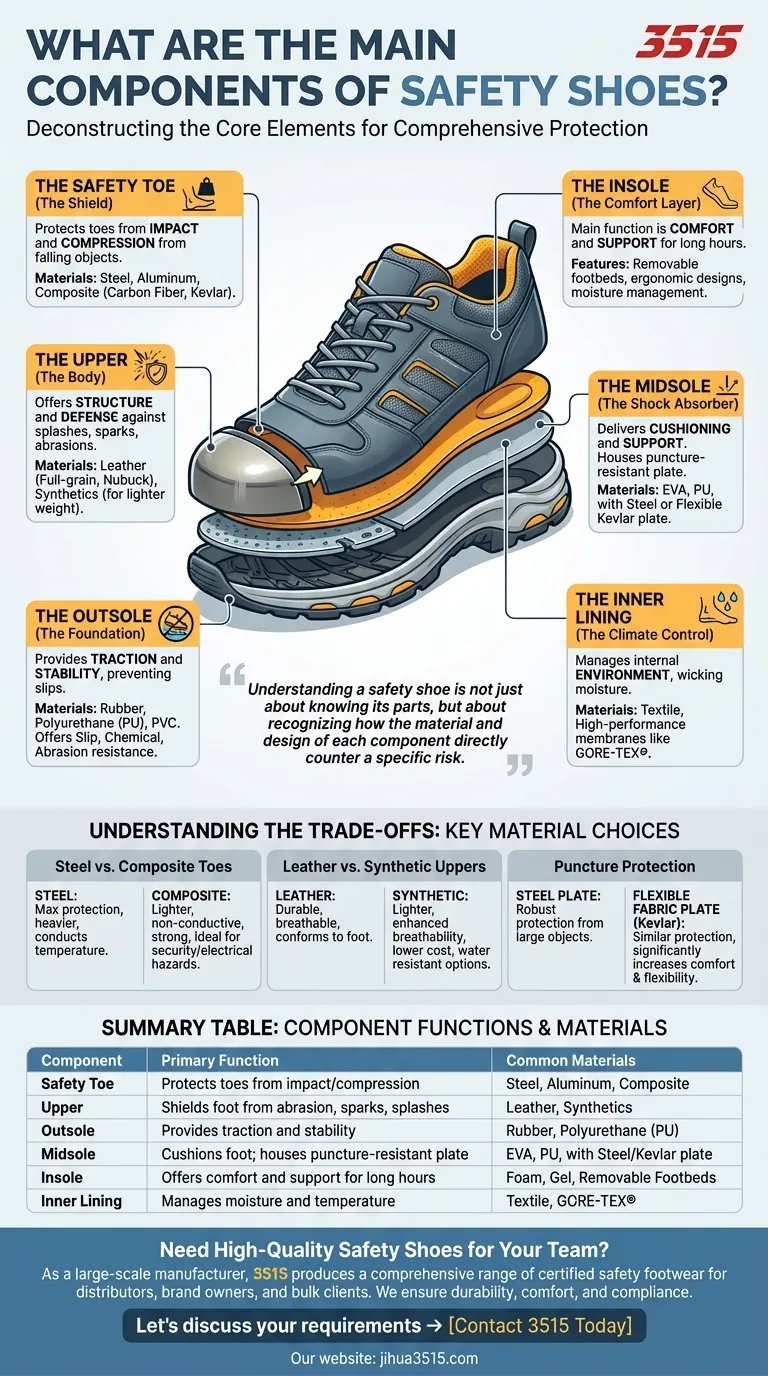

At their core, safety shoes consist of six primary components. These are the safety toe, upper, inner lining, outsole, midsole, and insole. Each part is engineered with specific materials to work in concert, providing comprehensive protection against workplace hazards.

Understanding a safety shoe is not just about knowing its parts, but about recognizing how the material and design of each component directly counter a specific risk in your work environment.

Deconstructing the Safety Shoe: The Core Components

To truly appreciate how a safety shoe protects you, we must examine the function of each of its fundamental parts. The effectiveness of the shoe is determined by the quality and synergy of these six elements.

The Safety Toe (The Shield)

This is the most recognized feature of a safety shoe. Its sole purpose is to protect your toes from impact and compression caused by falling objects or heavy machinery.

The material used for the toe cap is a critical choice. Common options include steel, aluminum, and composite materials like carbon fiber or Kevlar.

The Upper (The Body)

The upper is the entire part of the shoe that covers the top of your foot. It provides the shoe's structure and offers the first line of defense against splashes, sparks, and abrasions.

Materials range from various types of leather (full-grain, nubuck) for durability to synthetics for lighter weight or specialized resistance.

The Outsole (The Foundation)

The outsole is the layer that makes direct contact with the ground. Its primary job is to provide traction and stability, preventing slips and falls.

It is typically made from materials like rubber, Polyurethane (PU), or PVC, each offering different levels of slip, chemical, and abrasion resistance. Some outsoles also provide puncture resistance.

The Midsole (The Shock Absorber)

Located between the insole and the outsole, the midsole delivers cushioning and support. Crucially, it can also house a puncture-resistant plate made of steel or flexible materials like Kevlar.

This plate protects the sole of your foot from sharp objects like nails or metal shards on the ground.

The Insole (The Comfort Layer)

The insole, or footbed, is the layer your foot rests on directly. While its main function is comfort and support for long hours of wear, it also plays a role in moisture management.

Modern insoles are often removable and designed with ergonomic features to reduce foot fatigue.

The Inner Lining (The Climate Control)

The lining manages the environment inside the shoe. It wicks moisture away from the foot to keep it dry and comfortable.

High-performance linings, such as GORE-TEX, provide a waterproof yet breathable barrier, essential for working in wet conditions.

Understanding the Trade-offs: Key Material Choices

The materials used in each component dictate the shoe's performance, weight, and ideal use case. Choosing the right shoe means understanding these critical differences.

Steel vs. Composite Toes

Steel toes offer maximum protection and have been the industry standard for decades. However, they are heavier and conduct temperature.

Composite toes are lighter, do not conduct electricity or temperature, and can be just as strong, making them ideal for environments where metal detectors are present or electrical hazards are a concern.

Leather vs. Synthetic Uppers

Full-grain leather uppers are exceptionally durable, breathable, and conform to the foot over time. They are excellent for rugged construction or manufacturing environments.

Synthetic materials like nylon mesh can offer lighter weight, enhanced breathability, and specific properties like water resistance at a lower cost, suiting less abrasive work conditions.

Puncture Protection: Steel vs. Fabric Plates

A steel plate in the midsole offers robust, reliable protection against punctures from large objects like nails.

Flexible fabric plates, often made of materials like Kevlar, provide similar protection but allow the shoe to bend more naturally with the foot, significantly increasing comfort and reducing fatigue.

Making the Right Choice for Your Environment

Your specific workplace hazards must dictate your choice. Assess your environment first, then select a shoe with components designed to mitigate those risks.

- If your primary focus is protection from falling objects and heavy equipment: Prioritize a shoe with a certified steel or composite safety toe.

- If your primary focus is preventing slips on wet or oily surfaces: Scrutinize the outsole material and tread pattern for high slip-resistance ratings.

- If your primary focus is working around live electricity: Ensure your footwear is rated for Electrical Hazard (EH) protection, which requires a non-conductive composite toe and outsole.

- If your primary focus is comfort during long shifts on hard floors: Look for a supportive insole, a shock-absorbing midsole, and a lighter overall shoe weight.

Ultimately, the right safety shoe is a crucial piece of personal protective equipment designed to bring you home safely.

Summary Table:

| Component | Primary Function | Common Materials |

|---|---|---|

| Safety Toe | Protects toes from impact/compression | Steel, Aluminum, Composite |

| Upper | Shields foot from abrasion, sparks, splashes | Leather, Synthetics |

| Outsole | Provides traction and stability | Rubber, Polyurethane (PU) |

| Midsole | Cushions foot; houses puncture-resistant plate | EVA, PU, with Steel/Kevlar plate |

| Insole | Offers comfort and support for long hours | Foam, Gel, Removable Footbeds |

| Inner Lining | Manages moisture and temperature | Textile, GORE-TEX® |

Need High-Quality Safety Shoes for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise components discussed here to mitigate your specific workplace risks.

We ensure durability, comfort, and compliance with international safety standards.

Let's discuss your requirements → Contact 3515 Today

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- How does the integration of physiological sensors like SpO2 and HRV improve smart safety footwear functionality?

- What additional feature in safety footwear can help absorb impact before the toe cap is struck? | Discover the Toe Bumper

- What are the features of security guard safety boots for women vs. men? The Ultimate Guide to Anatomical Fit

- What additional consideration is mentioned if protective footwear is electric shock resistant? Employer's Financial Responsibility

- What are the general characteristics of motorcycle boots? Essential Safety Features Explained

- What factors influence employer decisions on paying for non-specialty safety shoes? Maximize ROI and Safety

- What are the characteristics of natural leather used in labour protection shoes? Unmatched Comfort & Durability

- What are the key differences between Class I and Class II safety shoes? Choose the Right Protection for Your Job