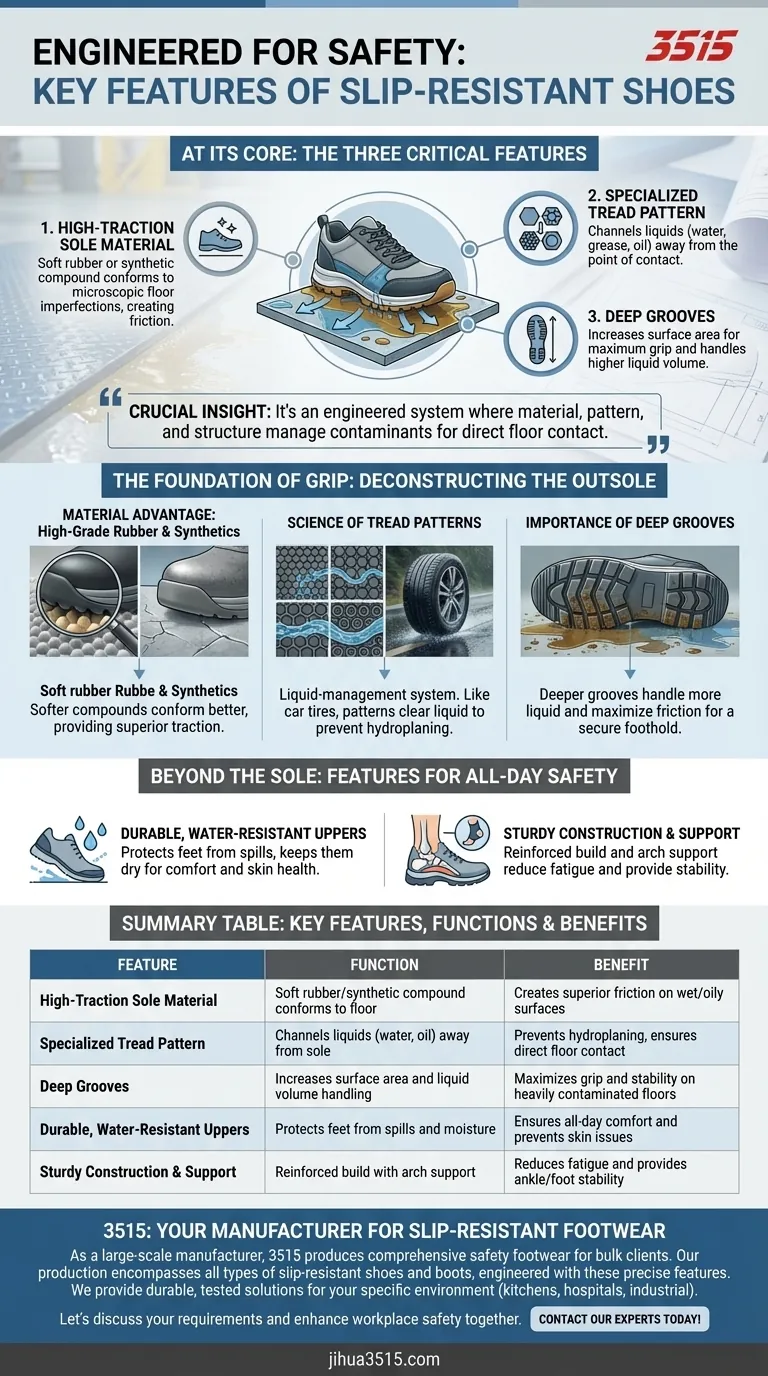

At its core, a slip-resistant shoe is defined by three critical features: a high-traction sole made from soft rubber or a synthetic compound, a specialized tread pattern designed to channel liquids away from the point of contact, and deep grooves that increase the surface area for maximum grip. These elements work together to provide stability on wet, oily, or otherwise slick surfaces.

The crucial insight is that slip-resistant shoes are not merely about having a "grippy" bottom. They are an engineered system where the sole's material, pattern, and structure actively manage contaminants to maintain direct contact with the floor.

The Foundation of Grip: Deconstructing the Outsole

The vast majority of a shoe's slip resistance comes from the design and composition of its outsole—the part that directly touches the ground. Understanding these components is key to identifying effective footwear.

The Material Advantage: High-Grade Rubber and Synthetics

The material of the sole is the first line of defense. Softer compounds like high-grade rubber or polyurethane provide superior traction because they can conform better to microscopic imperfections in a floor surface.

This creates more friction than the harder, less pliable materials found in standard footwear.

The Science of Tread Patterns

The pattern on the bottom of the shoe is not for aesthetics; it's a functional liquid-management system.

Effective slip-resistant shoes often use interlocking tread patterns, such as small hexagons or circles. These shapes create channels that efficiently push water, grease, and oil out from under the sole.

Think of it like the treads on a car tire in the rain. By clearing the liquid, the pattern ensures the sole makes solid contact with the floor itself, dramatically reducing the risk of hydroplaning.

The Importance of Deep Grooves

In addition to the overall pattern, the depth of the grooves is critical. Deeper channels can handle a higher volume of liquid and increase the overall surface area of the sole.

This enhanced surface area maximizes the friction between the shoe and the floor, providing a more secure foothold even on heavily contaminated surfaces.

Beyond the Sole: Features for All-Day Safety

While the outsole is the star player, other features contribute to the overall safety, durability, and comfort required in hazardous work environments.

Durable, Water-Resistant Uppers

The material on the top of the shoe, known as the upper, should be durable and water-resistant. This protects your feet from spills and keeps them dry, which is essential for comfort and preventing skin issues during long shifts.

Sturdy Construction and Support

Slip-resistant shoes are built to withstand demanding professions. Look for sturdy, reinforced construction and adequate arch support.

This ensures the shoe provides stability for your entire foot and ankle, reducing fatigue and preventing injuries that can occur from a loss of balance, even if a slip doesn't happen.

Understanding the Trade-offs and Verifying Claims

Not all shoes marketed as "slip-resistant" are created equal. Being an informed buyer means recognizing the difference between marketing language and proven performance.

Not All Labels Are Equal

The most reliable feature is an explicit slip-resistant label that indicates the shoe has passed standardized industry tests for traction.

A simple claim on a box is less reliable than a shoe that specifies it meets certain safety standards. Always prioritize footwear that has been formally tested and certified.

The Balance Between Grip and Wear

Extremely soft rubber compounds offer phenomenal grip but may wear down faster than harder materials. Manufacturers are constantly balancing maximum traction with long-term durability.

Be aware that the effectiveness of any slip-resistant shoe will diminish as the tread wears down over time.

Consider Your Specific Environment

The ideal slip-resistant shoe for a greasy commercial kitchen may have a different sole composition than one designed for the wet floors of a hospital. Consider the specific hazards you face daily when making a choice.

Making the Right Choice for Your Workplace

Use your primary work hazard to guide your decision on which features to prioritize.

- If your primary focus is working on water-slicked floors: Prioritize shoes with aggressive, open-ended tread patterns and deep grooves to channel water away quickly.

- If your primary focus is navigating oily and greasy surfaces: Prioritize shoes with a high-grade rubber sole specifically rated for oil resistance, as some materials degrade with oil contact.

- If your primary focus is all-day comfort and support: Ensure that beyond the slip-resistant outsole, the shoe offers excellent arch support and sturdy construction to reduce fatigue.

Ultimately, a true slip-resistant shoe is an essential piece of personal protective equipment, engineered to keep you safe from the ground up.

Summary Table:

| Key Feature | Function | Benefit |

|---|---|---|

| High-Traction Sole Material | Soft rubber/synthetic compound conforms to floor | Creates superior friction on wet/oily surfaces |

| Specialized Tread Pattern | Channels liquids (water, oil) away from sole | Prevents hydroplaning, ensures direct floor contact |

| Deep Grooves | Increases surface area and liquid volume handling | Maximizes grip and stability on heavily contaminated floors |

| Durable, Water-Resistant Uppers | Protects feet from spills and moisture | Ensures all-day comfort and prevents skin issues |

| Sturdy Construction & Support | Reinforced build with arch support | Reduces fatigue and provides ankle/foot stability |

Need reliable, high-quality slip-resistant footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the precise features outlined above to protect your workforce.

We can provide durable, tested solutions tailored to your specific environment—whether it's a greasy kitchen, a wet hospital floor, or an industrial setting.

Let's discuss your requirements and how we can enhance workplace safety together. Contact our experts today for a consultation!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How does the structural design of industrial-grade safety shoes provide protection? Engineering Foot Health at Work

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety