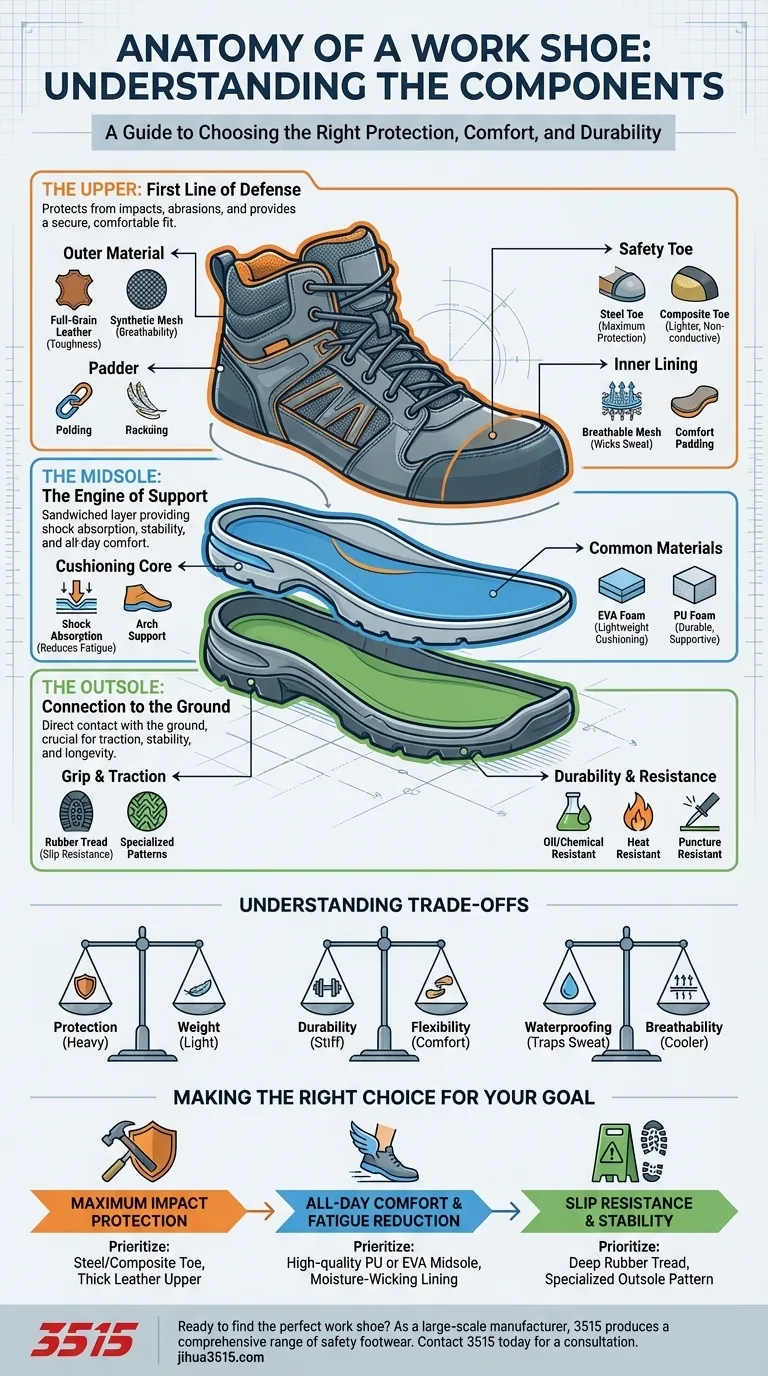

Understanding the anatomy of a work shoe is the first step to choosing the right pair for your needs. At its core, a work shoe is constructed from three primary sections: the Upper, which envelops and protects your foot; the Midsole, which provides cushioning and support; and the Outsole, which makes contact with the ground and provides grip.

A work shoe is a highly engineered system. While we can break it down into individual parts, its true value comes from how these components work together to deliver the specific protection, comfort, and durability required by your job.

The Upper: Your First Line of Defense

The upper is everything above the sole. Its primary job is to protect the foot from impacts, abrasions, and environmental hazards while providing a secure and comfortable fit.

The Outer Material

The choice of outer material dictates durability and breathability. Full-grain leather is a classic choice, prized for its exceptional toughness and ability to mold to the foot over time. Synthetic materials, like nylon mesh or microfiber, offer lighter weight and enhanced breathability.

The Safety Toe

This is the most critical safety feature for many jobs. A reinforced toe cap protects against compression and impact injuries. Steel toes offer maximum protection, while composite toes (made from carbon fiber, plastic, or Kevlar) are lighter and don't conduct electricity or cold.

The Inner Lining

The material on the inside of the shoe is designed for comfort and moisture management. Linings are often made from breathable mesh to help wick sweat away from the foot, reducing the risk of blisters and discomfort during long shifts.

The Midsole: The Engine of Support

Sandwiched between your foot and the outsole, the midsole is the shoe's shock absorption and support system. Its quality is directly responsible for how comfortable your feet feel at the end of the day.

The Cushioning Core

The midsole's main function is to absorb the impact of each step, reducing fatigue in your feet, legs, and back. A well-designed midsole provides a stable platform that supports the arch of your foot.

Common Materials

Midsoles are typically made from foams like EVA (ethylene vinyl acetate) or PU (polyurethane). EVA is lightweight and offers excellent cushioning, while PU is denser, heavier, and significantly more durable over the long term.

The Outsole: Your Connection to the Ground

The outsole is the part of the shoe that directly contacts the ground. Its design is critical for traction, stability, and longevity.

Grip and Traction

The material and tread pattern of the outsole determine its slip resistance. Rubber is the most common material due to its excellent grip and durability. Specialized patterns are designed to channel away water or provide a better hold on uneven surfaces.

Durability and Resistance

For many industrial environments, the outsole must resist specific hazards. Outsoles can be engineered to be resistant to oil, chemicals, heat, or punctures, providing a vital layer of protection from the ground up.

Understanding the Trade-offs

Selecting a work shoe involves balancing competing priorities. No single shoe excels at everything, and the ideal choice depends on your specific work environment.

Protection vs. Weight

More protective features, like steel toes and thick rubber outsoles, add significant weight. This can increase fatigue over a long day compared to lighter-weight composite toes and EVA midsoles.

Durability vs. Flexibility

Highly durable materials like polyurethane and thick leather are built to last but can feel stiff initially. More flexible materials may offer immediate comfort but often wear out more quickly under harsh conditions.

Waterproofing vs. Breathability

A fully waterproof boot is excellent at keeping water out, but it can also trap sweat in. A highly breathable shoe will keep your feet cooler and drier from sweat but offers less protection from external moisture.

Making the Right Choice for Your Goal

By understanding how these components function, you can inspect a potential work shoe and determine if it meets the demands of your job.

- If your primary focus is maximum impact protection: Prioritize a shoe with a certified steel or composite safety toe and a robust upper made from thick leather.

- If your primary focus is all-day comfort and fatigue reduction: Pay close attention to a high-quality PU or thick EVA midsole and a moisture-wicking inner lining.

- If your primary focus is slip resistance: The outsole is your most critical component; look for a deep, well-defined tread pattern made from high-traction rubber.

Choosing the right work shoe is an investment in your safety and daily well-being.

Summary Table:

| Component | Primary Function | Key Features & Materials |

|---|---|---|

| Upper | Protects the foot and provides a secure fit. | Safety toe (steel/composite), outer material (leather/synthetic), inner lining. |

| Midsole | Provides cushioning, shock absorption, and arch support. | Cushioning core made from EVA (lightweight) or PU (durable). |

| Outsole | Offers traction, stability, and resistance to ground hazards. | Rubber material with specialized tread patterns for grip. |

Ready to find the perfect work shoe for your needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, engineered with the precise balance of protection, comfort, and durability your workforce requires.

Let us help you make the right investment in safety and comfort.

Contact 3515 today for a consultation to discuss your specific requirements and explore our extensive catalog.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries