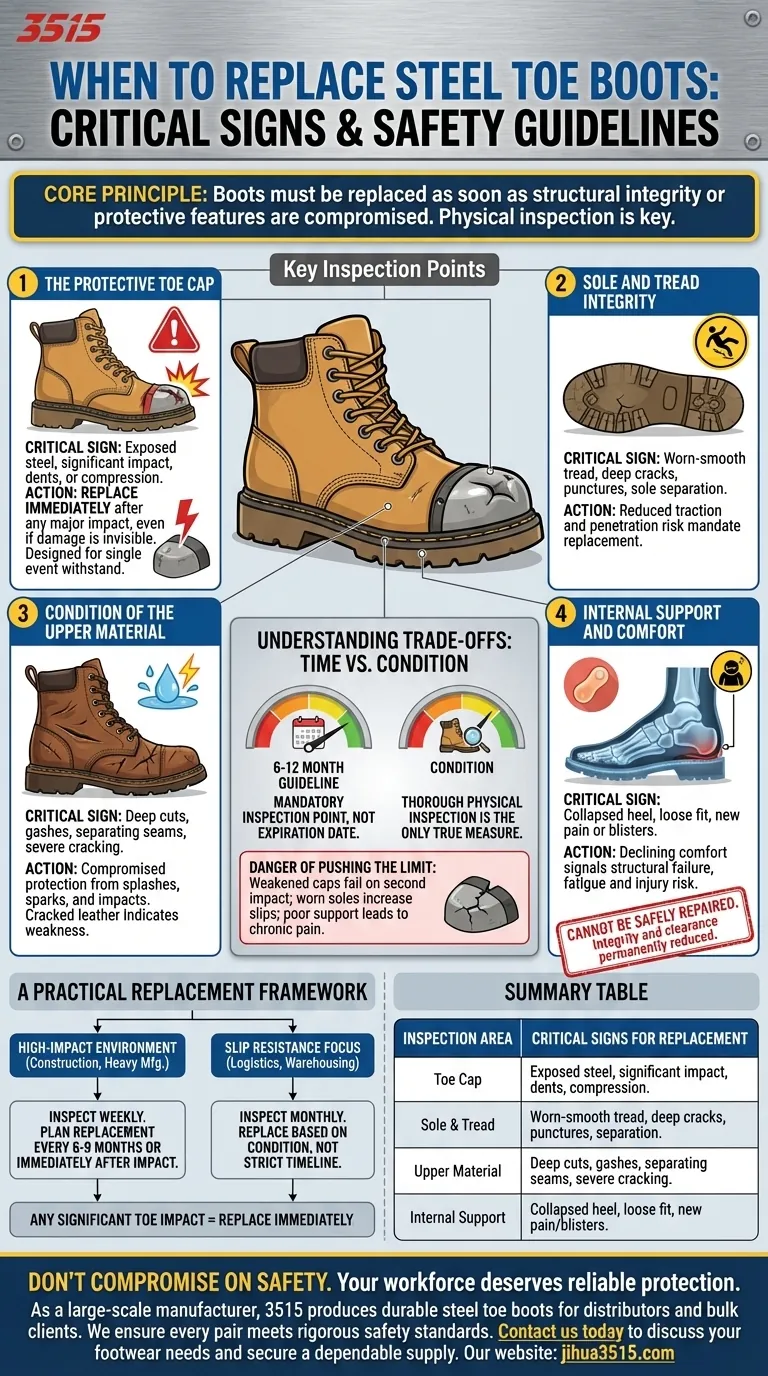

Knowing when to replace your steel toe boots is a critical safety decision that goes beyond simple wear and tear. The most immediate signs are visible damage like an exposed steel cap, deep cuts in the upper material, or soles that are separating or worn smooth. Any significant impact to the toe area also mandates immediate replacement, even if the damage isn't obvious.

The core principle is this: your boots must be replaced as soon as their structural integrity or protective features are compromised. Time-based guidelines are useful reminders, but a thorough physical inspection is the only true measure of safety.

The Anatomy of Failure: Key Inspection Points

To properly assess your boots, you need to look at them as a complete safety system. Each part has a critical function, and failure in one area can compromise the entire boot.

The Protective Toe Cap

The steel toe is the most critical safety feature. After any significant impact from a falling or rolling object, the boot must be replaced immediately. The cap is designed to withstand a single major event; even if it appears undamaged, its structural integrity may be compromised.

Sole and Tread Integrity

The sole provides both support and slip resistance. Check for a tread depth that has become shallow, which severely reduces traction on wet or uneven surfaces. Also, look for deep cracks or punctures that could allow sharp objects or hazardous liquids to penetrate.

Condition of the Upper Material

The "upper" is the material covering the top of your foot. Deep cuts, gashes, or separating seams compromise the boot's ability to protect you from splashes, sparks, or impacts. For leather boots, significant cracking indicates the material has dried out and lost its strength.

Internal Support and Comfort

A decline in comfort is often a direct signal of structural failure. If the boot feels loose, the heel support has collapsed, or you experience new rubbing or irritation, it means the internal structure is no longer providing adequate support. This increases fatigue and the risk of sprains or blisters.

Understanding the Trade-offs: Time vs. Condition

While a physical inspection is paramount, it's helpful to understand the context of time-based replacement guidelines.

The "6-12 Month" Guideline

Many safety guidelines suggest replacing boots every six to twelve months. This should be treated as a mandatory inspection point, not an absolute expiration date. The actual lifespan of your boots depends entirely on your work environment and frequency of use.

The Danger of Pushing the Limit

Continuing to wear compromised boots introduces unacceptable risks. A weakened toe cap might fail during a second impact, worn soles increase the likelihood of slips and falls, and a lack of structural support can lead to chronic foot, knee, and back pain.

Why You Can't "Repair" a Damaged Toe

Once a steel toe cap is dented, compressed, or exposed, it cannot be safely repaired. The integrity of the cap and the clearance space for your toes have been permanently reduced, and the boot is no longer compliant with safety standards.

A Practical Replacement Framework

Use your specific job function and environment to determine the right course of action for maintaining your safety.

- If your primary focus is working in a high-impact environment (construction, heavy manufacturing): Inspect your boots weekly for damage and plan for replacement every 6 to 9 months, or immediately after any toe impact incident.

- If your primary focus is on slip resistance and support (logistics, warehousing, light industrial): Conduct a thorough inspection monthly, paying close attention to sole and tread wear, with replacement based on condition rather than a strict timeline.

- If your boot has sustained any significant impact to the toe area: Replace it immediately, regardless of its age or outward appearance.

Ultimately, your safety boots are a non-negotiable piece of personal protective equipment; treat their condition with the seriousness it deserves.

Summary Table:

| Inspection Area | Critical Signs for Replacement |

|---|---|

| Toe Cap | Exposed steel, any significant impact, dents, or compression. |

| Sole & Tread | Worn-smooth tread, deep cracks, punctures, or sole separation. |

| Upper Material | Deep cuts, gashes, separating seams, or severe cracking (leather). |

| Internal Support | Collapsed heel, loose fit, or new pain/blisters indicating support failure. |

Don't compromise on safety. Your workforce deserves reliable, high-quality protective footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of durable steel toe boots and shoes for distributors, brand owners, and bulk clients. We ensure every pair meets rigorous safety standards.

Contact us today to discuss your footwear needs and secure a dependable supply of safety-certified boots.

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?