At its core, a work shoe is a piece of specialized equipment designed primarily for protection and support in a specific occupational environment. Unlike an athletic or casual shoe built for comfort and performance in motion, a work shoe prioritizes features that mitigate workplace hazards, such as reinforced safety toes, highly durable materials, and robust structural support for long periods of standing or labor.

The fundamental difference is one of purpose. A standard shoe is designed for the comfort of the wearer, while a work shoe is engineered first and foremost for the safety and support required by the job itself.

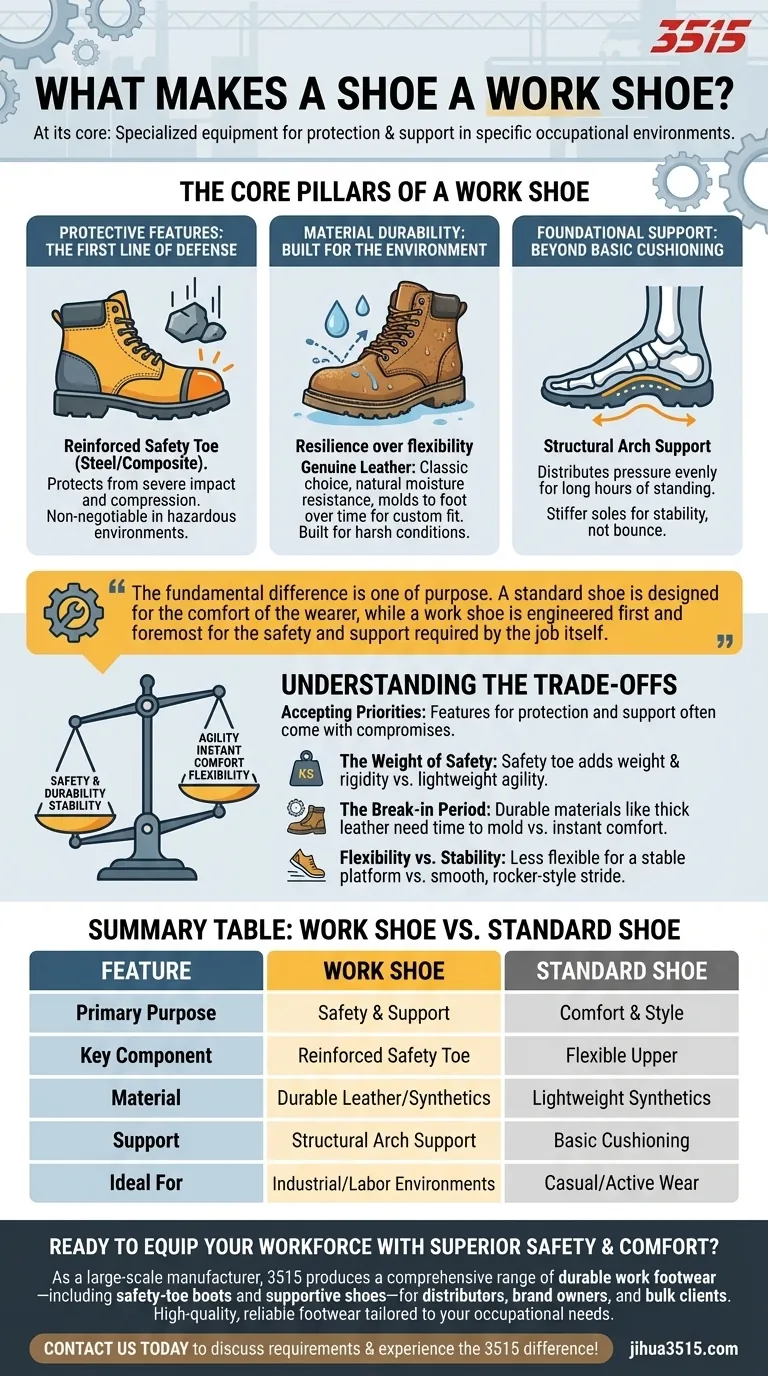

The Core Pillars of a Work Shoe

To truly understand what defines a work shoe, we must look at its key components, each engineered to solve a specific problem common in manual labor and industrial environments.

Protective Features: The First Line of Defense

The most defining characteristic of many work shoes is the reinforced safety toe. This is a non-negotiable feature in environments where heavy or sharp objects pose a risk.

This toe box, often made of steel or a lighter composite material, is designed to protect the foot from severe impact and compression, a common hazard that is simply not a consideration for a standard athletic or dress shoe.

Material Durability: Built for the Environment

Work shoes are constructed from materials chosen for resilience over flexibility or light weight. Genuine leather is a classic choice for its inherent durability and natural resistance to moisture.

Over time, materials like leather mold to the wearer's foot, providing a custom fit. This focus on long-term durability stands in contrast to the lightweight synthetics used in walking shoes, which prioritize breathability and immediate comfort.

Foundational Support: Beyond Basic Cushioning

While a walking shoe focuses on soft cushioning for shock absorption during movement, a work shoe emphasizes structural arch support. This is critical for distributing pressure evenly across the feet during long hours of standing.

Inadequate support can lead to arch pain and even lower back pain. Work shoes address this with contoured footbeds and stiffer soles designed for stability under load, not for the responsive "bounce" of a running shoe.

Understanding the Trade-offs

Choosing a work shoe means accepting a different set of priorities. The features that provide protection and support often come with compromises in other areas.

The Weight of Safety

A steel or composite safety toe adds significant weight and rigidity. This is a direct trade-off for protection against impact, making the shoe feel heavier and less agile than a lightweight running shoe.

The Break-in Period

Durable materials like thick leather require a "break-in" period to become comfortable as they mold to your foot. This contrasts sharply with most athletic shoes, which are designed for instant comfort out of the box.

Flexibility vs. Stability

Work shoes are often less flexible to provide a more stable platform. This rigidity protects your foot but can feel restrictive compared to the smooth, rocker-style midsole of a modern walking shoe designed to facilitate an easy stride.

Making the Right Choice for Your Goal

Selecting the correct shoe requires you to match its features to the specific demands and hazards of your job.

- If your primary focus is protection from falling objects: A certified safety toe is the single most important feature to look for.

- If your primary focus is all-day standing comfort: Prioritize a shoe with excellent, contoured arch support to prevent fatigue and pain.

- If your primary focus is durability in a harsh environment: Select a shoe made from a robust material like genuine leather that can withstand abrasion and exposure.

Ultimately, the right work shoe is a specialized tool engineered to keep you safe and supported throughout your workday.

Summary Table:

| Feature | Work Shoe | Standard Shoe |

|---|---|---|

| Primary Purpose | Safety & Support | Comfort & Style |

| Key Component | Reinforced Safety Toe | Flexible Upper |

| Material | Durable Leather/Synthetics | Lightweight Synthetics |

| Support | Structural Arch Support | Basic Cushioning |

| Ideal For | Industrial/Labor Environments | Casual/Active Wear |

Ready to equip your workforce with superior safety and comfort? As a large-scale manufacturer, 3515 produces a comprehensive range of durable work footwear—including safety-toe boots and supportive shoes—for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality, reliable footwear tailored to your occupational needs. Contact us today to discuss your requirements and experience the 3515 difference!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

People Also Ask

- How is puncture resistance evaluated in footwear soles? Balance Protection, Comfort & Safety

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection

- What types of workplace hazards require protective footwear? Essential Guide for Workplace Safety

- What are the conditions faced by employees in meatpacking and poultry slaughter plants? Navigating Pervasive Slip Hazards

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection