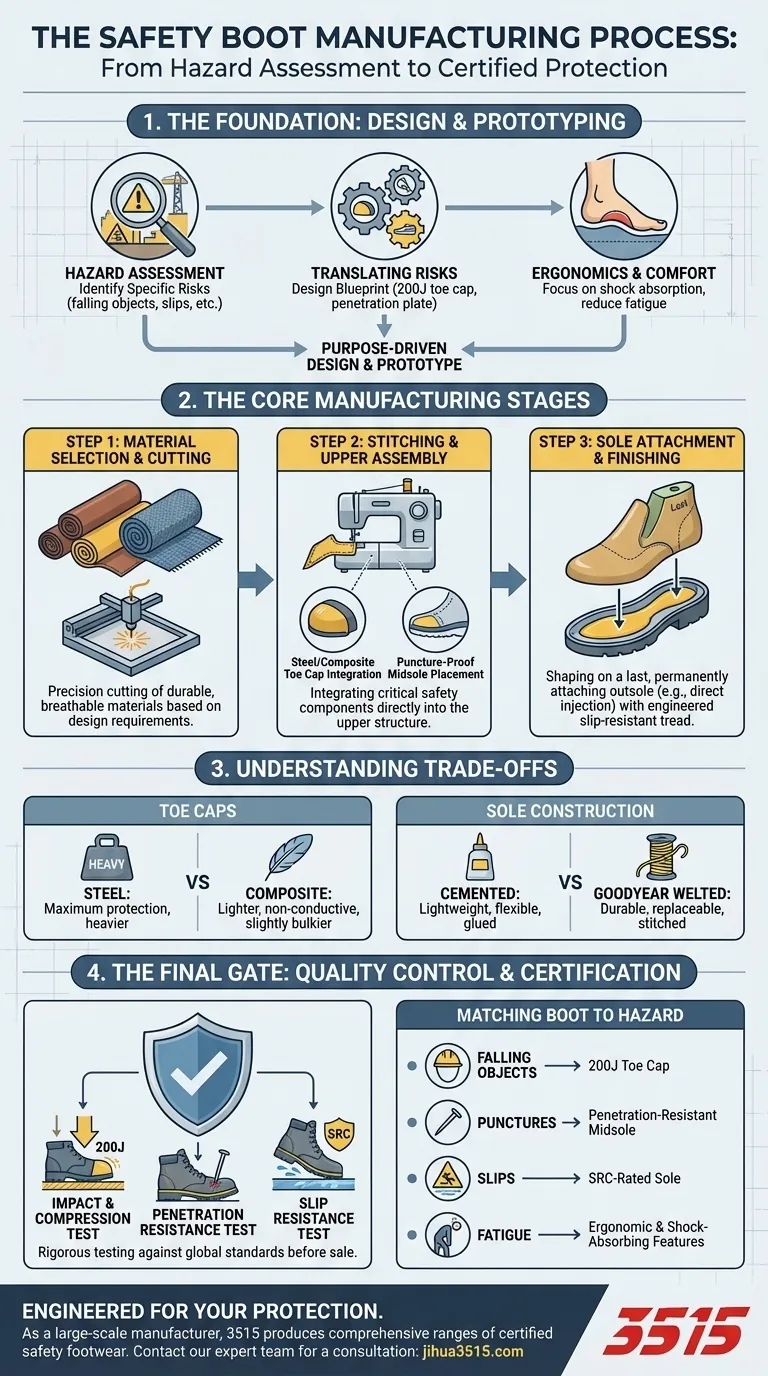

The manufacturing of safety boots is a multi-stage process that transforms raw materials into certified protective equipment. It begins with a purpose-driven design and prototyping phase, moves to the precision cutting of materials, continues through a complex assembly where key protective components are integrated, and concludes with rigorous quality control to ensure every pair meets stringent safety standards.

The creation of a safety boot is not merely assembly; it is a systematic process of engineering a solution to a specific set of workplace hazards. Every step, from material selection to the final quality check, is a direct response to a potential risk, ensuring the final product provides certified, reliable protection.

The Foundation: From Hazard Assessment to Design

The entire manufacturing process begins not in the factory, but with an analysis of the environment where the boot will be used.

Identifying the Specific Risks

Before any design is sketched, a thorough hazard assessment is conducted. This evaluation determines the specific dangers workers face, such as falling objects, sharp materials underfoot, slippery surfaces, or electrical hazards.

Translating Risks into Features

The results of this assessment form the design blueprint. A risk of falling tools dictates a 200-joule protective toe cap. A risk of nails on the floor demands a penetration-resistant midsole. This ensures the boot is purpose-built for its intended environment.

Ergonomics and Wearer Comfort

A safe boot that is too uncomfortable to wear properly is not safe at all. The design phase incorporates ergonomics, focusing on features like arch support and shock absorption in the heel to reduce fatigue for those who stand for long periods.

The Core Manufacturing Stages

Once the design is finalized and prototyped, the physical production begins with precision and care.

Step 1: Material Selection and Cutting

High-quality materials like leather or advanced synthetic textiles are selected based on the design requirements for durability, breathability, and resistance to elements like water or oil. These materials are then laid out and cut into the various pieces of the boot's upper with extreme precision.

Step 2: Stitching and Upper Assembly

The cut pieces are meticulously stitched together to form the boot's upper. During this stage, critical safety components are integrated directly into the structure. The protective toe cap (steel or composite) is secured in the front, and the puncture-proof midsole is placed in the base.

Step 3: Sole Attachment and Finishing

The completed upper is stretched over a foot-shaped mold called a "last" to give it its final shape. The outsole is then permanently attached using methods like direct injection molding or high-strength bonding. The sole's material and tread pattern are engineered specifically to provide slip resistance and durability.

Understanding the Trade-offs

Choosing the right safety boot involves understanding the key differences in its core components.

Steel vs. Composite Toe Caps

Steel caps are the traditional standard, offering maximum protection against impact and compression. Composite caps are lighter, do not conduct heat or cold, and are ideal for metal-free environments, though they can sometimes be slightly bulkier to achieve the same safety rating.

Sole Construction

The method used to attach the sole affects the boot's durability and flexibility. A cemented sole (glued) is lightweight and flexible, while a Goodyear welted sole (stitched) is exceptionally durable and can be replaced, extending the boot's life.

The Myth of "One-Size-Fits-All" Safety

No single boot is perfect for every job. A boot designed with heat and fuel resistance for an oil rig is fundamentally different from a lightweight, anti-static boot designed for an electronics assembly plant. The initial hazard assessment is non-negotiable.

The Final Gate: Quality Control and Certification

Before a boot can be sold, it must pass a battery of tests to prove it meets global or regional safety standards.

Testing for Impact and Compression

The toe cap is subjected to a 200-joule impact test (equivalent to a 20kg weight dropped from about 1 meter) and a compression test to ensure it protects the wearer's foot.

Verifying Penetration Resistance

The midsole is tested to confirm it can resist puncture from a sharp object, like a nail, under significant force.

Certifying Slip Resistance

The sole is tested on different surfaces with various contaminants to earn a slip-resistance rating. SRC is the highest rating, indicating the boot has passed tests on both ceramic tile with soapy water (SRA) and steel with glycerol (SRB).

Matching the Boot to the Hazard

Use the intended work environment as your primary guide to select the right features.

- If your primary focus is protection from falling objects: Look for boots with a certified 200-joule steel or composite toe cap.

- If your primary focus is preventing underfoot punctures: Ensure the boot features a penetration-resistant midsole.

- If your primary focus is avoiding slips on wet or oily surfaces: Check the sole's rating and choose SRC for the highest level of tested slip resistance.

- If your primary focus is all-day comfort and preventing fatigue: Prioritize features like shock-absorbing heels, anti-static properties, and ergonomic insoles.

Understanding this manufacturing journey empowers you to see a safety boot not as a commodity, but as a critical piece of engineered equipment designed for your protection.

Summary Table:

| Key Manufacturing Stage | Primary Focus | Key Outputs |

|---|---|---|

| Foundation: Design & Prototyping | Hazard Assessment & Ergonomics | Purpose-built design blueprint, Prototype |

| Core Stage 1: Material Cutting | Precision & Material Selection | Precisely cut leather/textile pieces for boot upper |

| Core Stage 2: Upper Assembly | Integration of Safety Components | Stitched upper with integrated toe cap & midsole |

| Core Stage 3: Sole Attachment | Durability & Slip Resistance | Boot shaped on a last, outsole permanently attached |

| Final Gate: Quality Control | Certification to Safety Standards | Boots tested for impact, compression, puncture, and slip resistance |

Need Safety Boots Engineered for Your Specific Hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, from designs with 200-joule steel toe caps and puncture-resistant midsoles to models with SRC-rated slip-resistant soles.

We transform your specific hazard assessment into reliable, certified protective equipment. Let's discuss your requirements and how we can deliver the perfect safety solution for your workforce.

Contact our expert team today for a consultation

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection

- What are steel toe boots and how are they designed? Essential Guide to Industrial Footwear Safety

- What additional safety features do steel toe work boots often include? Beyond the Steel Toe Cap

- Why is it important to wear steel toe work boots? Maximum Impact Protection for Hazardous Work

- How do women's safety toe work boots protect against foot injuries? A Complete Guide to Workplace Foot Safety