At its core, the traditional engineer boot is a masterclass in purpose-driven design. Its key features include a tall, laceless leather shaft, an adjustable buckle and strap over the instep, a second buckle at the top of the shaft, a plain round toe, and a rugged, welted sole construction. This minimalist silhouette was born from the functional needs of industrial workers in the early 20th century.

Every element of the engineer boot was conceived for a single purpose: to provide maximum protection and durability for workers in hazardous environments. Understanding this functional origin is the key to appreciating its timeless design and inherent trade-offs.

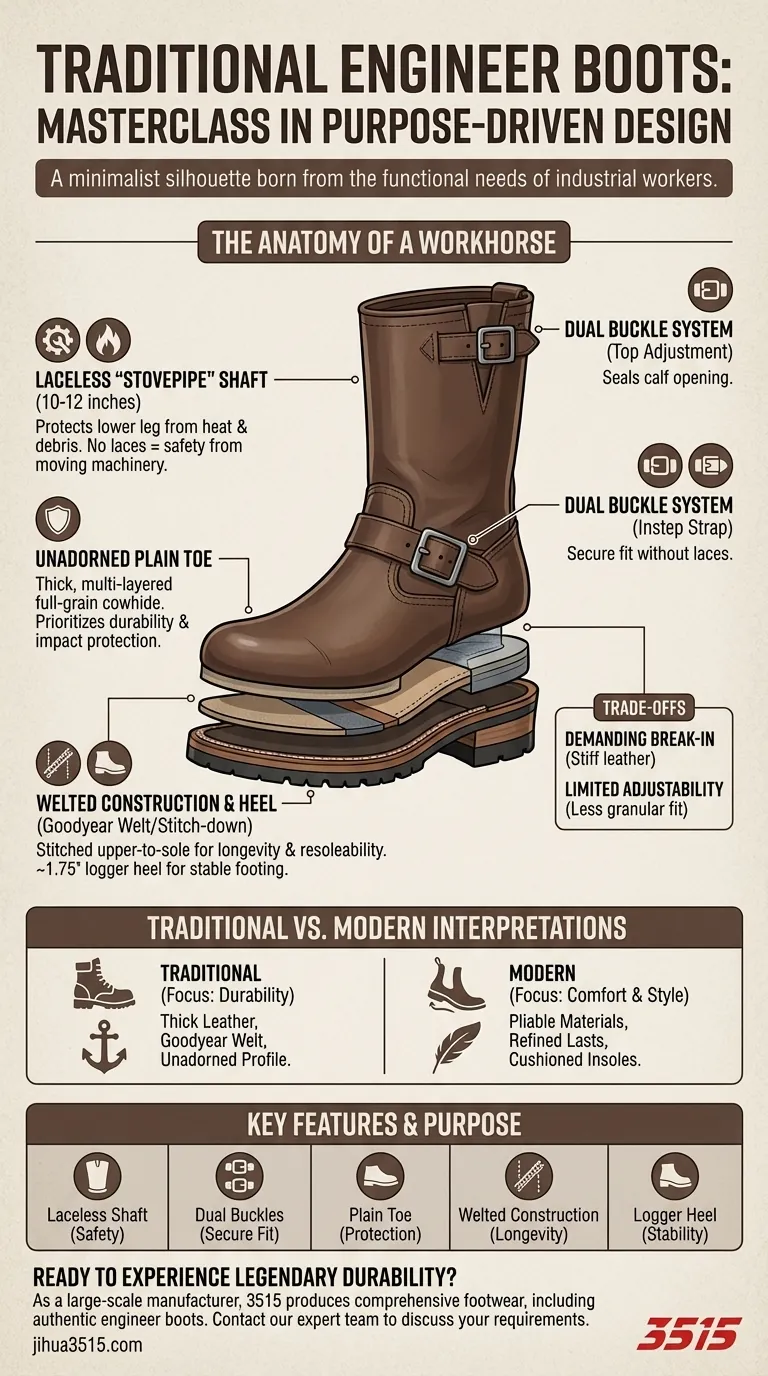

The Anatomy of a Workhorse: Deconstructing the Design

The engineer boot's iconic look is not the result of styling, but of pure function. Each component was engineered to solve a specific problem faced by steam locomotive firemen, welders, and other heavy laborers.

The Laceless "Stovepipe" Shaft

The most recognizable feature is the tall shaft, typically 10 to 12 inches high, with no laces. This "stovepipe" design was critical for protecting the wearer's lower legs from hot embers, sparks, and debris.

The complete absence of laces is a crucial safety feature. It eliminates the risk of laces getting caught in moving machinery, a significant danger in early industrial settings.

The Dual Buckle System

To provide a secure fit without laces, engineer boots rely on two adjustable buckle and strap systems.

The primary buckle is located over the instep, allowing the wearer to tighten the boot securely around the foot. A second buckle at the top of the shaft allows for adjustment around the calf, sealing the opening.

The Unadorned Plain Toe

Unlike more decorative footwear, the traditional engineer boot features a simple, rounded plain toe. This design prioritizes durability and protection.

The toe box is constructed from thick, often multi-layered, full-grain cowhide to shield the foot from impacts. The lack of stitching or perforations (like a "brogue" or "cap-toe") creates fewer points of failure.

The Foundation: Construction and Heel

High-quality engineer boots are built for longevity using traditional methods like Goodyear welt or stitch-down construction. These techniques stitch the upper to the sole, making the boots exceptionally durable and fully resoleable.

The sole itself is thick leather or hard-wearing rubber. The heel is typically 1.75 inches high, often with a slightly forward-canted "logger" profile and a recessed edge, designed to provide stable footing on uneven surfaces.

Understanding the Trade-offs: Function Over Finesse

The design philosophy that makes the engineer boot so durable also creates inherent trade-offs that are important to recognize.

A Demanding Break-in Period

The thick, robust full-grain leather required for maximum protection is initially very stiff. This results in a significant break-in period as the leather slowly molds to the unique shape of your foot.

Limited Adjustability

While the buckle system is effective, it offers far less granular fit adjustment than a fully laced boot. This can present a challenge for individuals with non-standard foot shapes, such as high insteps or narrow heels.

Traditional vs. Modern Interpretations

Classic engineer boots are uncompromising in their focus on durability. Many modern versions, however, balance this heritage with contemporary comfort, using more flexible leathers, cushioned insoles, or lighter-weight soles. While more comfortable out of the box, these may not offer the same rugged longevity as their traditional counterparts.

Making the Right Choice for Your Goal

Selecting the right engineer boot means matching its design characteristics to your intended use.

- If your primary focus is historical accuracy and maximum durability: Seek out boots with thick full-grain leather, a Goodyear welt or stitch-down construction, and a classic, unadorned profile.

- If your primary focus is everyday comfort and style: Consider modern interpretations that may use more pliable materials, refined lasts, or combination soles for an easier break-in.

Ultimately, understanding the purpose behind each design feature allows you to select a boot that truly aligns with your expectations for performance and longevity.

Summary Table:

| Feature | Purpose | Key Characteristic |

|---|---|---|

| Laceless Shaft | Leg protection & safety | 10-12 inch tall 'stovepipe' design |

| Dual Buckle System | Secure fit without laces | Adjustable straps at instep and calf |

| Plain Toe | Durability & impact protection | Rounded, unadorned, thick leather |

| Welted Construction | Longevity & resoleability | Goodyear welt or stitch-down method |

| Heel & Sole | Stable footing | ~1.75" logger heel, rugged sole |

Ready to experience the legendary durability of engineer boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable work boots, including authentic engineer boots built to the highest standards of protection and longevity.

We can help you source or develop the perfect boot for your market. Contact our expert team today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

People Also Ask

- What future innovations are being explored for firefighting boots? Smart, Lightweight Designs for Enhanced Performance

- What should be prioritized when choosing work boots? The Ultimate Guide to Safety, Comfort & Durability

- What should workers consider regarding warranties for Chemical Resistant boots? Ensure Genuine Protection

- How does the fitting compare between pull-on and lace-up work boots? Convenience vs. Control

- What types of electrical hazard protection are available in work boots? EH vs. SD Safety Explained

- What are the main types of safety toe boots? Choose the Right Protection for Your Job

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- Why are PVC boots a good option for farm work? Unbeatable Chemical & Water Protection