At their core, alloy toe shoes use a protective cap made from a blend of lightweight metals, most commonly aluminum and titanium. This construction allows them to provide certified impact and compression protection that is significantly lighter than traditional steel, reducing foot fatigue over a long day.

The key takeaway is that while the "alloy" refers specifically to the lightweight metal cap (like aluminum or titanium), the materials used for the rest of the shoe—such as leather, synthetics, or canvas—are what truly define its overall function, style, and suitability for your specific work environment.

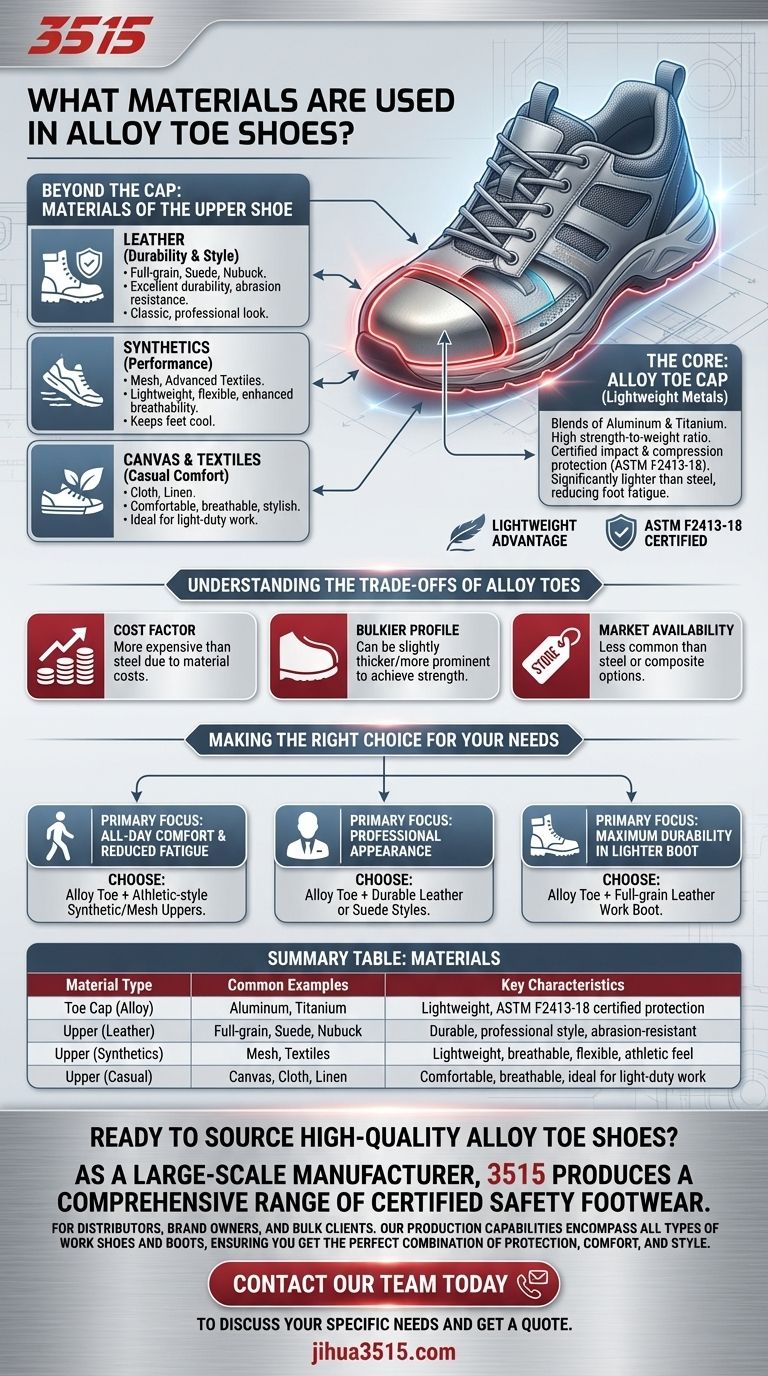

What "Alloy" Really Means in a Safety Toe

An alloy toe cap is engineered to provide protection without the weight penalty of steel. This makes them a popular choice for professionals who are on their feet all day but still require certified safety footwear.

The Core Metals: Aluminum and Titanium

The term "alloy" simply means a mixture of metals. In safety footwear, this almost always refers to a formulation based on aluminum or titanium. These metals are chosen for their high strength-to-weight ratio.

The Lightweight Advantage

This is the primary benefit of alloy toes. By using lighter metals, manufacturers can create a safety shoe that feels more like a standard sneaker or boot, significantly reducing fatigue and improving overall comfort.

Meeting and Exceeding Safety Standards

Despite being lighter, alloy safety toes are fully compliant with industry safety standards. They are rated to meet the ASTM F2413-18 standard for impact and compression resistance, offering the same level of protection as their steel and composite counterparts.

Beyond the Cap: Materials of the Upper Shoe

The toe cap is only one component. The materials used for the main body of the shoe, known as the "upper," determine its durability, breathability, and appearance.

Leather for Durability and Style

Leather and its variations like suede or nubuck are common in work boots and business casual safety shoes. They offer excellent durability and resistance to wear, providing a classic, professional look.

Synthetics for Performance

Many modern, athletic-style safety shoes use synthetic materials and mesh panels. These uppers are lightweight, flexible, and enhance airflow, which helps keep feet cool and dry during intense activity.

Canvas and Textiles for Casual Comfort

For less demanding environments, casual safety shoes may use materials like canvas, cloth, or linen. These offer a comfortable, breathable, and stylish alternative for light-duty work.

Understanding the Trade-offs of Alloy Toes

While excellent, alloy toes are not the perfect solution for every situation. Understanding their specific characteristics is crucial for making the right choice.

The Cost Factor

Alloy toe shoes tend to be more expensive than their steel toe equivalents. The higher cost of materials like aluminum and titanium is reflected in the final price of the shoe.

Bulker Profile

To achieve the same strength as steel, alloy toe caps often need to be slightly thicker. This can result in a slightly more "bulbous" or prominent toe box compared to some modern steel or composite designs.

Market Availability

While growing in popularity, alloy toe shoes can still be less common on the market compared to the vast selection of steel and composite toe options available.

Making the Right Choice for Your Needs

Selecting the right material combination depends entirely on your daily tasks, environment, and comfort priorities.

- If your primary focus is all-day comfort and reduced fatigue: An alloy toe is an ideal choice, especially in an athletic-style shoe with synthetic and mesh uppers.

- If your primary focus is a professional appearance: Look for business-casual styles that pair an alloy toe with a durable leather or suede upper.

- If your primary focus is maximum durability in a lighter boot: A traditional work boot made with full-grain leather and an alloy toe provides an excellent balance of toughness and comfort.

Ultimately, understanding the materials allows you to choose a safety shoe that protects you without compromising on comfort or function.

Summary Table:

| Material Type | Common Examples | Key Characteristics |

|---|---|---|

| Toe Cap (Alloy) | Aluminum, Titanium | Lightweight, ASTM F2413-18 certified protection |

| Upper (Leather) | Full-grain, Suede, Nubuck | Durable, professional style, abrasion-resistant |

| Upper (Synthetics) | Mesh, Textiles | Lightweight, breathable, flexible, athletic feel |

| Upper (Casual) | Canvas, Cloth, Linen | Comfortable, breathable, ideal for light-duty work |

Ready to source high-quality alloy toe shoes?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work shoes and boots, ensuring you get the perfect combination of protection, comfort, and style.

Contact our team today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What features make oilfield safety shoes resistant to heat and flames? Protect Against Extreme Temperatures

- What chemical protection features do safety shoes offer? A Guide to Hazard-Resistant Footwear

- What broader role do safety shoes play in workplace safety culture? Building a Foundation of Trust and Accountability

- How does the structural design of safety shoes affect ATV control? Enhance Braking Power & Operational Efficiency

- Why must the Clo value of safety footwear be included in perceived temperature assessments for road workers?

- What is the lightest type of safety-toe boot available? The Ultimate Guide to Alloy Toes

- What are the historical origins of composite-toe boots? From Wooden Clogs to Modern Safety

- What role do slip-resistant rubber materials play in safety shoes? Ensuring Grip and Stability in Hazardous Workplaces