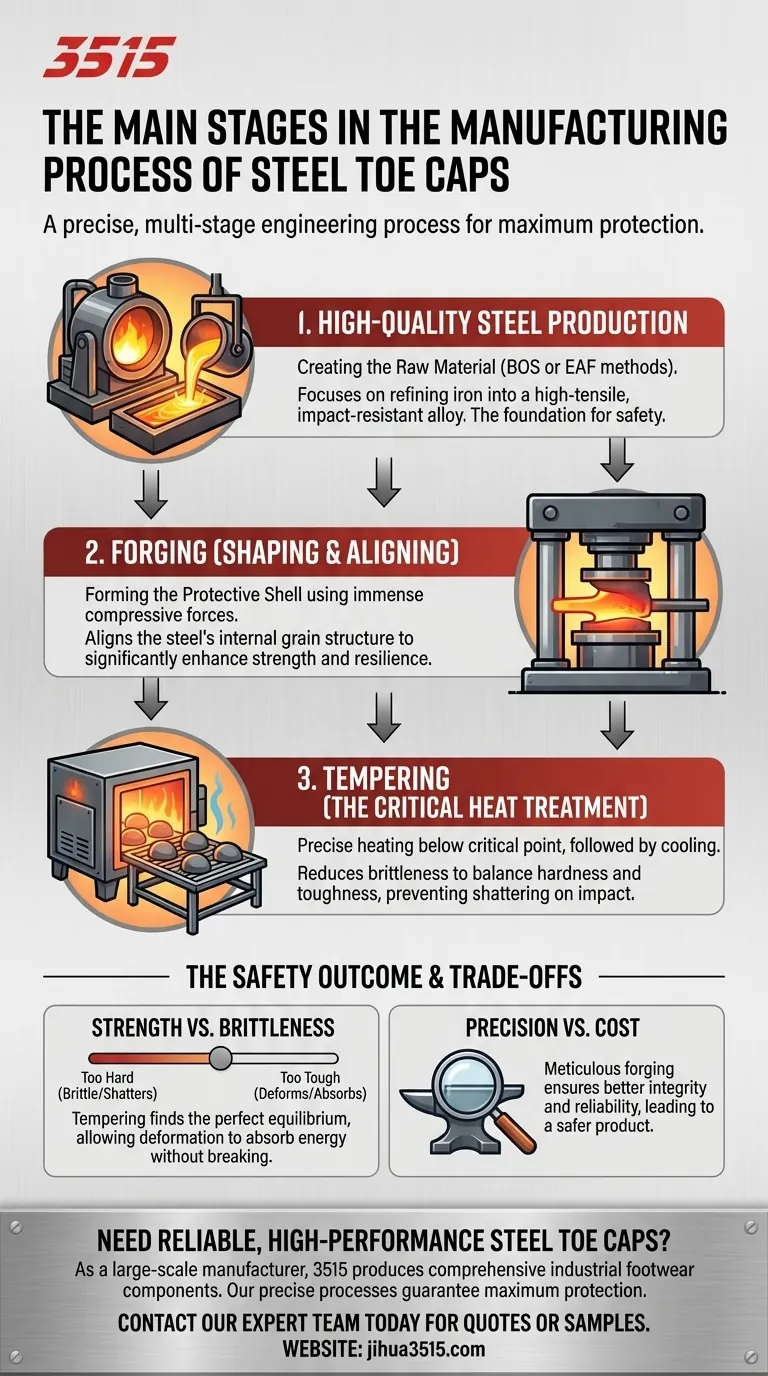

The manufacturing of a steel toe cap is a precise, multi-stage process designed to maximize its protective qualities. The core stages are steel production, where the raw material is created; forging, where the steel is shaped into a cap; and tempering, a critical heat treatment that gives the final product its necessary toughness and durability.

The goal of this process is not merely to shape a piece of metal. It is a carefully engineered sequence of forming and heat treatment designed to create a specific metallurgical structure that can absorb extreme impact and compression without shattering.

The Foundation: High-Quality Steel Production

Creating the Raw Material

The journey begins with the creation of high-quality steel. This is typically done using one of two primary industrial methods: the Basic Oxygen Steelmaking (BOS) process or the Electric Arc Furnace (EAF) method.

Both methods are focused on refining iron and other materials into a steel alloy with a specific, controlled composition suitable for high-stress applications.

Why the Right Steel Matters

The choice of steel is fundamental. Steel is selected for its inherent properties, including excellent impact resistance, high tensile strength, and durability.

This initial material provides the raw potential for a toe cap that can resist deformation under the immense force of compression or a sudden impact, which is the core requirement for its safety function.

Shaping and Aligning: The Forging Process

Forming the Protective Shell

Once the steel is produced, it must be shaped. Forging is the process of using compressive forces to shape the steel, often while it is hot, into the recognizable form of a toe cap.

This method is highly effective for producing parts that require significant strength. For premium safety footwear, this process can be particularly labor-intensive to ensure precision.

More Than Just a Shape

Crucially, forging does more than just form the cap. The immense pressure of the process refines the internal grain structure of the steel, aligning it to significantly enhance its strength and resilience against impact.

The Critical Final Step: Heat Treatment

Introducing Tempering

After forging, the steel is hard but can also be brittle. Tempering is a precise heat treatment process used to reduce this brittleness and enhance toughness.

The toe cap is heated to a specific temperature below its critical point, held there for a set duration, and then cooled.

The Balance of Hardness and Toughness

This is the most critical trade-off in the entire process. A component that is extremely hard is often brittle, meaning it could shatter on impact. A component that is tough can deform slightly to absorb energy without breaking.

Tempering optimizes this balance, intentionally trading a small amount of hardness for a significant gain in toughness.

The Direct Impact on Safety

A properly tempered steel toe cap will absorb the energy from a heavy impact by deforming, protecting the wearer. An untempered or improperly treated cap could fracture or shatter, completely failing its protective purpose.

Understanding the Trade-offs

Strength vs. Brittleness

The central trade-off is managed during tempering. The entire safety function of the toe cap relies on finding the perfect equilibrium where the steel is hard enough to resist being crushed but not so hard that it becomes brittle and shatters.

Precision vs. Cost

The reference to "labor-intensive" forging highlights another key consideration. While more automated processes exist, a meticulous forging process ensures better grain alignment and structural integrity, leading to a more reliable and safer final product, often at a higher cost.

What This Process Means for Your Safety

The manufacturing stages are directly linked to the performance of the final product. Understanding them helps you appreciate what makes a toe cap truly safe.

- If your primary focus is maximum impact protection: The integrity of the forging and tempering stages is what ensures the cap will absorb energy by deforming rather than shattering.

- If your primary focus is reliability and durability: The quality of the initial steel and the precision of the heat treatment are what prevent material fatigue and failure over time.

Ultimately, a steel toe cap's safety is not an accident of material but the direct result of intentional metallurgical engineering.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Steel Production | Basic Oxygen Steelmaking (BOS) or Electric Arc Furnace (EAF) | Creates high-quality steel alloy with high tensile strength and impact resistance. |

| 2. Forging | Shaping steel under high pressure and heat | Forms the cap and aligns the internal grain structure for enhanced strength. |

| 3. Tempering | Precise heat treatment below the critical temperature | Reduces brittleness and optimizes the balance of hardness and toughness for safety. |

Need reliable, high-performance steel toe caps for your safety footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every steel toe cap undergoes the precise forging and tempering processes detailed above, guaranteeing maximum impact protection and durability for the end-user.

Let's discuss your requirements: Contact our expert team today to get a quote or request samples.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What specific mechanical protections do industrial safety shoes provide in cable factories? Expert Guide for Max Safety

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why is Production Capacity (Mcap) a core parameter in safety shoe contracts? Optimize Supply and Mitigate Risk

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management