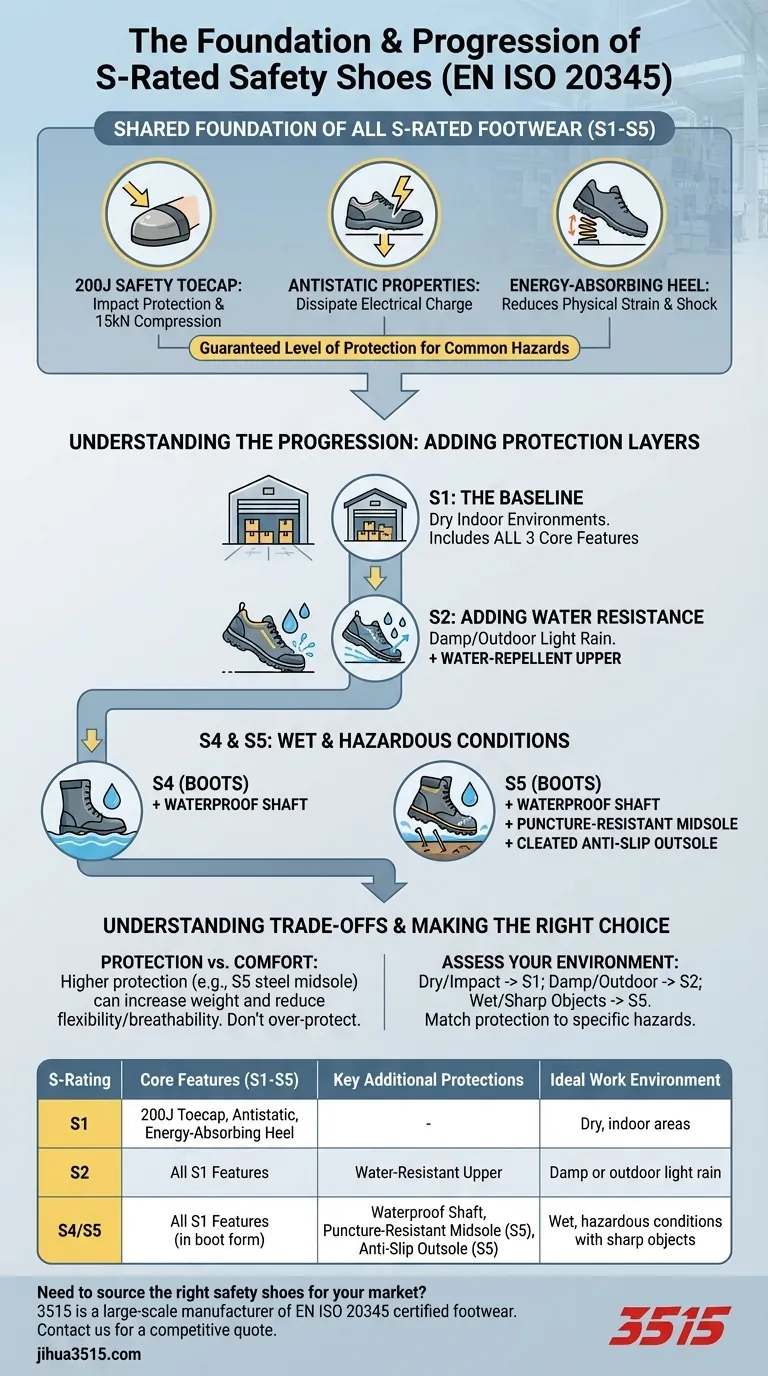

At their core, all safety shoes rated from S1 through S5 share three fundamental protective features mandated by the EN ISO 20345 standard. These common features are a safety toecap resistant to 200 joules of impact, antistatic properties to dissipate electrical charge, and an energy-absorbing heel to reduce physical strain.

The essential takeaway is that every "S" rated safety shoe begins with the same foundational protection against impact. The higher numbers do not signify "better" quality, but rather the addition of specific protections for hazards like water, punctures, or slipping.

The Foundation of All S-Rated Footwear

Every certified safety shoe, from the basic S1 to the comprehensive S5, is built upon a set of non-negotiable safety standards. This shared foundation ensures a guaranteed level of protection for common workplace hazards.

The 200-Joule Safety Toecap

This is the single most critical feature common to all ratings. The reinforced toecap is engineered to protect your toes from severe injury.

It must withstand a maximum impact energy of 200 joules, which is roughly equivalent to a 20 kg weight dropped from a height of one meter. It must also resist a compression force of 15,000 newtons.

Antistatic Properties

All S-rated shoes are designed to dissipate static electricity. This prevents the buildup of a static charge on your body, reducing the risk of electrostatic discharge which can damage sensitive electronic components or ignite flammable materials.

Energy-Absorbing Heel

This feature is designed for comfort and the long-term health of the wearer. The heel region is constructed to absorb impact energy as you walk, reducing the shock transmitted to your joints and spine.

Understanding the Progression: How Ratings Add Protection

Once the foundational safety features are met, the ratings ascend by adding layers of protection for increasingly specific or hazardous work environments.

S1: The Baseline for Dry Environments

An S1 shoe includes the three core features: a safety toecap, antistatic properties, and an energy-absorbing heel. It is the standard for indoor work where there is no risk of water exposure or sharp objects underfoot.

S2: Adding Water Resistance

S2 footwear includes all the features of S1 but adds a water-repellent upper. This keeps the wearer's feet dry in damp conditions or when working outdoors in light rain, making it suitable for a wider range of environments.

S4 and S5: For Wet and Hazardous Conditions

S4 and S5 ratings typically apply to waterproof boots, often made from rubber or polymeric materials. An S4 boot provides all the foundational protections within a fully waterproof shaft.

An S5 boot includes every feature of an S4, but adds two critical protections: a puncture-resistant midsole to protect against nails and other sharp objects, and a cleated, anti-slip outsole for enhanced traction.

Understanding the Trade-offs

Choosing the right safety shoe is not about picking the highest number, but about matching the protection to your specific work environment.

Protection vs. Comfort and Weight

Higher levels of protection, such as steel puncture-resistant midsoles, can add weight and reduce the flexibility of the shoe. A fully waterproof S5 boot will be far less breathable than an S1 shoe, which can be a major disadvantage in a hot, dry warehouse.

Over-Protection Is Inefficient

Wearing an S5 boot in an office or dry storage facility is unnecessary. The extra features provide no benefit for the risks present and may lead to discomfort over a long shift. Conversely, wearing an S1 shoe on a construction site is dangerously inadequate.

Extra Features Beyond the 'S' Rating

Manufacturers often add features that are not part of the core S-rating system. These can include composite (metal-free) toecaps, GORE-TEX waterproof liners for breathability, or specialized heat-resistant outsoles, which should be considered based on your specific needs.

Making the Right Choice for Your Goal

To select the correct footwear, you must first assess the specific hazards of your daily tasks.

- If your primary focus is work in dry, indoor environments with impact risk: An S1 shoe provides the essential, certified protection you need without unnecessary cost or weight.

- If your primary focus involves damp conditions or frequent outdoor work: The S2 rating is your minimum standard to ensure your feet remain dry and comfortable.

- If your primary focus is work in wet environments with a risk of sharp objects underfoot: The S5 rating offers the most comprehensive protection against both water penetration and puncture injuries.

Understanding this foundational system empowers you to choose safety footwear with confidence, ensuring you are neither under-protected nor burdened by features you don't need.

Summary Table:

| S-Rating | Core Features (S1-S5) | Key Additional Protections | Ideal Work Environment |

|---|---|---|---|

| S1 | 200J Toecap, Antistatic, Energy-Absorbing Heel | - | Dry, indoor areas |

| S2 | All S1 Features | Water-Resistant Upper | Damp or outdoor light rain |

| S4/S5 | All S1 Features (in boot form) | Waterproof Shaft, Puncture-Resistant Midsole (S5), Anti-Slip Outsole (S5) | Wet, hazardous conditions with sharp objects |

Need to source the right safety shoes for your market?

As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified footwear for distributors, brand owners, and bulk clients. Whether you need lightweight S1 shoes for warehouse teams or durable S5 boots for construction sites, our production capabilities encompass all types of safety shoes and boots to meet your exact requirements.

Contact us today to discuss your specific needs and get a competitive quote.

Visual Guide

Related Products

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- How do metatarsal guards enhance work shoe safety? Prevent Crushing Foot Injuries on the Job

- What is the primary function of reinforced steel toe caps in industrial safety shoes? Protect Workers from Stone Impacts

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- How do safety shoes with reinforced toe protection and puncture-resistant midsoles serve as a physical barrier?

- What are the advantages of KPU moulding material for labour protection shoes? Superior Durability & Comfort