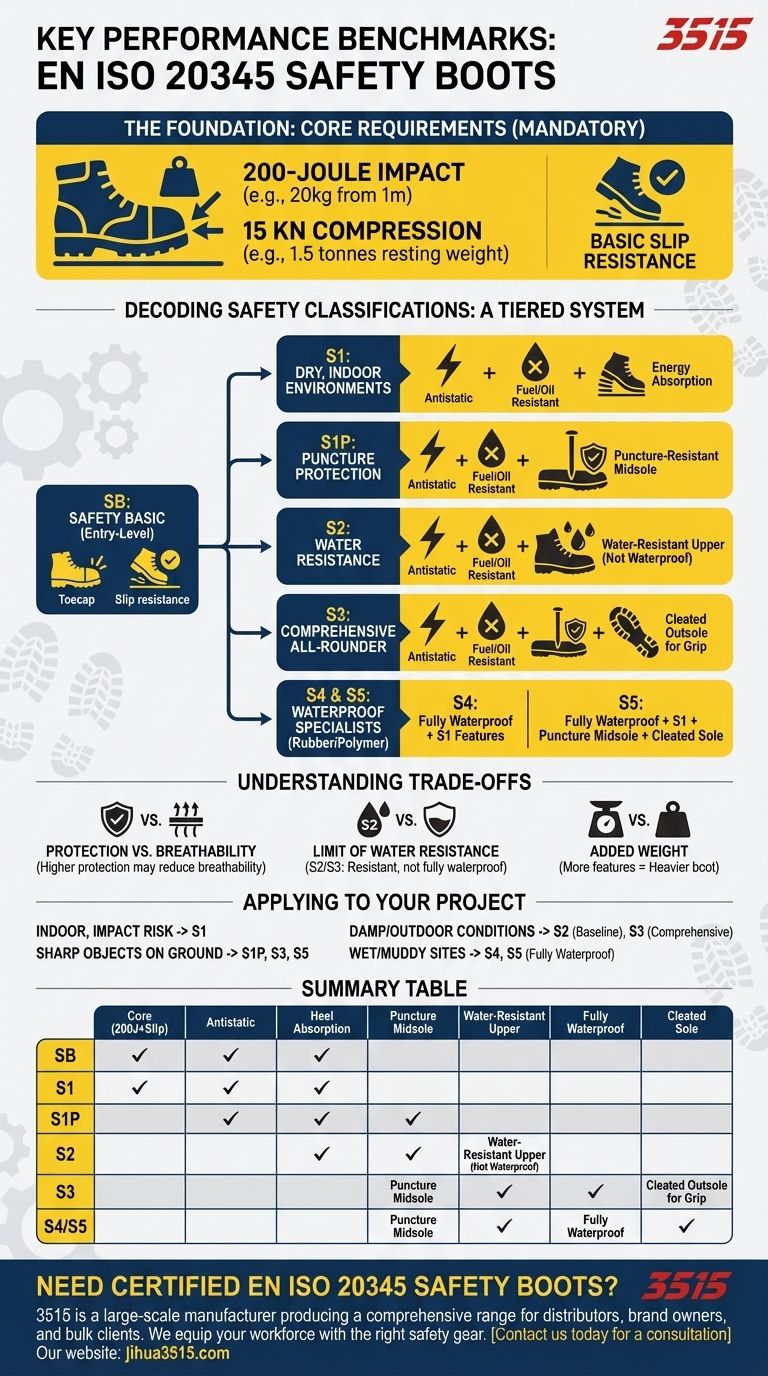

The single most important benchmark set by the EN ISO 20345 standard is that a safety boot's toecap must withstand a 200-joule impact and a 15 kilonewton (KN) compression force. Beyond this core requirement, the standard uses a classification system (S1, S2, S3, etc.) to define additional performance benchmarks for hazards like sole puncture, water, slips, and static electricity.

The EN ISO 20345 standard is not a single benchmark but a tiered system. It establishes a mandatory minimum for toe protection and then adds layers of specific protections—from puncture resistance to waterproofing—to match the unique risks of different work environments.

The Foundation of Safety: Core Requirements

Every boot certified under EN ISO 20345 must pass two critical, non-negotiable tests that form the baseline for all safety footwear.

The 200-Joule Toecap Standard

The defining feature of this standard is its strict requirement for toe protection. The protective toecap, whether made of steel, composite, or aluminum, must be able to absorb an impact of 200 joules.

This is equivalent to dropping a 20kg (44 lbs) weight from a height of one meter.

Furthermore, the toecap must also resist a compression force of 15KN, which is roughly equivalent to 1.5 tonnes of weight resting on the toe area.

Basic Slip Resistance

In addition to impact protection, all certified footwear must meet a minimum standard for slip resistance on a specified test surface. This ensures a fundamental level of grip for general use.

Decoding the Safety Classifications

The true utility of the standard comes from its classification system. Each level builds upon the previous one, adding protections for specific hazards. The rating is typically marked on the boot's tongue or label.

SB: Safety Basic

This is the entry-level classification. An SB-rated boot meets the minimum requirements: a 200-joule toecap and basic slip resistance. It may have an open back, like a clog.

S1: For Dry, Indoor Environments

An S1 boot builds upon the SB foundation by adding several key features.

- Antistatic properties to dissipate static electricity.

- Fuel and oil resistant outsole.

- Energy absorption in the heel region for comfort and shock reduction.

S1P: Protection From Punctures

The S1P rating includes all the features of an S1 boot, plus a crucial addition: a puncture-resistant midsole. This protects the foot from sharp objects like nails or screws penetrating from below.

S2: Adding Water Resistance

An S2 boot has all the protective features of S1, but with an upper that is resistant to water penetration and absorption. This makes it suitable for working in damp or wet conditions.

S3: The Comprehensive All-Rounder

S3 is one of the most common and comprehensive ratings. It combines the features of an S2 boot (water resistance) with the puncture-resistant midsole of an S1P boot. It also typically features a cleated or studded outsole for enhanced grip.

S4 & S5: The Waterproof Specialists

These classifications are typically for boots made entirely of rubber or polymer, like wellingtons.

- S4: Fully waterproof and leak-proof, with all the basic S1 protections (toecap, antistatic, heel energy absorption, fuel resistance).

- S5: The highest level of protection. It has all the features of an S4 boot but adds a puncture-resistant midsole and a cleated outsole.

Understanding the Trade-offs

Selecting the right boot involves balancing protection with other factors. A higher classification is not always better if it doesn't match your environment.

Protection vs. Breathability

Features like water-resistant membranes (found in S2 and S3 boots) or fully waterproof rubber uppers (S4 and S5) will inherently reduce breathability. In a hot, dry environment, an S1 boot will be far more comfortable.

The Limit of "Water Resistance"

It is critical to distinguish between "water-resistant" and "waterproof." S2 and S3 boots will keep feet dry from splashes and in damp conditions, but they are not designed for prolonged immersion. For that, you need a fully waterproof S4 or S5 boot.

Added Weight

Each additional protective feature, such as a steel midsole for puncture resistance, can add weight to the boot. While modern materials have mitigated this, a fully-featured S3 or S5 boot will generally be heavier than a basic S1.

How to Apply This to Your Project

Your choice should be dictated by a clear risk assessment of your work environment.

- If your primary focus is working indoors with impact risk: An S1 boot provides the necessary toecap protection and comfort features for dry environments.

- If you face risks from sharp objects on the ground (nails, screws): You must select a rating with midsole protection, such as S1P, S3, or S5.

- If you work in damp conditions or outdoors: S2 offers a good baseline for water resistance, but S3 provides more comprehensive protection that includes puncture resistance.

- If you need fully waterproof protection in wet or muddy sites: S4 or S5 boots made from polymer or rubber are the only correct choice.

Understanding these benchmarks empowers you to select footwear that provides optimal protection for your specific tasks.

Summary Table:

| Classification | Core Protection (200J Toecap + Slip Resistance) | Key Additional Features | Ideal For |

|---|---|---|---|

| SB | ✓ | Basic safety features | Entry-level, dry indoor areas |

| S1 | ✓ | Antistatic, fuel/oil resistant sole, heel absorption | Dry, indoor workshops |

| S1P | ✓ | S1 features + Puncture-resistant midsole | Indoor areas with sharp object risks |

| S2 | ✓ | S1 features + Water-resistant upper | Damp or wet indoor/outdoor conditions |

| S3 | ✓ | S2 features + Puncture-resistant midsole & cleated sole | Comprehensive protection for varied sites |

| S4/S5 | ✓ | Fully waterproof (polymer/rubber), S1 features (+ puncture/cleated for S5) | Wet/muddy sites requiring waterproofing |

Need Safety Boots That Meet EN ISO 20345 Standards?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the right protection for your specific work environment.

Let us help you equip your workforce with the right safety gear.

Contact us today for a consultation to discuss your requirements and benefit from our manufacturing expertise.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What is an OSHA approved shoe? The Truth About Compliant Safety Footwear

- How do professional safety shoes contribute to operational efficiency? Boost Logistics Productivity and Safety

- What role does a heel counter play in safety footwear? Unlock Stability, Safety, and Comfort

- Why are C-shaped rubber bands and shoe cover designs necessary when integrating industrial safety shoes with exoskeletons?

- What materials are commonly used for outsoles in safety boots? A Guide to Durability, Grip, and Comfort

- What materials are used in alloy toe shoes? A Guide to Lightweight Safety Footwear

- What are the primary protective functions of industrial-grade safety shoes? Essential Occupational Safety Guide

- How do metatarsal guards enhance work shoe safety? Prevent Crushing Foot Injuries on the Job