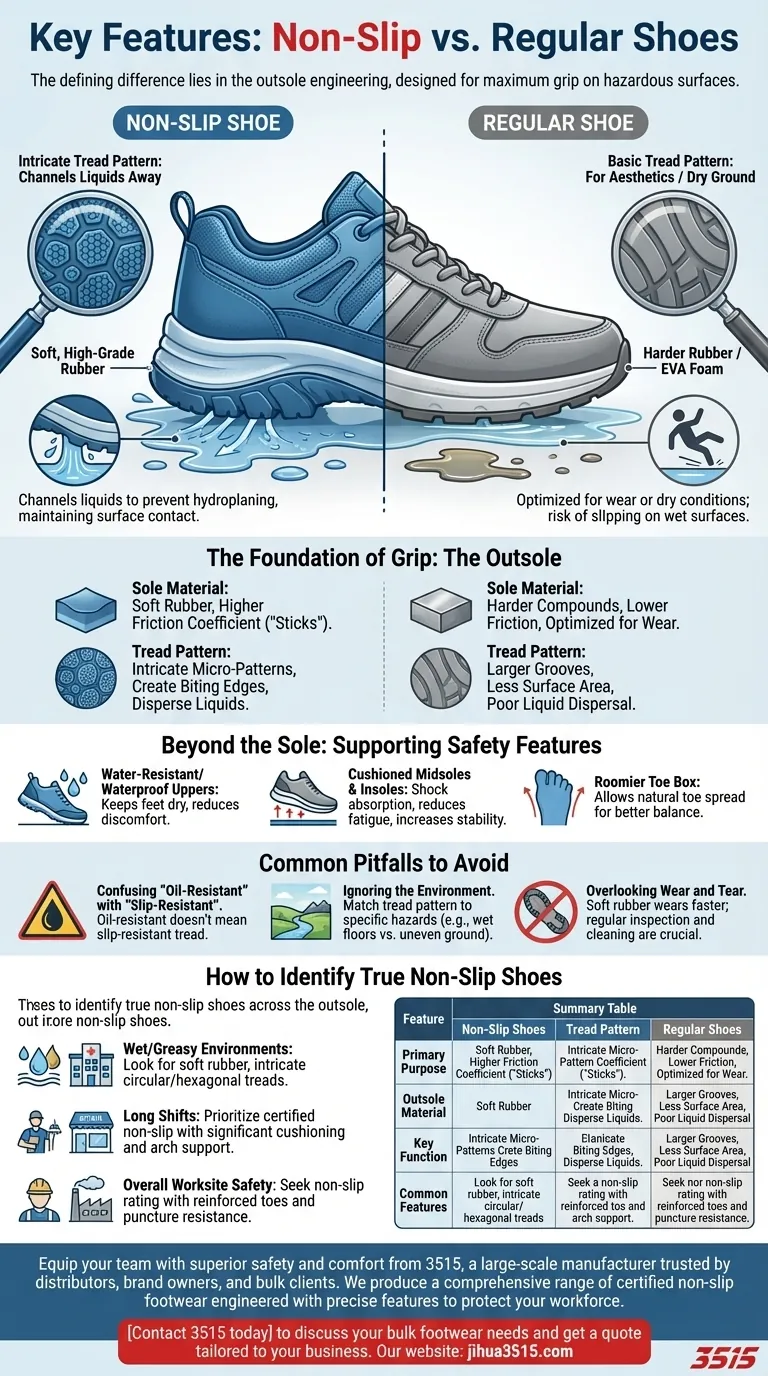

The defining difference between non-slip and regular shoes lies entirely in the engineering of the outsole. While they may look similar on the surface, non-slip shoes are purpose-built with specific materials and tread patterns designed to create maximum friction and maintain grip on wet, oily, or otherwise slick surfaces. Regular shoes are simply not designed for these hazardous conditions.

The core principle of a non-slip shoe is a two-part system: a soft rubber outsole that grips the floor, combined with an intricate tread pattern that actively channels liquids away. This design ensures the sole maintains direct contact with the surface, preventing the hydroplaning effect that causes slips.

The Foundation of Grip: The Outsole

The outsole—the part of the shoe that touches the ground—is where all the critical safety engineering happens. It’s a combination of material science and fluid dynamics.

Sole Material: The Point of Contact

Regular shoes often use harder, more durable compounds like carbon rubber or EVA foam for their soles, which are optimized for wear resistance or cushioning on dry surfaces.

Non-slip shoes, however, almost exclusively use high-grade, soft rubber or synthetic rubber. This material has a higher coefficient of friction, meaning it naturally "sticks" to surfaces more effectively, providing a foundational layer of grip.

Tread Pattern: The Engineering of Traction

The tread pattern on a regular shoe is often designed for aesthetics or for traction on solid ground.

A non-slip shoe features a very different design. The tread consists of intricate, often hexagonal or circular micro-patterns. These small, tightly-spaced grooves create more surface area and biting edges to grip the floor. More importantly, they act as channels to disperse water, grease, and other liquids away from the bottom of the shoe.

This channeling action is critical. By quickly moving liquid out from under the sole, the shoe prevents a thin layer of fluid from forming, which is what causes a person to hydroplane and slip.

Beyond the Sole: Supporting Safety Features

While the outsole is the primary differentiator, other features contribute to the overall safety and performance of non-slip shoes, especially in a professional setting.

Upper Material and Construction

Many non-slip shoes feature water-resistant or waterproof uppers. This keeps the wearer's feet dry and comfortable, which is crucial in environments where spills are common. Dry feet also reduce the risk of blisters and discomfort over long shifts.

Midsole and Insole Design

To combat fatigue from standing for hours, quality non-slip shoes often include thick, shock-absorbing midsoles and cushioned insoles. By reducing strain on the feet, legs, and back, these features help the wearer stay more alert and stable, indirectly contributing to safety.

Overall Fit and Structure

You will often find that non-slip work shoes have a roomier toe box. This allows the toes to spread out naturally, improving balance and stability throughout a long day of standing and moving.

Common Pitfalls to Avoid

Choosing the right shoe involves understanding its intended purpose and limitations. Not all "non-slip" labels are equal.

Confusing "Oil-Resistant" with "Slip-Resistant"

An "oil-resistant" sole means the rubber material won't degrade when exposed to petroleum products. It does not automatically mean the shoe has a slip-resistant tread design. True non-slip shoes are both oil- and slip-resistant.

Ignoring the Environment

A shoe designed for a wet hospital floor may not have the deep, rugged lugs needed for uneven or loose surfaces at a construction site. The tread pattern should match the specific hazard you face most often.

Overlooking Wear and Tear

The soft rubber that makes non-slip shoes so effective also tends to wear down more quickly than the harder rubber on regular shoes. The intricate tread patterns can also get clogged with debris. Regular inspection and cleaning are necessary to ensure they remain effective.

How to Identify True Non-Slip Shoes

Focus on the specific features that match your work environment to ensure you get the protection you need.

- If your primary focus is working in wet or greasy environments (e.g., kitchens, hospitals): Look for soft rubber soles with small, intricate, and circular tread patterns designed to channel away liquids.

- If your primary focus is standing for long shifts (e.g., retail, food service): Prioritize shoes that combine a certified non-slip outsole with significant midsole cushioning and arch support.

- If your primary focus is overall worksite safety (e.g., manufacturing, logistics): Seek shoes that are rated non-slip but also include features like reinforced safety toes and puncture-resistant soles.

Ultimately, understanding that a shoe's grip is an engineered system of material and design is the key to making an informed choice for your safety.

Summary Table:

| Feature | Non-Slip Shoes | Regular Shoes |

|---|---|---|

| Primary Purpose | Slip prevention on wet/greasy surfaces | General use, aesthetics, comfort |

| Outsole Material | High-grade, soft rubber | Harder rubber or EVA foam |

| Tread Pattern | Intricate micro-patterns (hexagons/circles) | Larger, less dense patterns |

| Key Function | Channels liquids away to prevent hydroplaning | Provides basic traction on dry ground |

| Common Features | Water-resistant uppers, cushioned midsoles | Varies widely by style |

Equip your team with superior safety and comfort from 3515, a large-scale manufacturer trusted by distributors, brand owners, and bulk clients.

We produce a comprehensive range of certified non-slip footwear engineered with the precise features outlined above—soft rubber outsoles, effective tread patterns, and supportive designs—to protect your workforce in kitchens, hospitals, factories, and more. Our production capabilities encompass all types of safety shoes and boots, ensuring durability and performance.

Contact 3515 today to discuss your bulk footwear needs and get a quote tailored to your business.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What are non-slip shoes? Essential Safety Footwear for High-Risk Workplaces

- How does outsole traction contribute to workplace safety? Slip-Resistant Footwear Engineering

- What is the technical purpose of requiring full-coverage work shoes in food factories or catering kitchens? Ensure Safety & Hygiene Standards

- How can the lifespan and effectiveness of slip-resistant work shoes be maximized? Proactive Maintenance for Ultimate Safety

- What special requirements should work shoes for all-day wear meet? Key Features for All-Day Comfort & Safety

- What additional safety features might be required in slip-resistant work shoes? Essential Protection for Your Workplace

- How does the comfort of specialized work shoes influence biosecurity compliance? Drive Adherence in Agriculture

- What is the primary role of industrial-grade 3D printing in shoe last & insole research? Enhance Your Slip-Resistance