The materials in a safety trainer are a carefully engineered system designed to protect your feet without sacrificing comfort. Typically, the uppers are made from breathable materials like mesh or nylon, the protective toe caps are made from lightweight composite materials, and the outsoles use rubber or TPU for superior grip and durability.

The choice of materials in a safety trainer is never arbitrary. It is a deliberate balance between targeted protection, all-day comfort, and resilience against the specific hazards of a work environment.

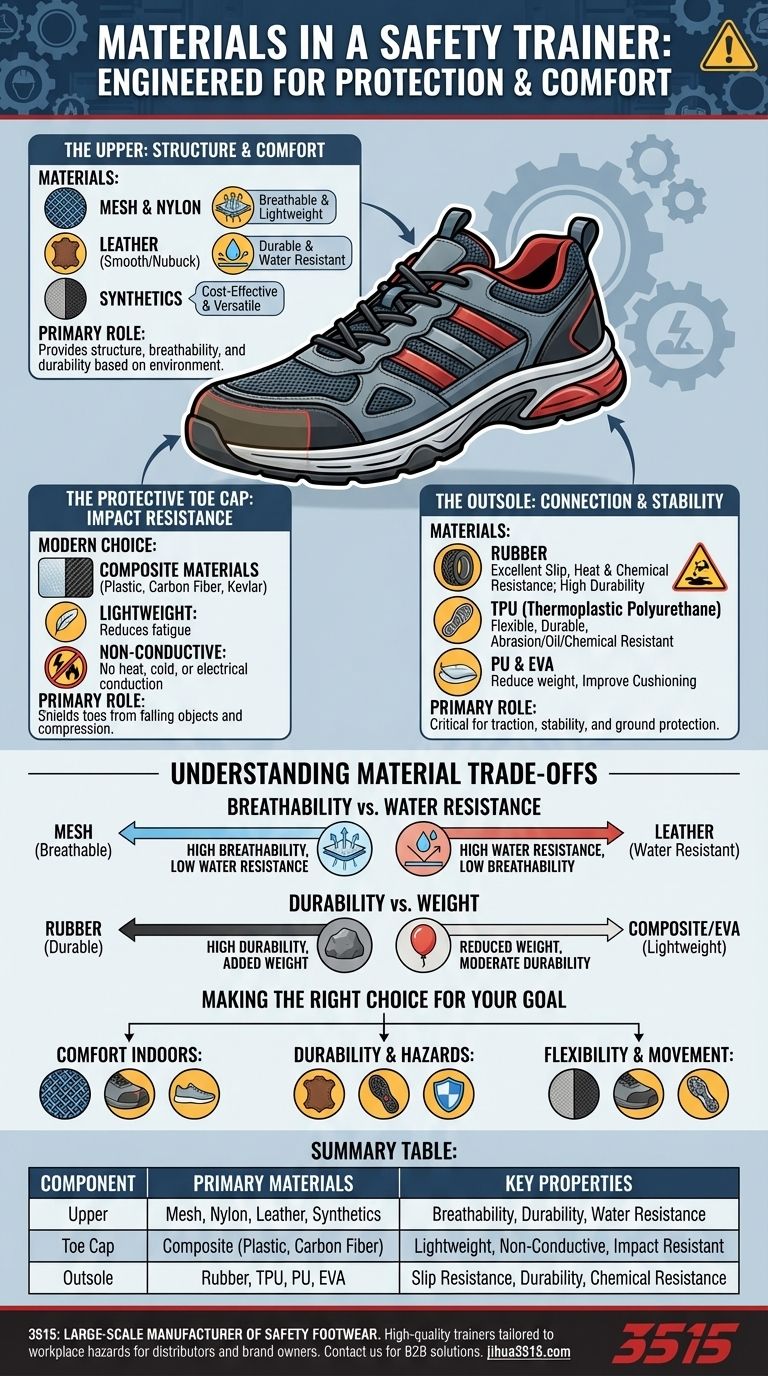

Deconstructing the Safety Trainer: A Component-by-Component Look

Understanding a safety trainer requires looking at its three primary sections: the upper, the protective toe cap, and the outsole. Each uses different materials selected for a specific function.

The Upper: Balancing Breathability and Durability

The upper is the part of the shoe that covers your foot. Its primary role is to provide structure and comfort.

Common materials include textiles like mesh and nylon, which are highly valued for being lightweight and breathable, making them ideal for indoor or warm environments.

For more demanding conditions, various types of leather (smooth, nubuck) are used. Leather offers superior durability and natural resistance to water and abrasion.

Synthetic materials are also frequently used, offering a cost-effective and versatile alternative that can be engineered for specific properties like cleanability or water resistance.

The Protective Toe Cap: Modern Impact Resistance

The defining feature of a safety trainer is its protective toe cap, designed to shield the toes from falling objects and compression.

While steel was the traditional choice, modern trainers increasingly use composite toe caps. These are made from non-metal materials like plastic, carbon fiber, or Kevlar.

The primary advantages of composite caps are their light weight, which reduces fatigue, and the fact that they do not conduct heat, cold, or electricity.

The Outsole: Your Connection to the Ground

The outsole is the layer that makes direct contact with the ground, and its material composition is critical for safety and stability.

Rubber is a dominant material due to its excellent frictional properties, which provide outstanding slip resistance (traction) on various surfaces. It is also known for its high resistance to wear, heat, and chemicals like acids.

TPU (Thermoplastic Polyurethane) is another popular choice, prized for its flexibility, durability, and resistance to abrasion, oil, and chemicals.

Other materials like Polyurethane (PU) and EVA (Ethylene-vinyl acetate) are also used, often to reduce weight and improve cushioning.

Understanding the Material Trade-offs

No single material is perfect for every situation. Choosing the right safety trainer means understanding the inherent compromises between different material properties.

Breathability vs. Water Resistance

Highly breathable uppers, like mesh, are excellent for keeping feet cool and dry from sweat in indoor settings. However, they offer almost no protection from external moisture.

Conversely, a leather upper provides much better water resistance but is less breathable and can become heavy and warm.

Durability vs. Weight

The most durable materials are often the heaviest. A thick rubber outsole can withstand incredible punishment but adds significant weight to the shoe.

Materials like composite for the toe cap and EVA in the midsole are used specifically to reduce overall weight, which enhances comfort over a long day but may offer less abrasion resistance than their heavier counterparts.

Making the Right Choice for Your Goal

Selecting the correct materials depends entirely on your work environment and daily tasks.

- If your primary focus is all-day comfort indoors: Look for trainers with breathable mesh uppers, a lightweight composite toe cap, and a cushioned PU or EVA sole.

- If your primary focus is durability and hazard resistance: Prioritize trainers with leather uppers and a robust rubber outsole to withstand chemicals, heat, and abrasion.

- If your primary focus is flexibility and frequent movement: A trainer with synthetic uppers, a composite toe, and a flexible TPU outsole provides an excellent modern balance of protection and agility.

Ultimately, the best safety trainer is one whose materials are precisely matched to the demands of your specific workplace.

Summary Table:

| Component | Primary Materials | Key Properties |

|---|---|---|

| Upper | Mesh, Nylon, Leather, Synthetics | Breathability, Durability, Water Resistance |

| Toe Cap | Composite (Plastic, Carbon Fiber) | Lightweight, Non-Conductive, Impact Resistant |

| Outsole | Rubber, TPU, PU, EVA | Slip Resistance, Durability, Chemical Resistance |

Need high-quality safety trainers tailored to your specific workplace hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the right materials for durability, comfort, and protection.

Contact us today to discuss your requirements and discover how we can deliver the perfect safety footwear solution for your customers.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- How does the anti-smashing feature of safety shoes protect technicians? Expert Guide to Ladder Setup Safety

- What are the technical advantages of integrating flexible sensing technology and FSR into footwear? Boost Smart Safety

- Why are work shoes important beyond being a fashion accessory? Essential for Safety & Performance

- What are the disadvantages of using fabrics in safety shoe uppers? Balancing Comfort with Durability

- What industries commonly require protective footwear? Essential Foot Safety for High-Risk Sectors

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What are the advantages of composite toe boots over steel or alloy toe boots? Lightweight, Non-Conductive Safety

- Why might safety toe shoes require a larger size? Ensure a Safe and Comfortable Fit