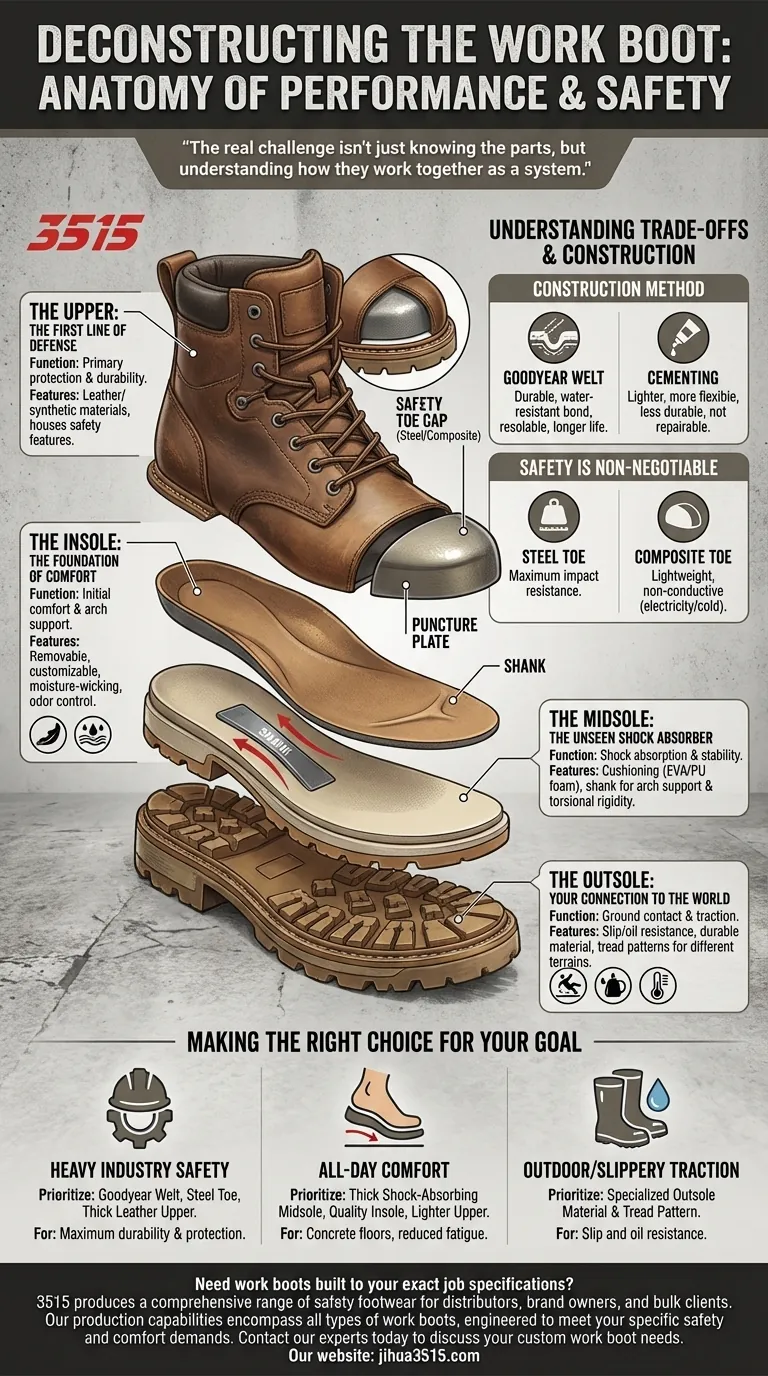

In essence, a work boot is a system of four critical parts: the upper, which protects the top of your foot; the insole, which provides initial comfort; the midsole, which absorbs shock and adds stability; and the outsole, which grips the ground. These core components are then enhanced with specific materials and features designed for safety and durability in demanding environments.

The real challenge isn't just knowing the parts of a work boot, but understanding how they work together as a system to deliver the specific protection, support, and durability your job requires.

Deconstructing the Work Boot: From the Ground Up

A work boot is far more than just a heavy-duty shoe. Each component is engineered to serve a specific function, and their combined quality determines the boot's overall performance and lifespan. Let's break down each layer.

The Outsole: Your Connection to the World

The outsole is the part of the boot that makes direct contact with the ground. Its design is one of the most critical factors for safety and performance.

The material and tread pattern determine its resistance to slips, oil, heat, and abrasion. A heavy-lugged pattern provides excellent traction on uneven, natural terrain, while a flatter design might be better for smooth, indoor surfaces.

The Midsole: The Unseen Shock Absorber

Sandwiched between the outsole and the insole, the midsole's primary job is to provide cushioning, absorb impact, and offer stability.

This layer is often made from materials like EVA foam or polyurethane. The midsole can also house a shank—a rigid piece of steel or composite material—that adds crucial arch support and torsional rigidity, preventing the boot from twisting under load.

The Insole: The Foundation of Comfort

The insole is the removable layer your foot rests on directly. It provides the initial feeling of comfort and arch support.

While factory insoles offer basic cushioning, many professionals replace them with specialized versions for better arch support, moisture-wicking properties, or odor control. This is the most easily customized part of the boot.

The Upper: The First Line of Defense

The upper is everything that covers the top and sides of your foot. It's responsible for protection, durability, and environmental resistance.

Traditionally made from thick leather like cowhide for its durability, uppers now also use advanced synthetic fabrics for lighter weight and breathability. This is also where you'll find safety features like steel or composite toe caps.

Understanding the Trade-offs and Construction

The way these parts are assembled is just as important as the parts themselves. The construction method dictates the boot's durability, flexibility, and repairability.

The Importance of Stitching and Welt

High-quality construction methods, like a Goodyear welt, involve stitching the upper to the outsole. This creates an incredibly durable and water-resistant bond that also allows the boot to be resoled, extending its life significantly.

Less expensive methods may involve cementing (gluing) the sole, which is lighter and more flexible but far less durable and generally not repairable.

Safety is Non-Negotiable

The single most critical aspect of any work boot is its ability to protect you from job-site hazards. A boot's safety features are not optional accessories; they are essential equipment.

Choosing between a steel toe for maximum impact resistance or a lighter composite toe that doesn't conduct electricity or cold depends entirely on the specific risks present in your work environment. Some boots also include a puncture plate in the sole to protect against sharp objects from below.

Making the Right Choice for Your Goal

Selecting a work boot requires matching its components and construction to your specific daily tasks and work environment.

- If your primary focus is safety in heavy industry: Prioritize a Goodyear welt construction with a steel toe and a thick leather upper for maximum durability and protection.

- If your primary focus is all-day comfort on concrete floors: Look for a boot with a thick, shock-absorbing midsole, a quality supportive insole, and a lighter-weight upper.

- If your primary focus is traction in outdoor or slippery conditions: Scrutinize the outsole's material and tread pattern to ensure it is rated for slip and oil resistance.

Ultimately, the right work boot is the one whose every part is engineered to solve the specific challenges you face every day.

Summary Table:

| Part | Function | Key Features |

|---|---|---|

| Outsole | Ground contact & traction | Slip/oil resistance, lug patterns |

| Midsole | Shock absorption & stability | Cushioning (EVA/PU), shank for arch support |

| Insole | Foundation for comfort | Removable, customizable for support |

| Upper | Primary protection & durability | Leather/synthetics, houses safety toe |

Need work boots built to your exact job specifications?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes, engineered with the precise combination of parts—from durable uppers to specialized outsoles—to meet your specific safety and comfort demands.

Contact our experts today to discuss your custom work boot needs and benefit from our manufacturing expertise.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What are the key considerations when choosing safety boots? Match Hazards to Features for Maximum Protection

- What boots do they wear on oil rigs? Essential Safety Footwear for Harsh Conditions

- How does routine boot maintenance benefit workplace safety? Proactive PPE Protection for Your Workforce

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection

- What is the primary purpose of safety shoes? Your Ultimate Guide to Workplace Foot Protection