To be considered genuinely slip-resistant, a shoe must go beyond simple claims and meet specific technical criteria. Its effectiveness is rooted in the combination of a synthetic rubber outsole, a deep and intricate tread pattern designed to channel liquids away, and ideally, an official safety certification (like SRC) that proves its performance on hazardous surfaces.

The term "slip-resistant" is not just a marketing label; it's a functional characteristic defined by material science and engineering. True slip resistance comes from a synergy between the sole's material, the tread's design, and independent testing that validates its ability to maintain friction on wet and oily surfaces.

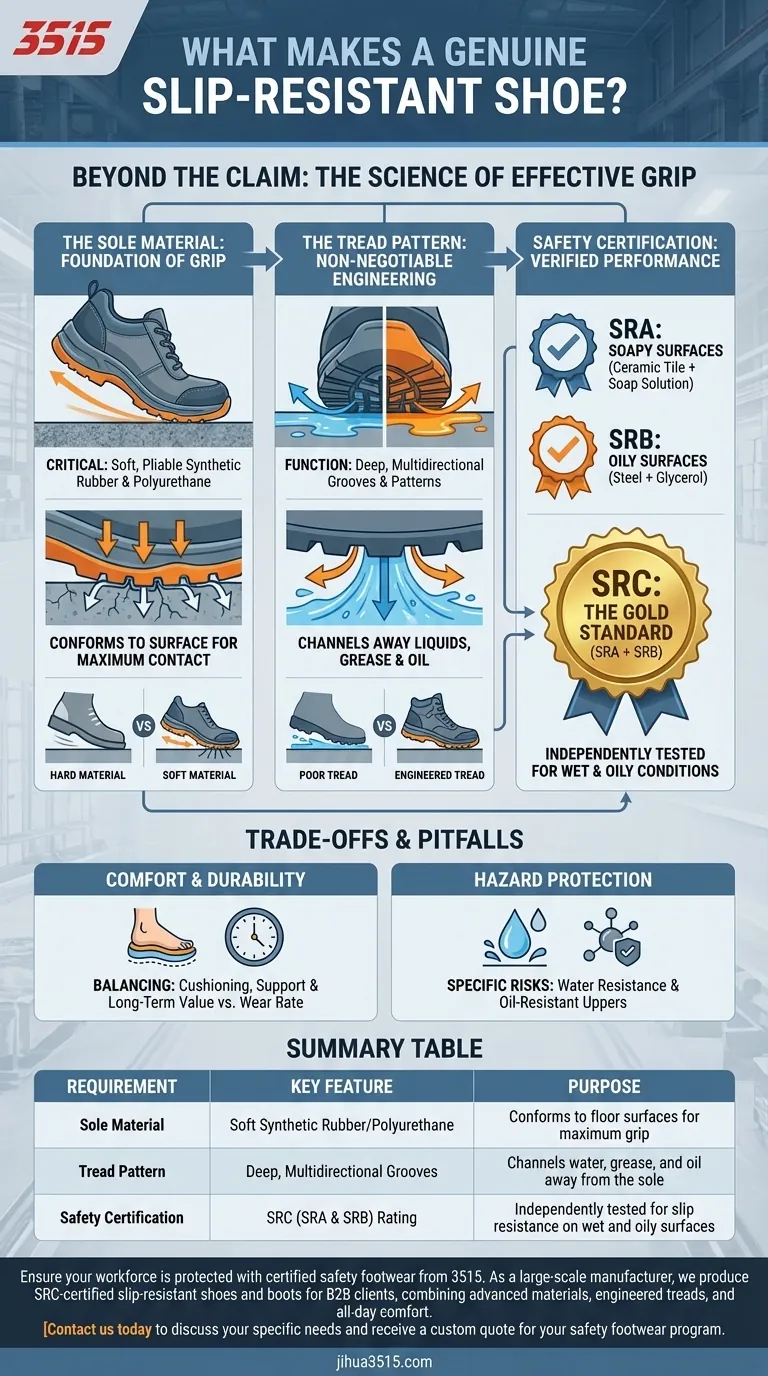

The Science of an Effective Grip

A shoe's ability to prevent a slip is determined by how its sole interacts with the ground at a microscopic level. It's a system where every component must work together to maximize friction.

The Critical Role of Sole Material

The foundation of any slip-resistant shoe is a soft, pliable outsole. Synthetic rubber and polyurethane (PU) are the industry standards for this purpose.

Unlike harder materials found on standard shoes, these compounds are designed to conform to the tiny imperfections on a floor surface, maximizing contact and creating a stronger grip.

Why Tread Pattern is Non-Negotiable

The tread is the most visible feature, but its function is often misunderstood. Its primary job is not just to "grip," but to channel away contaminants like water, grease, and oil.

Effective treads are deep and feature multidirectional grooves and patterns. This design creates pathways for liquid to escape from underneath the sole, allowing the rubber to make direct contact with the actual floor surface, which is essential for generating friction.

The Interplay of Material and Tread

Neither an advanced material nor a deep tread can function effectively alone. A soft rubber sole with a poor tread pattern will aquaplane on wet surfaces, while a great tread made from hard plastic will simply skate over them.

Genuine slip-resistant footwear combines a soft, high-friction material with a tread pattern engineered to clear liquids efficiently.

How to Verify a "Slip-Resistant" Claim

Professional safety footwear undergoes standardized testing to prove its claims. These certifications remove the guesswork and provide objective proof of performance.

SRA: The Test for Soapy Surfaces

A shoe with an SRA rating has been tested on a ceramic tile surface wetted with a soap solution. This simulates conditions commonly found in kitchens, hospitals, and cleaning environments.

SRB: The Test for Oily Surfaces

An SRB rating means the shoe was tested on a smooth steel surface coated with glycerol. This mimics the slick, oily conditions found in industrial settings, garages, and manufacturing plants.

SRC: The Gold Standard of Certification

The SRC rating is the most comprehensive and sought-after certification. A shoe must pass both the SRA and the SRB tests to earn this rating. For most professional applications, looking for an SRC rating is the safest and most reliable approach.

Understanding the Trade-offs and Pitfalls

A certified sole is the most important factor, but it's not the only one. Ignoring other aspects of the shoe can undermine its safety and utility.

Comfort vs. Compliance

An uncomfortable safety shoe is a shoe that won't be worn. Features like proper cushioning, arch support, and a roomy toe box are critical for ensuring the footwear is worn consistently throughout a long shift.

Durability and Long-Term Value

The soft rubber compounds that make soles slip-resistant can wear down faster than harder materials. A quality shoe is built for durability to ensure it provides reliable protection over time, offering better value and safety than a cheaper alternative that requires frequent replacement.

Hazard-Specific Protection

The sole provides grip, but the rest of the shoe must protect you from the specific hazards of your job. This includes water resistance to keep your feet dry or oil-resistant uppers that won't degrade when exposed to chemicals.

Making the Right Choice for Your Goal

Selecting the right shoe means matching its certified capabilities to the specific risks of your work environment.

- If your primary focus is a wet environment (e.g., kitchens, hospitals): Look for an SRC or SRA certified shoe with a soft rubber sole and intricate treads designed to disperse water.

- If your primary focus is an oily or industrial environment (e.g., garages, factories): Prioritize an SRC or SRB certified shoe, as its grip has been proven on slippery, glycerol-coated steel.

- If your primary focus is all-day wear and general safety: Choose an SRC-certified shoe that also offers excellent cushioning and ergonomic support to ensure you wear it consistently and comfortably.

Ultimately, a genuine slip-resistant shoe is a piece of certified safety equipment engineered for your specific workplace.

Summary Table:

| Requirement | Key Feature | Purpose |

|---|---|---|

| Sole Material | Soft Synthetic Rubber/Polyurethane | Conforms to floor surfaces for maximum grip |

| Tread Pattern | Deep, Multidirectional Grooves | Channels water, grease, and oil away from the sole |

| Safety Certification | SRC (SRA & SRB) Rating | Independently tested for slip resistance on wet and oily surfaces |

Ensure your workforce is protected with certified safety footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of SRC-certified slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our footwear combines advanced materials, engineered treads, and ergonomic design for all-day comfort and compliance.

Contact us today to discuss your specific needs and receive a custom quote for your safety footwear program.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do safety shoes protect workers in precast concrete production? Essential Steel Toe and Midsole Protection Guide

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What is the purpose of steel-toe moc toe boots? Achieve All-Day Safety and Comfort

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- How does the structural design of industrial-grade safety shoes provide protection? Engineering Foot Health at Work