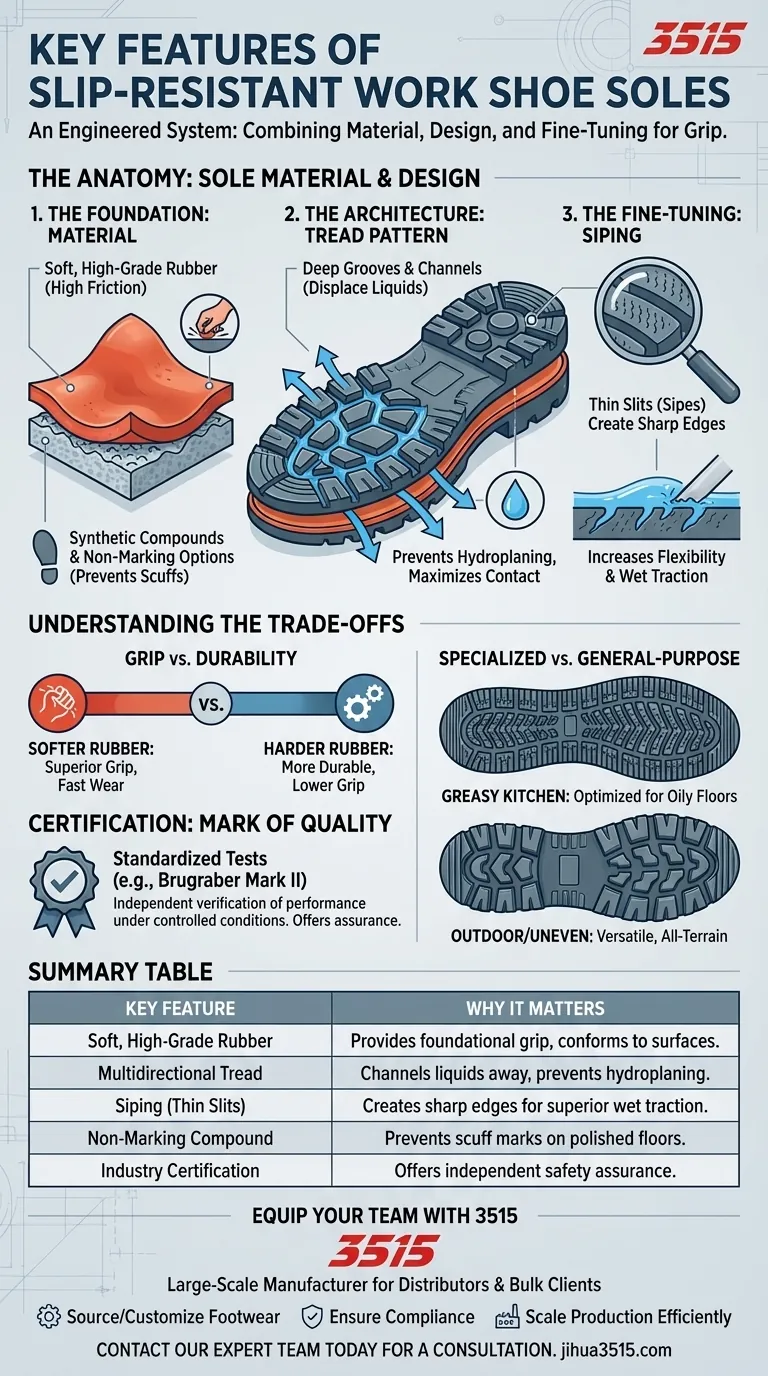

To understand the sole of a slip-resistant shoe, you must look at its material and its design. The most effective soles are made from a soft, high-grade rubber compound and feature a complex tread pattern with deep, multidirectional grooves and thin slits (sipes) designed to channel liquids away and maximize surface contact.

The core principle of a slip-resistant sole is not a single feature, but an engineered system. It combines a high-friction material with a specific tread architecture that actively clears liquids from beneath the foot to maintain a secure grip.

The Anatomy of a Slip-Resistant Sole

A shoe's ability to prevent slips is determined almost entirely by the design and composition of its outsole. Understanding these elements is key to making an informed choice.

The Foundation: Sole Material

The material itself is the first line of defense. A compound that creates high friction is essential for gripping smooth or wet surfaces.

Most high-quality slip-resistant soles are made of soft, high-grade rubber. This material naturally offers excellent grip, conforming slightly to microscopic imperfections in the floor.

Some soles use specialized synthetic compounds engineered for specific environments. A key feature to look for is a "non-marking" sole, which prevents leaving scuff marks on polished floors.

The Architecture: Tread Pattern Design

The pattern of the sole is not for aesthetics; it is a functional system for fluid dynamics. A flat sole would simply hydroplane on a wet surface.

Effective tread patterns, often using hexagonal or circular shapes, create channels. These channels are designed to direct water, oil, and other liquids out from under the shoe.

The depth of the grooves is also critical. Deeper grooves can displace a greater volume of liquid, ensuring the solid parts of the tread make direct contact with the floor.

The Fine-Tuning: Siping for Wet Surfaces

For maximum performance on wet or oily surfaces, look for siping. Sipes are very thin slits or cuts made across the rubber tread blocks.

These tiny channels increase the sole's flexibility and create thousands of extra sharp edges. This dramatically improves traction by cutting through the thin film of liquid that causes hydroplaning.

Understanding the Trade-offs

No single shoe is perfect for every situation. Choosing the right one involves balancing competing factors.

Grip vs. Durability

There is often a direct trade-off between the softness of the rubber and its longevity.

A softer rubber compound provides superior grip because it has a higher coefficient of friction. However, this same softness means it will wear down more quickly with regular use.

A harder, more durable compound will last longer but may offer slightly less traction, especially on very smooth surfaces.

Specialized vs. General-Purpose Treads

A tread pattern optimized for a greasy kitchen floor (small, intricate channels) may not be ideal for loose gravel or uneven outdoor terrain.

Consider your primary work environment. A highly specialized sole offers the best protection for its intended hazard but may be less effective as an all-purpose shoe.

Certification as a Mark of Quality

The term "slip-resistant" is not always regulated. Look for shoes that specify they have passed standardized tests, such as the Brugraber Mark II Test or other industry certifications.

This independent verification provides a level of assurance that the shoe performs as advertised under controlled laboratory conditions.

Making the Right Choice for Your Goal

Select a shoe based on the specific hazards you face every day.

- If your primary focus is working on consistently wet or oily floors: Prioritize soles with deep, liquid-channeling treads and prominent siping.

- If your primary focus is durability and all-day comfort: Look for a quality rubber sole combined with strong stitching, good arch support, and a padded collar.

- If your primary focus is moving between varied indoor and outdoor surfaces: Choose a durable sole with a versatile, multidirectional tread pattern that can handle both smooth floors and uneven ground.

- If your primary focus is protecting finished floors: Ensure the sole is explicitly labeled as "non-marking" to prevent scuffs and black marks.

Ultimately, the right work shoe is a critical piece of safety equipment designed to keep you stable and secure in your specific environment.

Summary Table:

| Key Feature | What It Does | Why It Matters |

|---|---|---|

| Soft, High-Grade Rubber | Creates high friction and conforms to floor surfaces. | Provides the foundational grip to prevent slips. |

| Multidirectional Tread Pattern | Channels water, oil, and liquids away from the foot. | Prevents hydroplaning on wet or greasy floors. |

| Siping (Thin Slits) | Increases flexibility and creates thousands of sharp edges. | Cuts through thin liquid films for superior wet traction. |

| Non-Marking Compound | Prevents scuff marks on polished floors. | Protects your workspace while maintaining safety. |

| Industry Certification (e.g., Mark II) | Verifies performance against standardized slip tests. | Offers independent assurance of the shoe's safety claims. |

Ready to Equip Your Team with Superior Slip-Resistant Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance work shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, engineered with the precise sole compounds and tread designs detailed above to protect your workforce.

We can help you:

- Source or Customize footwear tailored to your specific workplace hazards.

- Ensure Compliance with industry safety standards.

- Scale Production efficiently to meet your volume needs.

Let's discuss your requirements and build a safer solution together.

Contact our expert team today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear