When selecting chemical-resistant boots, the warranty is as critical as the materials themselves. Workers must scrutinize the warranty's fine print, specifically looking for exclusions related to the exact chemicals, concentrations, and environmental conditions they face on the job. A generic warranty that doesn't account for your specific working conditions offers a false sense of security.

The true value of a chemical-resistant boot warranty isn't its length, but its specificity. If the warranty doesn't explicitly cover the chemicals you work with, you should assume it offers no protection against premature failure from that exposure.

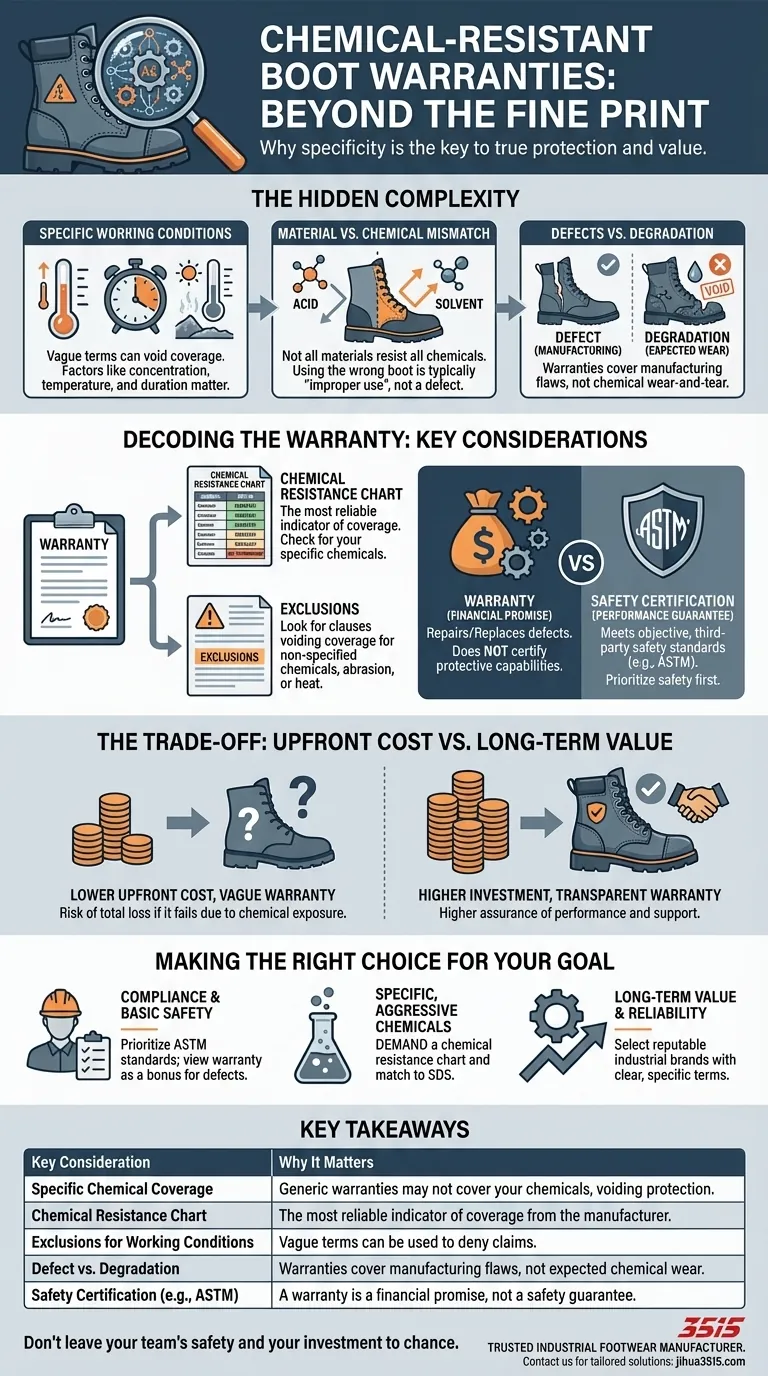

Why Warranties for Chemical Boots Are Uniquely Complex

Standard footwear warranties cover manufacturing defects under normal use. However, the definition of "normal use" is fundamentally different in environments with harsh chemicals, leading to critical exceptions and potential coverage gaps.

The Problem of "Specific Working Conditions"

Manufacturers often include clauses that can void a warranty under certain "working conditions." This vague term is designed to protect them from claims where the boot was used beyond its intended limits.

Factors like chemical concentration, temperature, and duration of exposure can all be used to deny a warranty claim if they fall outside the boot's tested parameters.

Material vs. Chemical Mismatch

A boot labeled "chemical-resistant" is not resistant to all chemicals. The materials used, such as rubber or specific polymers, have varying levels of resistance to different substances.

Using the boots against a chemical they are not rated for is a common reason for a warranty to be voided. The failure is not seen as a defect, but as improper use of the equipment.

Distinguishing Defects from Degradation

The core purpose of a warranty is to protect against defects in materials and workmanship, like a poorly stitched seam or improperly bonded sole.

In a chemical environment, it becomes difficult to prove the root cause of failure. A split seam could be a manufacturing flaw, or it could be the result of a solvent weakening the adhesive. Manufacturers will often attribute the failure to chemical degradation, placing it outside the warranty's scope.

Decoding the Warranty's Fine Print

To properly evaluate a warranty, you must move beyond the time period (e.g., "1-Year Limited Warranty") and focus on the specific terms of coverage.

Look for a Chemical Resistance Chart

The most reliable manufacturers provide a detailed chemical resistance chart. This technical document lists specific chemicals and rates the boot material's performance against them (e.g., Excellent, Good, Fair, Not Recommended).

If the chemicals you work with are not listed on this chart, or are listed as "Not Recommended," the warranty will not cover failure due to exposure.

Identify Key Exclusions

Scan the warranty document for sections titled "Exclusions" or "What Is Not Covered."

Pay close attention to language that voids coverage for exposure to non-specified chemicals, damage from abrasion or heat that accompanies chemical exposure, or any modifications made to the boot.

Understanding the Trade-offs: Warranty vs. Certified Protection

It is crucial to understand that a product warranty and a safety certification serve two entirely different purposes.

A Warranty is Not a Safety Guarantee

A warranty is a financial promise from the manufacturer to repair or replace a product that fails due to a defect. It does not certify the boot's protective capabilities.

Safety is guaranteed by certifications, such as ASTM (American Society for Testing and Materials) standards. These standards ensure the boot meets objective, third-party criteria for things like chemical permeation, electrical hazard protection, and impact resistance. Prioritize the safety certification first.

The Cost of a "Better" Warranty

Boots with a more comprehensive and specific warranty—often backed by a detailed chemical resistance chart—typically come from premium industrial brands and have a higher upfront cost.

The trade-off is clear: you can purchase a less expensive boot with a vague warranty and risk a total loss if it fails, or invest more in a boot with a transparent, technically-backed warranty that provides a higher assurance of performance and support.

Making the Right Choice for Your Goal

Before you buy, match the boot's specifications and warranty terms directly to your workplace hazards.

- If your primary focus is compliance and basic safety: Prioritize boots that meet the required ASTM safety standards for your workplace, and view the warranty as a secondary bonus for manufacturing defects.

- If you work with specific, aggressive chemicals: Ignore generic warranties and instead demand a manufacturer's chemical resistance chart, matching it directly to your workplace's Safety Data Sheets (SDS).

- If your primary focus is long-term value and reliability: Select boots from a reputable brand known for industrial-grade gear that provides clear, specific warranty terms that differentiate between defects and expected chemical wear.

By treating the warranty as a technical specification rather than a marketing promise, you ensure both your safety and your investment are genuinely protected.

Summary Table:

| Key Warranty Consideration | Why It Matters |

|---|---|

| Specific Chemical Coverage | Generic warranties may not cover the exact chemicals you use, voiding protection. |

| Chemical Resistance Chart | A detailed chart from the manufacturer is the most reliable indicator of coverage. |

| Exclusions for Working Conditions | Vague terms like "specific working conditions" can be used to deny claims. |

| Defect vs. Degradation | Warranties cover manufacturing flaws, not failure from expected chemical wear. |

| Safety Certification (e.g., ASTM) | A warranty is a financial promise, not a guarantee of safety performance. |

Don't leave your team's safety and your investment to chance.

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. We understand that a reliable warranty is built on transparent technical specifications, not vague promises.

Our production capabilities encompass all types of chemical-resistant boots, backed by clear guidance to match the right boot to your specific hazards. We help you ensure compliance, protect your workers, and maximize the value of your purchase.

Get boots with a warranty you can trust. Contact our experts today for a consultation tailored to your needs.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the essential features all work boots should have regardless of gender? Non-Negotiable Safety & Support