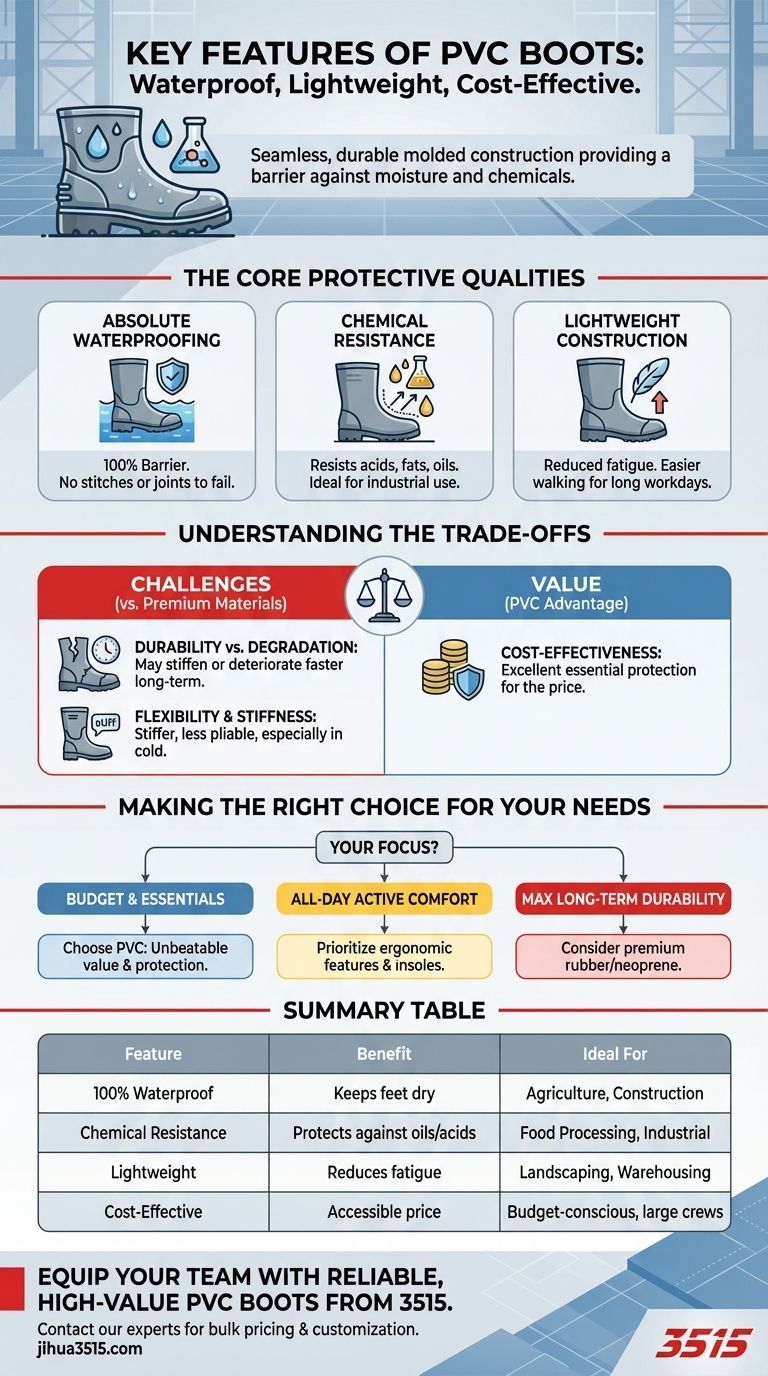

At their core, PVC boots are defined by their complete waterproof protection, lightweight construction, and significant cost-effectiveness. Made from polyvinyl chloride, they are manufactured using a molding process that creates a seamless, durable barrier against moisture and a wide range of chemicals, making them a practical choice for numerous work and wet-weather environments.

The essential value of PVC boots lies in their balance: they provide a high degree of elemental and chemical protection at a very accessible price point, though this comes with trade-offs in long-term durability and flexibility compared to premium materials.

The Core Protective Qualities of PVC

The primary function of any utility boot is protection, and PVC excels in several key areas. Its material properties and construction method give it distinct advantages.

Absolute Waterproofing

The manufacturing process for PVC boots involves injecting heated liquid PVC into a boot-shaped mold. As it cools, it forms a single, seamless piece with no stitches or joints that could fail.

This construction method ensures the boots are 100% waterproof, providing a reliable barrier that keeps feet completely dry in wet, muddy, or flooded conditions.

Resistance to Chemicals and Substances

Polyvinyl chloride is inherently resistant to many acids, fats, oils, and other common chemicals. This makes PVC boots a standard choice in agriculture, food processing, and industrial settings where exposure is a daily reality.

The level of resistance can vary by the specific PVC compound, but their general performance offers a strong layer of safety.

Lightweight Construction

Compared to traditional materials like heavy-duty rubber, PVC is significantly lighter. This reduction in weight directly translates to reduced foot and leg fatigue over a long workday.

Being lighter makes them easier to walk in and suitable for jobs that require being on your feet all day.

Understanding the Trade-offs

While PVC offers excellent value, it's critical to understand its limitations to make an informed decision. These trade-offs are what separate PVC from more expensive alternatives like specialized rubber or neoprene.

Durability vs. Material Degradation

PVC boots offer good durability for their cost. However, the material is generally less resilient than premium rubber over the long term.

Over time and with heavy use, PVC can become stiff, lose its original shape, or even deteriorate faster. This makes them less of a long-term investment compared to boots made from more robust materials.

Flexibility and Stiffness

One of the most noticeable differences between PVC and rubber is flexibility. PVC boots are typically stiffer and less pliable.

While modern designs incorporate features to improve comfort, this inherent stiffness can be a factor for tasks requiring constant kneeling or bending.

Making the Right Choice for Your Needs

Choosing the right boot depends entirely on balancing your budget against your performance requirements.

- If your primary focus is budget and essential protection: PVC offers an unbeatable combination of waterproofing, chemical resistance, and affordability.

- If your primary focus is all-day comfort in active roles: Be aware of PVC's inherent stiffness and prioritize models with features like cushioned insoles and ergonomic designs.

- If your primary focus is maximum long-term durability for heavy use: Acknowledge that while PVC is tough, premium rubber or neoprene boots may offer a longer service life.

Ultimately, PVC boots provide exceptional and reliable protection for their cost, making them an intelligent choice for a wide range of applications.

Summary Table:

| Key Feature | Benefit | Ideal For |

|---|---|---|

| 100% Waterproof | Keeps feet dry in wet/muddy conditions | Agriculture, Construction, Fishing |

| Chemical Resistance | Protects against oils, acids, and fats | Food Processing, Industrial Cleaning |

| Lightweight | Reduces foot fatigue for all-day wear | Landscaping, Warehousing |

| Cost-Effective | Provides essential protection at an accessible price | Budget-conscious buyers, large crews |

Equip your team with reliable, high-value PVC boots from 3515.

As a large-scale manufacturer, we produce a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and utility boots, ensuring you get the right protection for your specific needs at a competitive price.

Contact our experts today for bulk pricing, customization options, and to discuss your requirements.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the best shoes for walking in the rain? Stay Dry & Safe with the Right Gear

- How are PVC rain boots packaged for shipment? Bulk vs. Custom Branding

- How should wellington boots be maintained to ensure longevity? Prevent Cracks & Extend Boot Life

- What are the best wellies for individuals with wide calves? Find Your Perfect, Comfortable Fit

- What should you consider when choosing shoes for wet weather? Key Features for Dry, Safe Feet

- What should be considered when selecting wellington boots for dog walking? Find Your Perfect Fit for All-Weather Walks

- Who developed Wellington boots and what was their original purpose? From Military Necessity to Modern Icon

- What are the advantages of neoprene-lined wellingtons? Superior Warmth, Comfort & Fit