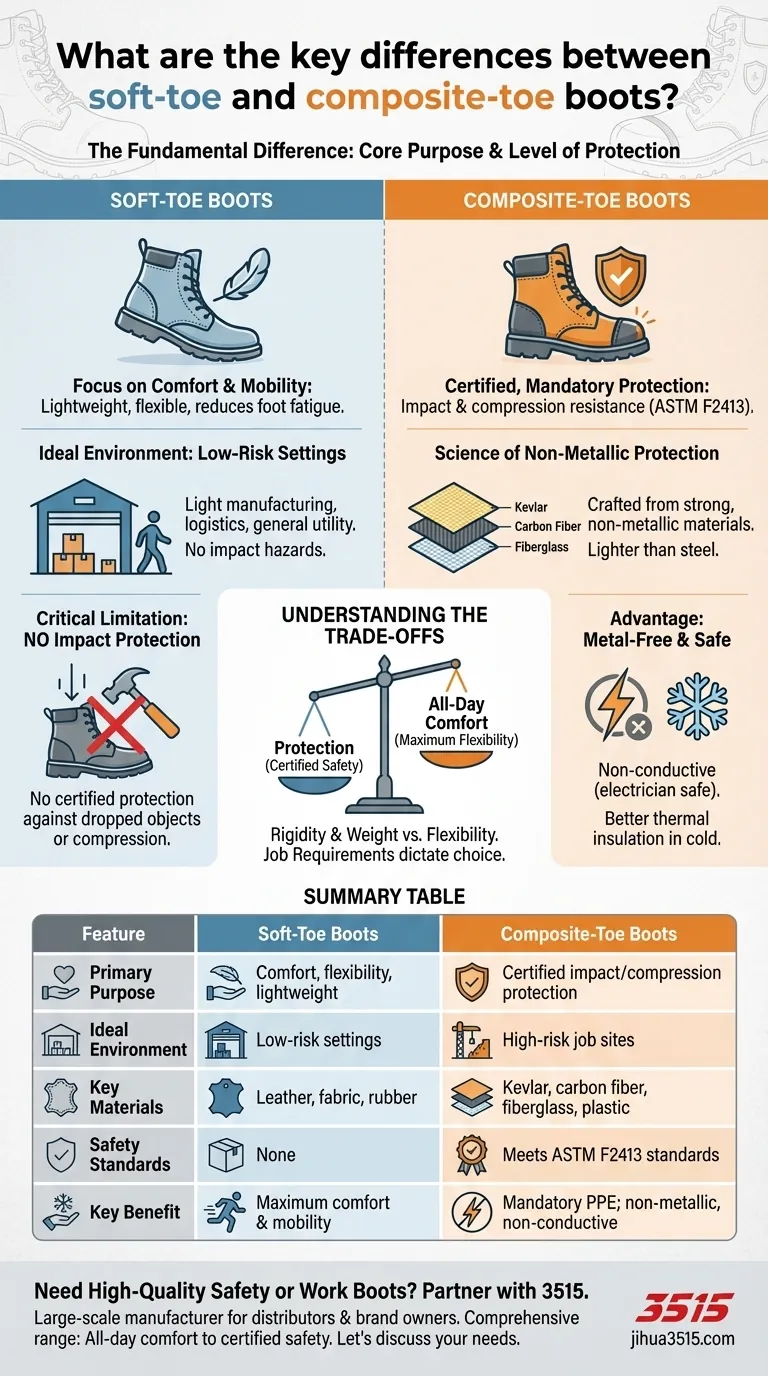

The fundamental difference between soft-toe and composite-toe boots lies in their core purpose and level of protection. Soft-toe boots are designed for lightweight comfort and flexibility in low-risk work environments. Composite-toe boots are engineered with non-metallic materials like carbon fiber or Kevlar to provide certified, mandatory protection against impact and compression in hazardous job sites.

The choice is not about which boot is "better," but which is correct for your environment. Soft-toe boots are for mobility where danger is minimal, whereas composite-toe boots are a non-negotiable piece of personal protective equipment (PPE) for jobs with impact risks.

A Closer Look at Soft-Toe Boots

The Focus on Comfort and Mobility

Soft-toe boots are significantly lighter and more flexible than any safety-toe counterpart.

This reduction in weight translates directly to less foot fatigue over a long workday, making them ideal for roles that require constant walking or standing.

The Ideal Work Environment

These boots are designed for professions where the primary risks are not from falling objects, rolling equipment, or heavy machinery.

Think of roles in light manufacturing, logistics, or general utility work where agility and comfort are paramount and impact hazards are absent.

The Critical Limitation: No Impact Protection

It is crucial to understand that soft-toe boots offer no certified protection against impact or compression.

While they provide basic coverage for your feet, they will not prevent a serious injury from a dropped tool or heavy object.

Understanding Composite-Toe Technology

The Science of Non-Metallic Protection

Composite safety toes are crafted from a blend of strong, non-metallic materials.

These advanced materials can include Kevlar, carbon fiber, fiberglass, and other durable plastics to create a protective cap.

Built to Meet Safety Standards

Unlike soft-toe boots, composite-toe models are designed and tested to meet or exceed industry safety standards (such as ASTM F2413) for impact and compression resistance.

This makes them essential protective equipment in high-risk environments like construction, industrial settings, and manufacturing facilities.

The Advantage of Being Metal-Free

A key benefit of composite materials is that they do not conduct electricity, making them a safer choice for electricians and similar trades.

They are also lighter than steel-toe caps and do not transfer cold as readily in low-temperature environments.

Understanding the Trade-offs

Protection vs. All-Day Comfort

The primary trade-off is certified safety versus maximum flexibility. The protective cap in a composite boot adds rigidity and some weight compared to a completely unstructured soft-toe.

While composite toes are lighter than steel, they are inherently heavier and less flexible than a boot with no protective cap at all.

Job Requirement vs. Personal Preference

For many workers, the decision is made for them by workplace safety regulations.

If your job site mandates safety-toe footwear, a soft-toe boot is simply not an option, regardless of its comfort advantages. The risk of injury and non-compliance is too high.

Making the Right Choice for Your Job

Your work environment and its specific hazards should always be the deciding factor in your choice of footwear.

- If your primary focus is all-day comfort in a low-risk setting: A soft-toe boot provides the best combination of light weight and flexibility.

- If your primary focus is mandatory impact protection: A composite-toe boot is the necessary standard for safety compliance on most job sites.

- If you need a safety toe but want to minimize weight and avoid metal: A composite-toe boot offers the ideal modern alternative to a traditional steel-toe.

Choosing the right boot is a foundational element of your daily safety and performance on the job.

Summary Table:

| Feature | Soft-Toe Boots | Composite-Toe Boots |

|---|---|---|

| Primary Purpose | Comfort, flexibility, lightweight | Certified impact/compression protection |

| Ideal Environment | Low-risk settings (e.g., logistics, light manufacturing) | High-risk job sites (e.g., construction, industrial) |

| Key Materials | Leather, fabric, rubber | Kevlar, carbon fiber, fiberglass, plastic |

| Safety Standards | None | Meets ASTM F2413 standards |

| Key Benefit | Maximum comfort and mobility | Mandatory PPE; non-metallic, non-conductive |

Need High-Quality Safety or Work Boots? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether your customers need the all-day comfort of soft-toe boots or the certified safety of composite-toe boots, our production capabilities encompass all types of shoes and boots to meet your exact specifications.

Let's discuss your needs: Contact our team today to explore our catalog and manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards